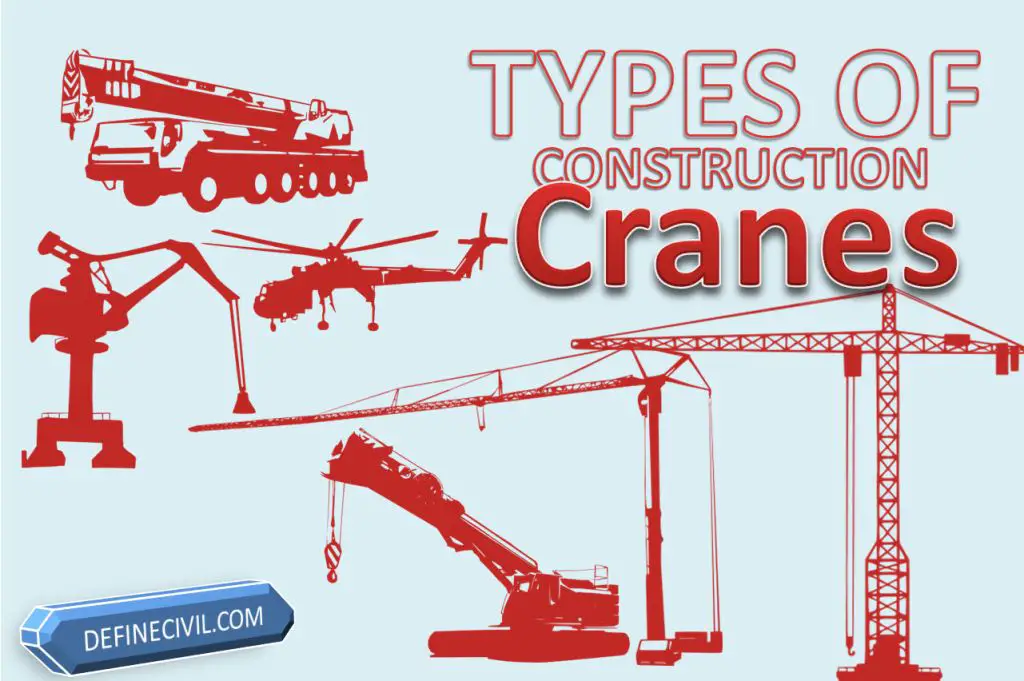

For different types of lifting jobs in construction sites there are different types of cranes each having its pros and cons and are specific for certain jobs.

So in today’s post we will be discussing in detail about the different construction crane types, their applications, advantages and disadvantages. So after reading the post you’d be at ease in selecting the type of crane perfect for your job needs.

You must be familiar with the construction of Great Pyramid of Giza in EGYPT which was completed way back in 2580 BC. It was constructed by 2.3 million blocks which were transported from nearby quarries. The granite stones that were found in king’s chamber weigh 25 to 80 tonnes which were transported from Aswan more than 800 KM far.

The total of 5.5 million tonnes of limestone, 8,000 tonnes of granite and 500,000 tonnes of mortar were used in the construction of the Great Pyramid. This colossal structure was built manually by labors that used the carts for shifting and lifting of these heavy stones.

If such type of structure could have built in 21st century it would be very easy, just because of cranes that we have now at the construction sites for manage heavy lifting jobs which otherwise would be impossible for man.

A crane is a hoist machine also termed as Derrick or Gantry it comprises of pulleys and wires and are operated hydraulically or electrically for lifting equipment by following the simple principles of mechanics and load equilibrium.

Cranes were once operated by steam engines are now replaced with efficient and more productive hydraulic and electric engines. With the better understanding of lifting mechanisms the hoist height and weight capacities have been increased considerably over recent decades.

Types of Cranes (A BIG LIST)

Here’re some common types of cranes.

- Telescopic Cranes

- Overhead Gantry Crane

- Mobile Cranes

- Tower Cranes

- Truck Mounted Crane

- Rough Terrain Crane

- Loader Crane

- Floating Cranes

- Harbor Cranes

- Crawler Cranes

- All Terrain Crane

- Level Luffing Crane

- Telescopic Handler Crane

- Aerial Crane

- Rail Road Crane

[su_box title=”Must Read”]The above are the different types of cranes used in construction but if you are looking for different types of “LIFTS” that are used in construction works than read the below article. Types of Construction Lifts[/su_box]

-

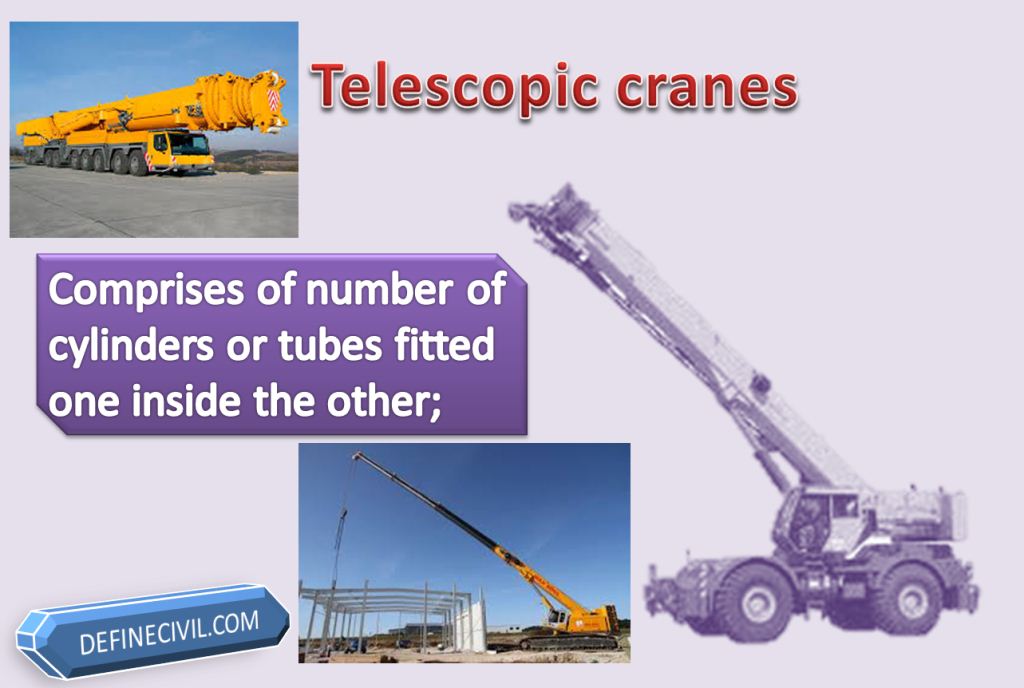

Telescopic Cranes

Telescopic crane has boom comprises of number of cylinders or tubes fitted one inside the other; when required these cylinders are extended by powering with the help of hydraulic mechanism. Because of telescopic cranes the height adjustment during hauling is now not a problem. Telescopic cranes are of heavy form of cranes to transport and maneuver objects from one place to another and are used for small scale construction projects, lifting boats and at ports.

-

Overhead Gantry types of Cranes

Gantry crane is a crane that is built overhead of a frame work called gantry and is used to span on an object or workspace. These cranes are used in hydro-mechanical gate fixing, automobile shops for lifting engines and parts. Gantry crane is sometimes also termed as overhead crane or portal crane. The word portal represents the empty space that is spanned in between the gantry framework.

-

Mobile Cranes

Cranes were originally fixed to a position and before 1870 the crane was always expected to be a fixed element. But now we have mobile cranes that are mounted on carriers and trucks that are either crawlers or rubber-tired vehicles. Self-propelled models of mobile cranes are also being designed that need not to mount on any vehicle and have full-fledged capability of movement. Truck mounted mobile cranes are used for bridge construction whether it is for launching of concrete girders or transporting bundles of steel bars or fixing of heavy duty formwork these mobile cranes are now a days very common in construction projects.

Mobile cranes have telescoping booms like in telescopic cranes and are designed to reach anywhere at site or even transport to a site. At the end of the boom a hook is suspended with the help of wire or sheaves.

Based on the requirements and prerequisites of the project there are variety of cranes available to select from. Mobile cranes can be hydraulic cranes, all terrain cranes, rough terrain cranes, crawler cranes (also called self-propelled cranes), Carry Deck Cranes. In most of the cases the length of the boom for mobile crane varies between 33 to 40 meters.

Here is a video preview of mobile Cranes:

-

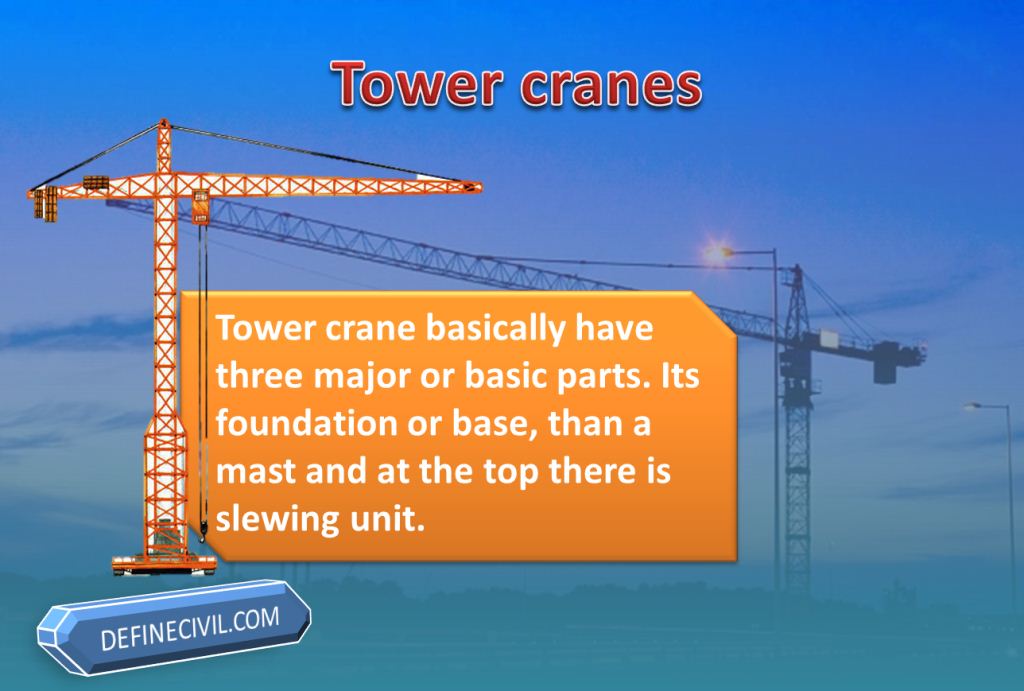

Tower Cranes

If you are opting a crane for a mega project than you can’t miss tower crane from your list of options. Why? Because I have worked on many mega projects and I always wonder that if tower cranes would not have invented how we would be able to create such sky scrapers or dams etc.

The tower cranes are used to lift every sort of tool or equipment from as small as a generator to as large as a small crane. While reading about the tower cranes; there are many interesting questions going through our mind like; how this so-long boom is able to lift such heavy equipment’s without tipping over? How this tower crane gets lifted as the building grows taller? Well first we should talk a bit about the structure of tower crane because only than we would be able to understand how tower crane works?.

Tower crane basically have three major or basic parts. Its foundation or base, than a mast and at the top there is slewing unit.

The base or foundation is actually a concrete slab in which the bolts for the tower cranes are embedded for fixing the tower crane. Sometimes the tower crane is also attached to the sides of the structure. Anyhow, the next part is called the mast; mast is basically nothing but the tall tower you see between rotating slewing unit and the foundation. It consists of framed steel structures that are attached one after the other to achieve the required height as the construction progresses.

At the top of the mast is the slewing unit that is equipped with a motor and a gear with the help of which it can rotate when required. On the slewing unit three parts are attached one is the operator’s cab and ahead of that is the long horizontal jib which is also termed as working arm. Behind the operator’s cab is the short counter-jib with which the counterbalancing weights are fixed following the basic principle of equilibrium.

The tower crane can reach to a heath of 8- meters with boom length of 70 meters. The lifting capacity can go up to 20 tons. The lifting capacity of the tower crane also depends on the distance from the crane mast. You can’t expect to carry 20 tons of load when you need to go as far as 60 meters away from the mast.

The tower crane is fixed with two limiting switches. One is called maximum load switch and other is called load moment switch. These switches are fixed to alarm the operator’s about any overloading or more load being carried away from the axis of the crane.

-

Truck Mounted Crane

Truck mounted crane is actually a type of mobile crane. It is not self-propelled rather it is fixed / mounted on the truck to reach different parts of the site when required. It can have a boom length between 14 to 22 meters and can carry load up to 20 tones. The booms of the truck mounted cranes are either stiff booms or knuckle boom that has a hinge at the mid for easy adjustment while reaching the length required.

It is best suited for jobs where a delivery work along with loading and unloading work is to be done simultaneously. When a truck delivers a product you need not to wait for any other crane for unloading the material. The truck mounted cranes can be used for fixing of steel structures like roof trusses, or loading / unloading of the oil storage tanks, concrete panels, road barriers etc.

-

Rough Terrain types of Cranes

Rough Terrain Crane is a self-propelled mobile crane that works by using hydraulic principles. As the name suggests this type of crane is best suited for rough surfaces and off-road applications. Rough terrain cranes are used in large scale construction and infrastructure projects like bridges, power and chemical plants, refineries etc. Rough terrain cranes are powered by a single engine that powers both the undercarriage and the crane. The undercarriage is the carrier on which the crane is mounted.

To stabilize the undercarriage outriggers are extended horizontally and vertically. It is best suited for lift and go operations.

-

Loader Crane

Loader crane can be called as a heavy duty truck mounted crane. The loader cranes are used for loading the trucks, vehicles and heavy duty panels or equipment to transport and shift to site. These are best suited for load-travel-unload operations. With the help of loader cranes you don’t have to hire both truck and crane; it works for both of the jobs.

Some loader cranes can have boom lengths of up to 17 meters. These cranes are specifically used at sea ports for shifting containers and as they can do the haulage job so you don’t need to hire trailers etc.

Loader cranes are also termed as articulating crane and in most of the cases it had a knuckle-boom which is electrically powered by the truck or trailer.

-

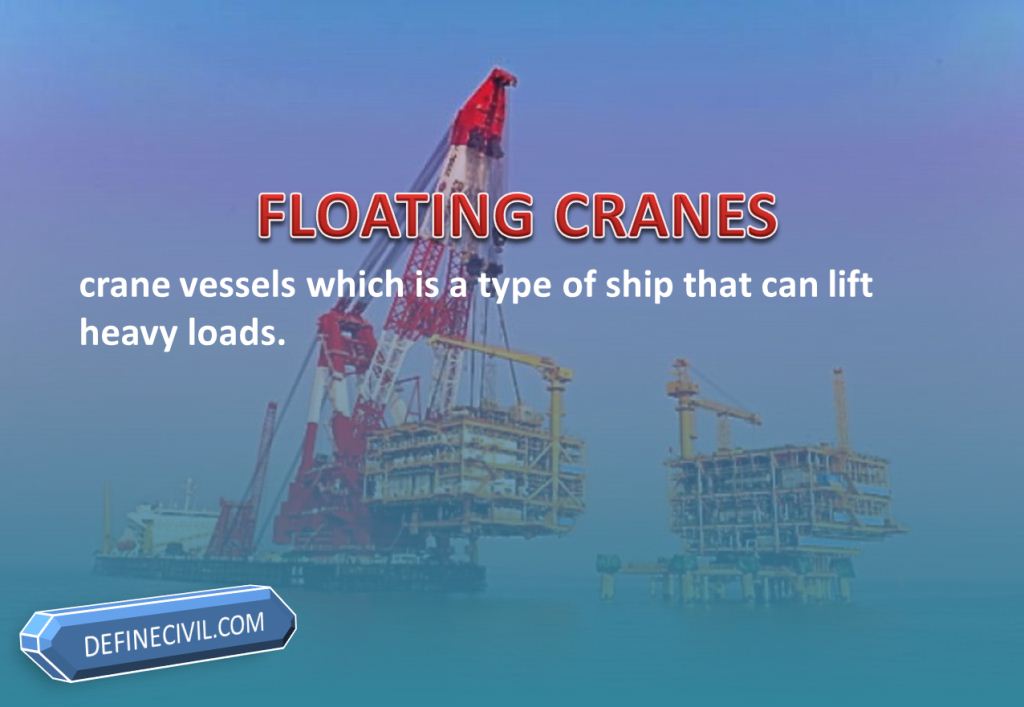

Floating Cranes

Floating cranes are actually crane vessels which is a type of ship that can lift heavy loads. These crane vessels or floating cranes are a must to have in offshore construction projects. These floating cranes are also used while bridge building and port construction. The floating cranes have also been used to salvage sunken ships.

-

Harbor Cranes

Harbor cranes are actually giant cranes that plays a very important part in harbor logistics. They are efficient in loading and unloading of cargo at the ports. In order to speed up the loading process the harbor cranes have double tread-wheels unlike the construction cranes. The harbor cranes can carry load between 2 to 3 tons.

-

Crawler Cranes

Crawler cranes are among the principle types of mobile cranes. The crawler crane has an undercarriage that is fitted on a set of crawler tracks. These crawler tracks provide it the stability and mobility for accessing difficult terrains. Crawler crane is a self-propelled crane and is equipped with either a lattice boom or a telescopic boom.

Due to the crawler tracks it can work on areas where no work is done for stabilizing the surface. For the crawler cranes the stability makes it to operate without the use of outriggers. But one of the drawback of the crawler crane is that it is too difficult to transport the crane from one site to the other because of its great weight and size.

-

All terrain cranes

All terrain crane is one of the fines type of mobile crane on the planet. It is made by combining the advantages of a truck-mounted crane and a rough terrain crane. The truck mounted crane can travel at fast speed but it is unable to carry heavy loads and it can’t move on rough terrains. The rough terrain crane can’t travel at fast speeds. So combining the speed and maneuverability of both the cranes; the all-terrain crane is best suited for fast and efficient lifting work. The all terrain crane can carry load upto 1,200 tonnes.

The all terrain crane can operate on various types of surfaces and under various weather conditions. The crane has all-wheel drive steering system that can easily move through sand and gravel as well as smooth travel on asphalt roads and highways with speed of over 88 km per hour.

These all-terrain cranes are best suited for remote construction sites where access road is not there. They can be used for heavy lifting jobs like erection of wind turbines, lifting of heavy pre-cast concrete building segments.

-

Level Luffing Crane

One of the most difficult aspect while working with cranes is to carry load in a leveled manner. Like in the construction industry or in shipbuilding the load is required to be lifted near ground level in a steady manner without much disturbance. For such types of work this type of cranes is very vital.

In level-luffing cranes the hook remains at the same level while the jib or arm of crane is moved upward and downward due to which the hook is moved inward or outward; which is called luffing movement.

Level luffing crane is also termed as luffing jib crane and is the must to have while working in shipyard and port industry.

-

Telescopic Handler Cranes

You might have seen wheeled loader or backhoe loader as a mean of picking up different heavy equipment from one place of site to the other readily when a fully operative crane is not available. The limitation with the loader here is that it doesn’t have jib or boom attached to it for reaching the spots far away from the lifting position.

So thanks to the telescopic handler crane that has solved this limitation. A telescopic handler crane has a single telescopic boom or an articulating boom that can extend forward and upward from the vehicle. At the end of the boom different attachments can be fixed like a bucket or a grab for ease in lifting different objects.

These telescopic handler booms are also named as telehandlers and find its application in agriculture, construction and various other industries for small and instant lifting jobs. One of the biggest drawback for the use of telescopic handler crane is that the lifting capacity reduces significantly as the working radius is increased causing the vehicle to become unstable, despite counterweights in the rear.

-

Aerial types of Cranes

An Aerial crane is nothing more than a helicopter that is used for the lifting of heavy awkward loads. These types of cranes are generally not common as they are only feasible and economical in special situations when the work is to be carried out in between tall building or near hill or mountains that is far from the near roads.

One of the broadest application of the aerial crane is for lifting of large cut trees or logs from the cutting spot to the place that is accessible by vehicles.

-

Rail Road types of Cranes

A rail road crane is a self-propelled crane or crane that can be moved by a locomotive, consists of a rotating crane body that is mounted on a chassis that is fitted with flanged wheels. The jib is attached to the crane body that works all the way for lifting and operating mechanisms. The railroad crane is mostly used in lifting of cargo or goods, maintenance of the rail ways or during accident recovery works.

So I have covered all the types of cranes that are currently being used for various types of lifting jobs. Please share this article as it is an interesting one and I bet most of the types would be unknown by your friends so tell them that you have found something new and interesting.