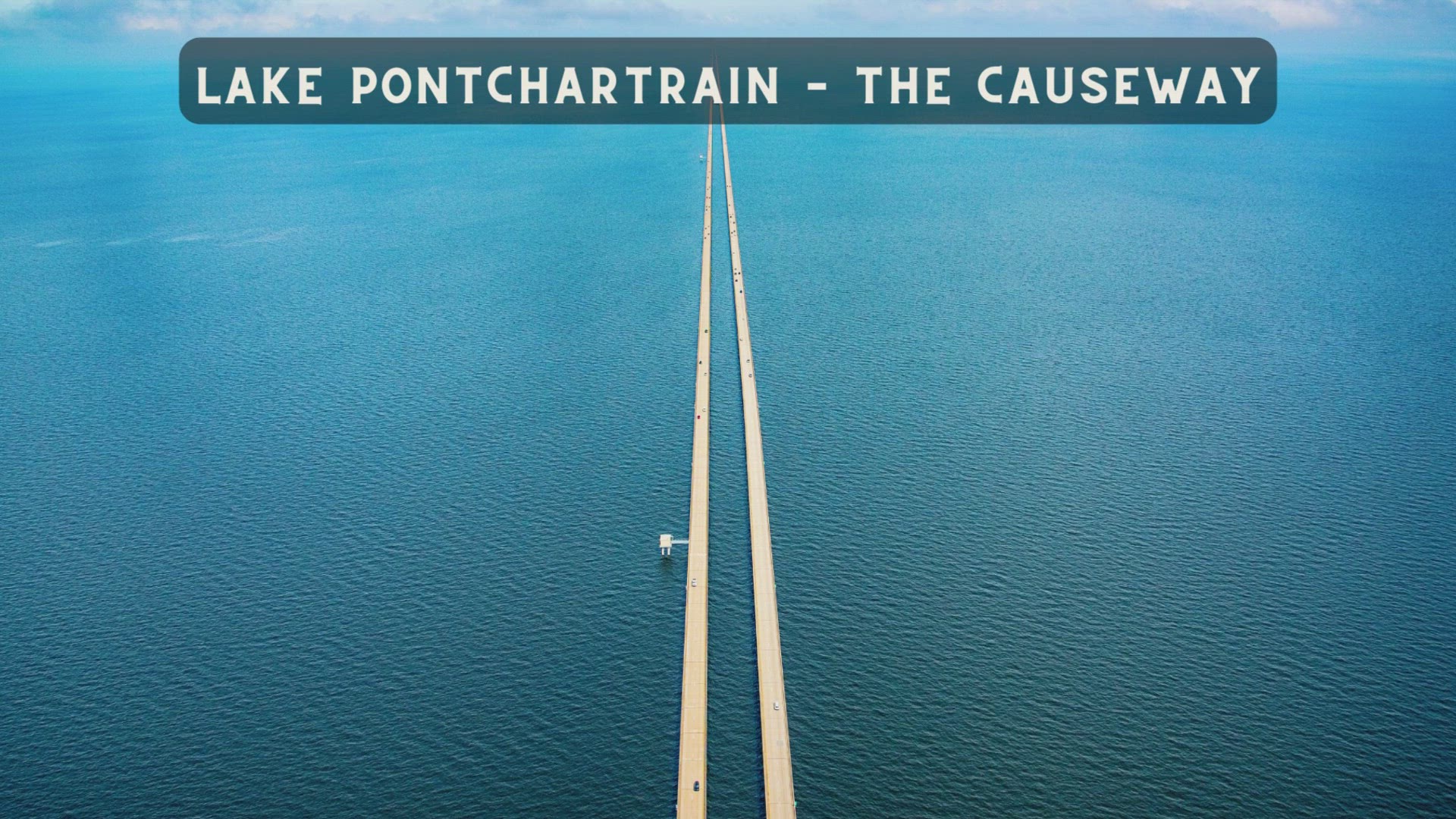

Longest Bridges of United States

4K views · Sep 8, 2022 definecivil.com

Being a bridge enthusiast, I’m always after some fascinating and long span bridges. United States has got some of the longest bridges in the world over water. Some are even more than 36 kilometers in length. So, if you’re also a bridge lover or are involved in construction of bridges; get ready to enjoy some Goosebumps. The longest of bridges in America is in Louisiana along the interstate Highway system. It’s over 22.80 miles (36 km) with height of above 15 meters in length. It is in fact one of the longest bridges in the world over water and yet it’s toll-free. Louisiana is a state famous for cultural heritage, music, and cuisines; but it’s also known for its state-of-the-art infrastructure, bridge, buildings, and other hallmarks.

Types of stones used in construction - (Properties & Com...

8K views · Sep 10, 2022 definecivil.com

A lot of civil engineering projects like building construction and commercial construction use stone as a basic construction material. Due to their toughness and durability, stones are like high-end construction material. Whether it is a road, a building, a bridge, a retaining wall, or any kind of construction project - stones serve significant purposes. There are various types of stones which are typically classified on the basis of their formation and origin. On the basis of geological classification, stones or rock used in construction are igneous rocks (basalt, diorite, granite, rhyolite), sedimentary rocks (lime stone, sandstone, and dolomite), and metamorphic rocks (quartzite, marble, slate, and gneiss). </strong></p> Different factors such as compressive strength, crushing strength, hardness, impact value, and impermeability play a vital role in determining a particular type of stone to deliver a specific goal. Some stones like granite and basalt are famous because of their enhanced strength and durability but at the same time other type of stones like gneiss are perfect for decorative applications. For massive construction projects like dams and bridge piers, we need stones with high compressive strength like sandstone, granite, and basalt. So, it is important to know the purpose and pros of a specific type of stone to utilize it for the right type of application. Read entire article: [types of stone in construction](https://definecivil.com/types-of-stones-in-building-construction/) Subscribe us on youtube: [youtube](https://youtube.con/c/saadiqbalengr) Like us on facebook: [facebook](https://facebook.com/definecivilfb) Follow us on twitter: [twitter](https://twitter.com/iamcivilengg)

Weight of Concrete, density of concrete explained

53K views · Dec 28, 2021 definecivil.com

Weight of Concrete, density of concrete explained

Removing Paint from Concrete

2K views · Dec 26, 2021 definecivil.com

In this Video, I have explained in depth the steps you can use to remove paint from concrete with or without chemicals.

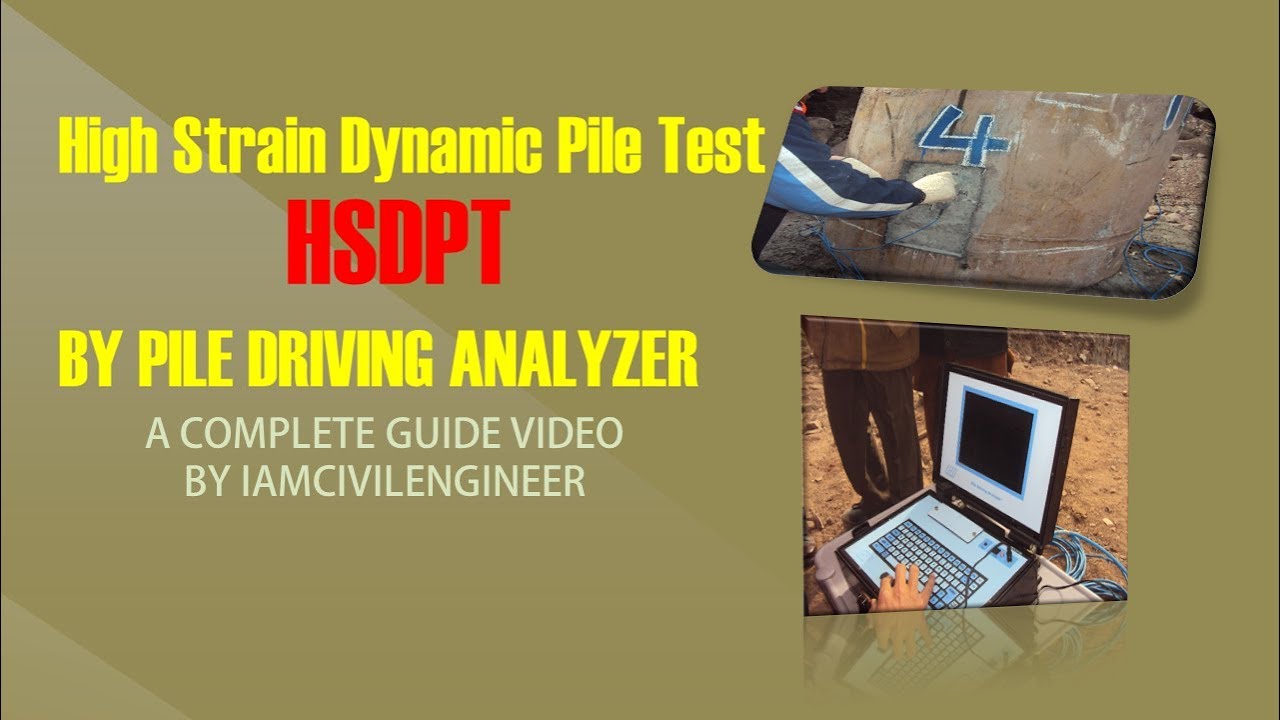

High Strain Dynamic Pile Testing by Pile Driving Analyzer

3K views · Oct 30, 2021 definecivil.com

High Strain Dynamic Pile Testing is an alternate pile testing technique which takes less time for test preparation and conducting, compared to the conventional static pile load test. This test method is used to obtain the force and velocity through measured strain and acceleration induced in a pile during the impact of an axial force. This test method is suitable for all type of deep foundation units i.e. pile or any other type of similar nature whether cast-in-situ or driven type. One of a very significant advantage of the High Strain Dynamic Pile Testing is its performance in non-destructive manner which not only save times but surely cut back the testing cost significantly. The following PDA results are typically obtained on site: Mobilized Static load capacity based on CASE method Pile Integrity – location and extent of damage. Driving stresses –maximum compression / tension forces at pile top/toe Hammer performance-maximum energy transferred to pile. ============================ Read Complete Article here https://www.iamcivilengineer.com/2018/08/high-strain-dynamic-pile-testing.html * Visit our Blog https://www.iamcivilengineer.com * Subscribe to our Channel https://www.youtube.com/c/saadiqbalengr * follow us on twitter https://www.twitter.com/iamcivilengg * follow us on facebook https://www.facebook.com/iamcivilengineerdotcom

Grillage Foundation - A Super Interactive Explainer Video

44K views · Oct 30, 2021 definecivil.com

So, in my this video, I've tried to make it super interactive in explaining everything about Grillage Foundation. If you don't know what is grillage foundation or how we can construct a grillage foundation or even what are some important design aspects; this amazing video is a definite help. #Grillage_Foundation #Foundation_Engineering #Foundation #Grillage Starting from the definition that it's a shallow foundation where one, two or more tiers of steel beams are superimposed on a layer of concrete, adjacent tiers being placed at right angles to each other, while all tiers are encased in concrete. It is the most economical foundation in case of transferring heavy loads from columns to soil of low bearing capacity.Please Note that the word tier is used for such an arrangement in which items are placed in layers one above the other like the seats that are placed in a cinema or auditorium. In United states, this type of footing is used for electrical transmission line projects. It is suitable where bedrock is not available and raft foundation is not feasible. The structural design of such a foundation makes it ideal for electrical transmission line projects. For more details please don't forget to read our in depth article here: https://www.iamcivilengineer.com/what-is-grillage-foundation-definition/ ==================== Support Us Please ==================== If you've liked this video, please don't forget to subscribe to our channel so that you can get notified when our new video is online. We're committed to provide technical perfect knowledge of civil engineering and construction to our community. ============================ Subscribe us Now ========================= https://www.youtube.com/channel/UCUW7dpFm5vmYr2FdKpiEQxA *** WEBSITE https://www.iamcivilengineer.com *** FACEBOOK https://facebook.com/iamcivilengineerdotcom *** TWITTER https://twitter.com/iamcivilengg

5 Famous Foundation Failures in Building

823 views · Oct 30, 2021 definecivil.com

In this video I've explained some of the famous building foundation failures that have allowed us to learn new horizons of geotechnical engineering. ================== Foundation Failure ================== A foundation failure is when it is no longer able to support the full weight of the building due to movement of soil and excessive settlement. In such cases, the building may sink or may topple over altogether due to inadequate bearing capacity. Many foundation fail just because of improper assessment of soil conditions existing to the site. In some cases the buildings are constructed on marginal land due to lack of suitable land. ========================== Causes of Foundation Failure ========================== The failure of foundation may be due to poor design, faulty construction, and overloads. The causes of foundation failures are: Construction error Improper soil investigation Fluctuation of ground water table Seismic loads #Foundation_Failure Don't forget to read a complete article about standard proctor test on definecivil.com here: ====================================== https://definecivil.com/standard-proc... ========================================= * Visit our Blogs https://www.iamcivilengineer.com https://definecivil.com * Subscribe to our Channel https://www.youtube.com/c/saadiqbalengr * follow us on twitter https://www.twitter.com/iamcivilengg * follow us on facebook https://www.facebook.com/iamcivilengineerdotcom

Field Density Test (FDT) Methods - Procedure - Comparison

16K views · Oct 30, 2021 definecivil.com

In this amazing video, I've tried to explained the various methods of field density test (FDT) that are performed in the field keeping in view the different types of soil. It explains all methods like Sand Replacement method, core cutter method, rubber balloon method, nuclear density test method, and water replacement method. It explains which method is suitable for particular type of soil and what are the pros and cons of it. So, if you're in the field and are left with the situation when you have to decide the method of FDT for your project, this video will be a worth to watch. I've also written a detailed article on the same subject, on my blog at Definecivil.com the link is https://definecivil.com/field-density-test/ #field_density_test, #FDT, #Sand_replacement_method #Core_Cutter_method #nuclear_density_test_method #rubber_balloon_method, #water_replacement_method ==================== Support Us Please ==================== If you've liked this video, please don't forget to subscribe to our channel so that you can get notified when our new video is online. We're committed to provide technical perfect knowledge of civil engineering and construction to our community. ============================ Subscribe us Now ========================= https://www.youtube.com/channel/UCUW7dpFm5vmYr2FdKpiEQxA *** WEBSITE https://www.iamcivilengineer.com *** FACEBOOK https://facebook.com/iamcivilengineerdotcom *** TWITTER https://twitter.com/iamcivilengg

!['Video thumbnail for Bitumen Extraction Test [APPARATUS, PROCEDURE, CALCULATION]'](https://streaming.humix.com/poster/iOTxbxZFzyqFksYH/081f5b22a28818ccaccd9eca37d3b626de1498fa48c1b6519e108911bcab3665_wJkWwO.jpg)

Bitumen Extraction Test [APPARATUS, PROCEDURE, CALCULATION]

30K views · Oct 30, 2021 definecivil.com

In today's video I have explained in detail about the Bitumen Extraction Test used to carry out the binder content in asphalt. Bitumen Extraction test is used to determine the amount of bitumen that is actually used as binding content in asphaltic pavement or asphaltic concrete recently laid at site. The durability, compatibility and resistance from defects like rutting, bleeding, raveling and ageing of flexible asphaltic roads is highly dependent on the amount of the bitumen used for the coating of the filler aggregates used in the asphaltic matrix. So this test is parallel to that of the cylindrical compression test of the actual concrete samples obtained at site before placement of concrete to determine its actual compressive strength to be as per the required mix design. The mix design of asphalt is carried out by series of hit and trial in job mix formula for determination of the optimum binder content. So at site, before final payment to the contractor it must be ensured that the amount of bitumen required by the mix design is actually used at site or not. ============================ Read Complete Article here https://definecivil.com/bitumen-extraction-test/ * Visit our Blog https://www.iamcivilengineer.com https://definecivil.com * Subscribe to our Channel https://www.youtube.com/c/saadiqbalengr * follow us on twitter https://www.twitter.com/iamcivilengg * follow us on facebook https://www.facebook.com/iamcivilengineerdotcom

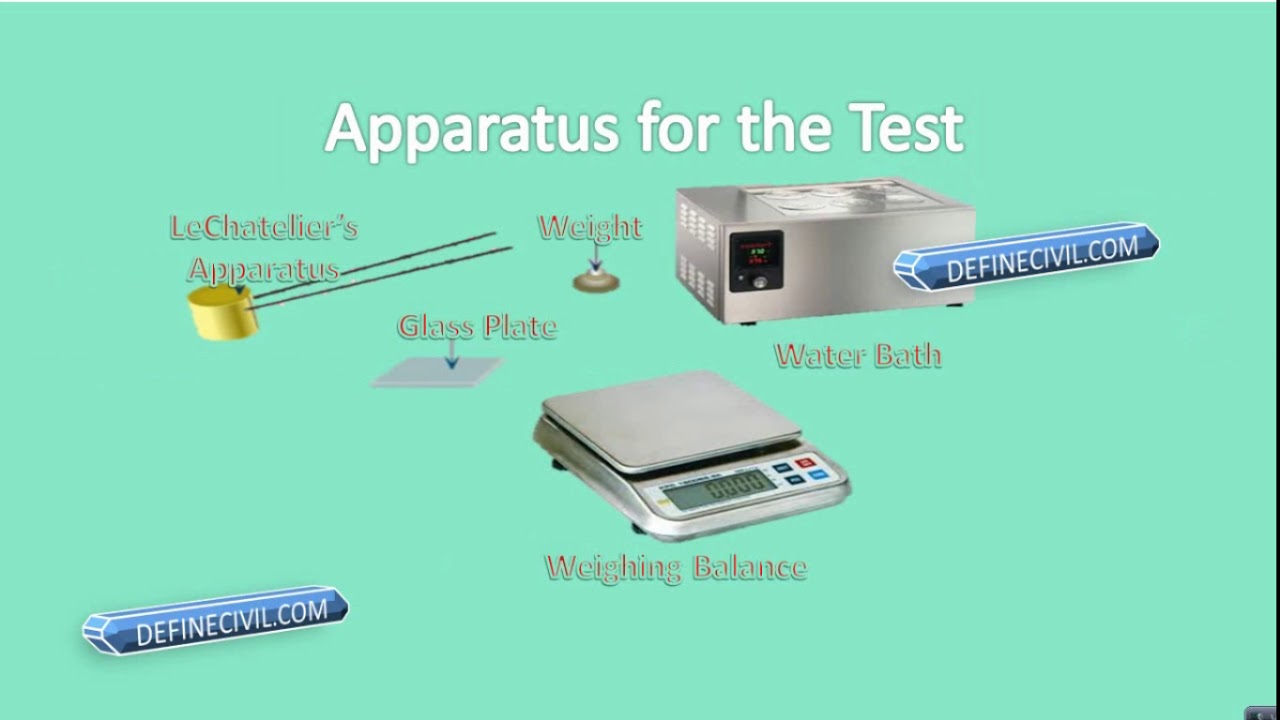

Soundness Test of Cement by Le Chatelier's Method

3K views · Oct 30, 2021 definecivil.com

Soundness test of cement by Le-Chatelier apparatus is very easy but very important test along with many other quality tests on cement. Before going to the exact details, procedure and calculations of soundness test of cement by Le-Chatelier apparatus, let’s first discuss about the overview of soundness. As an engineer what behavior do you expect from a structure that swells when gets hardened? Have ever you heard or witnessed water supply lines being blown out in winters due to icing of waters therein? So if you answer to above questions you would know how destructive the unsoundness is. The word soundness has a meaning of reliability and trustworthiness so in a rigid construction material like concrete; the soundness is an imperative property. Before performing the soundness test of cement by LeChatelier’s Apparatus the standard consistency of the cement paste must be determined by using standard method test. After finding the amount of water that is required for the preparation of the cement past of standard consistency, the test is commenced. First of all the mould of the Le-Chatelier’s apparatus and the glass plates are applied slightly with some oil so that the cement past could not get stuck with them. A sample of 200 grams of cement is taken in a bowl properly weighed with the help of physical balance. The weighed sample can be placed in a mixing tray along with a pit made within it for addition of water. After that 0.78 times the weight of water required for standard consistency is taken in a jar. The water is then added to it and the cement paste is uniformly mixed with the help of showels. After that the oiled Le-Chatelier’s mould is placed on an oiled glass sheet and the cement paste is added in it. After filling the mould the other small glass sheet is placed on top of it and some weight is placed so that the assembly may not get disturbed. The assembly is then placed in a water bath at room temperature i.e. 27 ± 20 C for a period of 24 hours after which it is removed and the distance between indicator needles is noted with the help of measuring scale up to 0.5 mm accuracy. Note this reading as D1. After that the assembly is then placed in water bath and is heated up to boiling point for 25 to 30 minutes and is then kept there for 3 hours after which it is allowed to cool up to room temperature. Again the reading of distance between indicator needles is noted as D2. ======================================== Read Complete Article here https://definecivil.com/soundness-test-of-cement/ * Visit our Blogs https://www.iamcivilengineer.com https://definecivil.com * Subscribe to our Channel https://www.youtube.com/c/saadiqbalengr * follow us on twitter https://www.twitter.com/iamcivilengg * follow us on facebook https://www.facebook.com/iamcivilengineerdotcom

Fineness test of Cement Test

28K views · Oct 30, 2021 definecivil.com

Fineness test of cement is another quality control parameter that experts keep in check of at the laboratory. The size of the particles of OPC impact the surface area and the heat of hydration. Fineness of cement is an important physical property of cement that defines the particle size and the surface area of cement particles. It is expressed in %age when determined as a modulus with sieving or units of cm2/gm or m2/kg in case when determine by Blaine air permeability apparatus. #fineness_test_of_cement #fineness_test #cement_fineness #fineness_of_cement #physical_properties_cement Fineness modulus is an empirical figure that is determined in the laboratory to express the total percentage of the sample of cement retained on a 90 micro meter size sieves divided by 100 as averaged. The fineness of cement indirectly impacts the rate of hydration and thus heat of hydration. Now when you mix cement with water a layer is formed around the particles. The smaller the particles, the more the surface area, and the water requirement for hydration reaction. Don't forget to share, like, and hit subscribe button. Here's the original article: https://definecivil.com/fineness-of-cement-definition-test/ ==================== Support Us Please ==================== If you've liked this video, please don't forget to subscribe to our channel so that you can get notified when our new video is online. We're committed to provide technical perfect knowledge of civil engineering and construction to our community. ============================ Subscribe us Now ========================= https://www.youtube.com/channel/UCUW7dpFm5vmYr2FdKpiEQxA *** WEBSITE https://www.iamcivilengineer.com *** FACEBOOK https://facebook.com/iamcivilengineerdotcom *** TWITTER https://twitter.com/iamcivilengg