The compaction factor test is done to check the workability of concrete, on the basis of weight ratio between partially compacted to fully compacted concrete.

We can’t use the slump test for low workable concretes. Concretes we mostly use in mass dam structures or road pavements have significantly low values of slump. For all such concretes, compaction factor test give accurate assessment of workability.

Civil Engineers recommend this test for concretes when the slump value is less than 50 mm and for concrete mixes where compaction is to be carried out by vibration.

This test is particularly designed for the concrete whose workability is less and cannot be determined by usual slump test.

Compaction factor test is to check the workability of concrete in the laboratory. But you can also use this test in the field as well. Anyhow, the test procedure was originally formulated by United Kingdom based Road Research Laboratory.

Background of Compaction Factor Test

Compaction factor test works on the principles of determining the degree of compaction. The special apparatus of compaction factor test allows the concrete to fall under standard heights. Afterwards, the degree of compaction and the compaction factor is measured by the density ratio.

Suitability of test

This method of slump determination is suitable for:

- Plain concrete

- air-entrained concrete

- light weight, normal weight, or heavy weight aggregates concrete

This method is not suitable for

- Concrete mixes with aggregate size of more than 38 mm

- Aerated concrete

- no-fines concrete

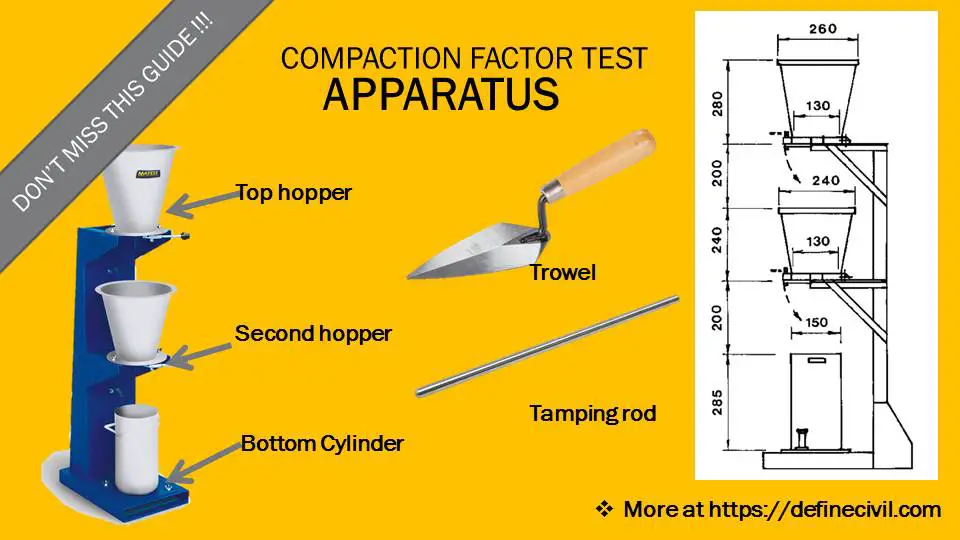

Apparatus:

Let’s now look at the apparatus you need:

The apparatus for compaction factor test comprised of two cone shaped hoppers made up of brass or bronze. Their lower ends are fixed with tight hinge openings ideal for quick release and catch.

These hoppers are attached with a bottom cylinder on a particular axis.

A steel rod with dimension of 61cm (length) x 1.6cm (diameter) is used as reference to level the concrete.

You also need a weight balance to measure the weight of concrete samples and empty weight of concrete cylinder. Make sure the balance is able to weigh upto 1 gram.

You need a hand shove to handle concrete sample.

Standard of the test

We carry out test as per IS 1199:1959 – Method of Sampling and analysis of Concrete (Eleventh Revision) Reaffirmed – Dec. 2013.

Sampling:

For field based test, always use freshly mixed concrete. If the concrete contains aggregates of more than 38mm, then it must be sieved through a small pore size screen to get rid of bigger particles.

For field based sampling, premix concrete is used.

Procedure:

- Be sure that conical hoppers are free of moisture. Apply grease to the sides and close the trap door of the top hopper.

- Now scoop the concrete sample to be tested gently in the top most hopper and fill it up to its brim with the help of a hand scoop. Now level the top surface properly.

- Cover the brim with the lid.

- Now open the hinge trap doors of this filled hopper to allow the concrete to fall freely in to second hopper.

- The mixture may sometime stick to the upper or bottom hopper. Use rod to push it gently into the hopper from its sides.

- Keep the bottom most cylinder covered with trowel during the process of rodding.

- Now uncover the cylinder and allow the trap doors of the bottom hopper to be open up and let the concrete fall in to the bottom most cylinder.

- Level the concrete in the cylinder by cutting off the excess with the help of trowels and level it with rod.

- Gently clean the external surface of the cylinder.

- Now weight the cylinder to the nearest 10 g with concrete in it. This weight will be considered as weight of partially compacted concrete (W1).

- Remove the concrete and empty the cylinder. Fill it up again and again with the same sample mixture in the form of layers, each layer about 5 cm deep every time and fully rammed to ensure the tight compaction of concrete particles.

- Again level the cylinder with rod every time

- Weight the cylinder when filled with fully rammed concrete. This will be weight during full compaction (W2).

- At the end, or at the start of procedure make sure to measure the weight of empty cylinder as well. This will be (W).

Precautions

Here’re some points you should watch out for:

- Be sure that you carry out procedure of the test in area that is free of vibration or shock.

- Make sure to clean the inner surface of the apparatus hoppers.

- Make sure to remove the excess concrete from the top of cylinder by holding a trowel in each hand.

Advantages:

- It is used for testing workability in laborites.

- The concrete, which is having low workability, this test is reliable.

- For a wide range of work, it is reliable to check and detect variation workability.

- As compare to the Slump test, a compaction test is used for more accurate information and results related to compatibility.

- Compatibility test is more appropriate than static test for a much highly low-viscosity concrete mixture and is a dynamic test.

- This test is much precise and sensitive test.

- The test is dynamic and thus is more suitable for the concrete mixture.

Disadvantages:

- The enormous and weighty nature of the device reduces its effectiveness in the field. Furthermore, the test method needs an equilibrium to measure the mass of concrete in the cylinder.

- The quantity of work applied to the concrete being tested is friction in between the concrete and the hopper, which may don’t reflect the additional condition.

- This test is commercially available and is often utilized.

[su_table responsive=”yes”]

| Sr. No. | Description | Sample 1 | Sample 2 | Sample 3 |

| 1 | Weight of Empty Cylinder (W1) | |||

| 2 | Weight of Empty Cylinder + Free Fall Concrete(W2) | |||

| 3 | Weight of Empty Cylinder + Hand Compacted Concrete (W3) | |||

| 4 | Weight of Partially Compacted Concrete(WP = W2 – W1) | |||

| 5 | Weight of Fully Compacted Concrete(WF = W3 – W1) | |||

| 6 | Compaction Factor = WP/ WF |

[/su_table]

Calculation:

The compaction factor is described as the ratio of the weight of partially compacted concrete to the weight of complete compacted concrete.

[su_service title=”Note” icon=”icon: pencil” icon_color=”#227f24″]Compacting factor = (weight of partially compacted concrete) / (weight of fully concrete) = (w2 – w1) / (w3 -w1)[/su_service]

Here,

W1 = weight of empty cylinder.

W2 = weight of partially compacted concrete.

W3 = weight of complete concrete.

If the compaction factor value is close to 0.7, this concrete is suitable for road pavement and value of about 0.95 shows highly strengthened concrete.

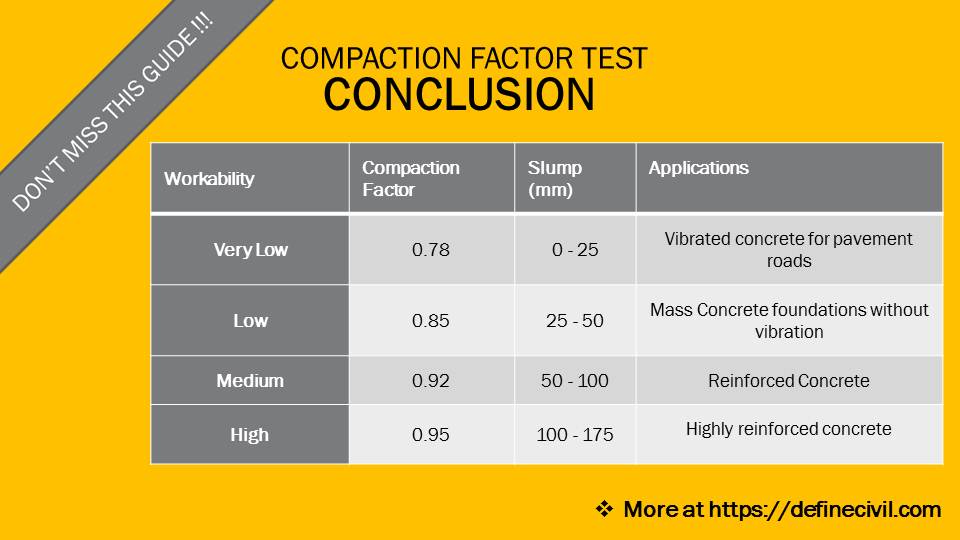

Conclusion:

The normal range of the concrete compaction test ranges between (0.8 – 0.92). The test is reliable for the dryer mixes, for which the slump test is not accurate and satisfactory.

The sensitivity of the compaction factor is decreased outside the normal range of workability, and this is generally inaccurate or unsatisfactory for compacting factor greater than 0.92.

Relationship between workability and slump

[su_table responsive=”yes”]

| Workability | Compaction Factor | Slump (mm) | Applications |

| Very Low | 0.78 | 0 – 25 | Vibrated concrete for pavement roads |

| Low | 0.85 | 25 – 50 | Mass Concrete foundations without vibration |

| Medium | 0.92 | 50 – 100 | Reinforced Concrete |

| High | 0.95 | 100 – 175 | Highly reinforced concrete |

[/su_table]

[su_box title=”Appeal – Help US” box_color=”#0092c4″ radius=”9″ id=”social_definecivil”]We’re providing you useful civil engineering resources since 2019. Please help us by subscribing to our youtube channel. It’ll take just your two seconds but would help us in spreading the message and helping the cause.

[su_button url=”https://www.youtube.com/c/saadiqbalengr?sub_confirmation=1″ target=”blank” style=”3d” background=”#ae2c1b” size=”5″ center=”yes” icon=”icon: youtube-play” text_shadow=”0px 0px 0px #000000″]Subscribe our Youtube Channel [/su_button]

[/su_box]