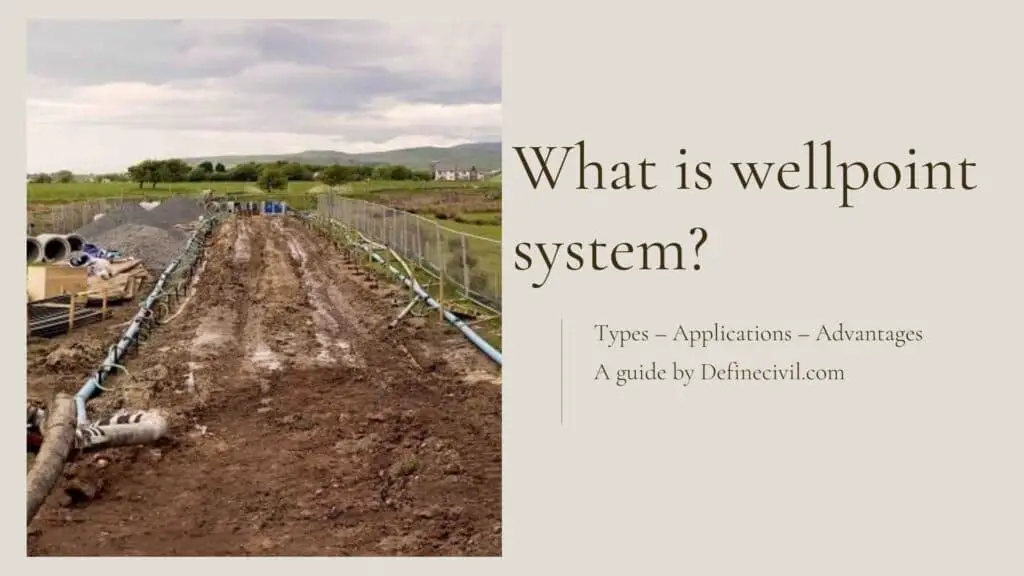

While undertaking deep excavations for construction of foundations, engineers face difficulties in terms of expulsion of subsoil water. That’s where a wellpoint system serves as the best dewatering tool for lowering the water table below excavation levels.

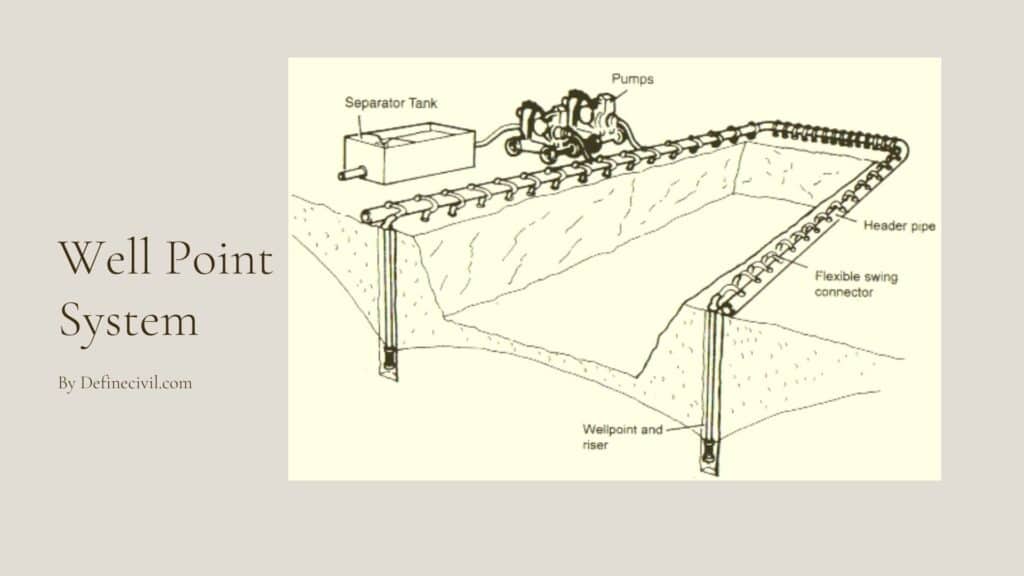

A wellpoint dewatering system consists of a series of shallow wells, known as wellpoints. We install these wellpoints at a pre-determined depth and appropriate spacing around an excavation.

Wellpoint dewatering system has proved a versatile and effective technique for dewatering low flows from silty sands and high flows from coarser sands and gravels. For shallow trenches, around 50 to 70 wellpoints are enough.

So, what is a wellpoint system?

In this technique, the engineers establish a wellpoint dewatering system around the perimeter of the project site against excavation shoring and supports. Afterwards, we establish a discharge line around the perimeter using connected series of pump sets.

A wellpoint is essentially a pipe that has an opening diameter such that it avoids movement of the water bearing formations but at the same time allows water to enter. Typical wellpoint opening is around 38-50mm in diameter.

[su_service title=”Also Read” icon=”icon: pencil” icon_color=”#227f24″]Hydrovac Excavation – A new technique for underground excavation[/su_service]

Parts that make up a wellpoint are as follows; a pump that extracts water, a riser pipe connecting it to the surface, a shaft and a well that gets filled up. The riser pipe has openings at the bottom that allows the water to be extracted to the surface and the sizes of these openings are determined by the grain size of the material used for the formation.

What is a well point?

There is a large variety of wellpoint designs such as PVC well points, which are usually found in irrigation and residential water systems, and PVC well screens which are commonly used in ponds, irrigation wells and ponds, whether natural or artificial.

A wellpoint is usually more efficient in terms of time and cost as compared to a borehole especially is scenarios where the desire is of a shallower depth. However, it cannot be used for retrieving large quantities of water, typically around 5gal/min can be extracted and the general height limit is of 5-6m for the extraction of water. For the requirement of greater depths, another set of well points can be installed at a lower level.

What is a wellpoint system?

A wellpoint system is basically an array of small diameter shallow wells connected to a pump, usually installed by; water jetting or rotary drills. The header main pipe is connected to the system and a dewatering pump of high efficiency is used to pump water with vacuum technology.

Such systems are mostly used to provide stable working conditions by lowering the level of the groundwater table in excavation sites. The main areas where this system is suitable are utilities for de-watering, trench works and shallow foundations.

[su_service title=”Also Read” icon=”icon: pencil” icon_color=”#227f24″]Use of bentonite slurry in Pile foundation – A thorough article – Click Here[/su_service]

Why dewatering is necessary during excavation?

In most underground excavations, groundwater conditions are critical. Without properly handling such groundwater conditions, the projects will delay causing loss of money. That’s where we employ dewatering operation using wellpoint system.

Keeping in view the site requirements, we use pump sets at sufficient distances. But you must make sure the ground water stratum is permeable. Otherwise, we can’t draw groundwater with wellpoint system.

Types of Wellpoint systems

The different types of wellpoint systems are as follows:

· Single-Stage wellpoint systems

This type of well system consists of a pipe of dia 50mm and a length of 1m with a screen covering the perforations in order to prevent clogging the pipe. At the lower end, a component called a jetting nozzle is provided which also acts as a derive point or a well point. A ball valve is included in the lower end during the process of installation that prevents the water to flow in the other direction. A riser pipe of the same dia as the wellpoint is connected at the bottom end and at the ground level, the horizontal or header pipe are connected to the riser pipes. The horizontal pipe is further connected to the pumping unit.

During the installation process of the well point, water is gushed downwards at the required depth and the installed pump is used to regulate the required water level till excavation is complete. These systems are used when the depth of excavation is less than 4.5m and are exceptionally effective in granular soils.

[su_service title=”Also Read” icon=”icon: pencil” icon_color=”#227f24″]Top down construction technique – An interesting article – Click Here[/su_service]

· Multi-Stage wellpoint systems

Places where the depth of excavation required is more than 4.5m or the slope is susceptible to failure, a multistage wellpoint system, with the well points are installed in stages, is recommended.

The wellpoint is positioned at a depth of 4.5m at the first stage and the water level is lowered by that much. The surrounding area is then excavated, and another wellpoint is installed at a further depth of 4.5m. The process is then repeated till the requirement is met. But this system has a limit of 15m after which excavations cannot be made.

Installation of a wellpoint system

For the installation of a placing tubes used with disposable points and self-jetting well point, high pressure jetting pumps are used. The water supply rate and pressure of the most commonly used jetting pump, supplying water with the aid of a jetting hose, is 20 L/s and 6-8 bars respectively. Standard fire hoses with male and female connectors are used for jetting hoses.

For heavy duty uses such as pile jetting, hoses and jetting pumps with higher power are often used. For all types of well points and installation techniques, a constant supply of clean water is essential. If the strata consists of compacted soil or gravel, the process of jetting can be tedious.

The system and its installation is extremely flexible in the sense that if after the first installation, there are some trouble areas that require more well points, they can be added quickly. This fact is very useful for excavation of shallower depths where the estimated period of pumping is short.

Here’s a diagram of wellpoint system for that explains the working principle:

Applications of Wellpoint System

- A typical application of wellpoint system is temporary dewatering. We lower the water level in the ground during construction and engineering works.

- We use it to establish drainage systems for building trenches/excavations.

- Lowering ground water level for general purpose like subways construction

- Dewatering or lowering ground water to stabilize land and reduce slips / failures.

- Dewatering for agriculture purpose

- To obtain water for house, garden, or other irrigation purpose.

- Laying of deep sewer lines

- Tunnel Excavation or subway construction

- Hydro projects or canals

- Water distribution system projects

- Construction of bridges and basements

- Underground water tank construction

[su_service title=”Also Read” icon=”icon: pencil” icon_color=”#227f24″]Difference between compaction and consolidation – An interesting article – Click Here[/su_service]

Advantages

Quick installation

In comparison to some large dewatering systems, wellpoint system can be deployed quickly. This not only helps you in reducing the downtime of the project but also helps speeding things up. You can use this method in most ground conditions.

Easy maintenance

In case of some issue or problem, the system can be easily maintained without the need of any sophisticated tools.

Versatility for both small and large scale projects

Because of affordability, we can use wellpoint system for dewatering in both small and large scale projects. You can use the same equipment, no matter the scale of the project. We can design and deploy the system for draining fine-grained soils that otherwise won’t give water easily.

Can be used even in limited space projects

Even if the space is limited around the project, you can use self-jetting wellpoints to cope up with the requirement.

Cost-effective

It is a cost-effective technique even for small-scale projects. It works best for many types of soil even in stratified soils.

More effective than deep well dewatering system

This is the most efficient method as it covers a large area of land than other systems like deep well dewatering system. This method is capable to work consistently at 100 m3/h capacity of water. It is also discharged airflow with head up to 60 ft.

Disadvantages

- This system is more efficient in sands and gravels than in fine-grained soils. A suction lift of 5 to 6m in sands and gravels can be achieved but this may be limited to 3.5 to 4.5m in fine-grained soils.

- While using header main you can face problems at sites in terms of access restrictions.

Wait it’s not over yet, I have a gift for you.

Wellpoint system pdf

Here’s a pdf version of wellpoint system infographic that you can save on your cell phone and computers for future reference:

Download the infographics by clicking the button below:

[su_button url=”https://definecivil.com/wp-content/uploads/2021/08/well-point-system.pdf” target=”blank” style=”3d” background=”#1cae1b” size=”5″ center=”yes” icon=”icon: comment” text_shadow=”0px 0px 0px #000000″]Download the infographics[/su_button]