For most of the cements we use in construction has a specific gravity of cement ranging between 3.1 to 3.16 g/cc and a density of 1440 Kg/m3. But that doesn’t mean it stays same for all types of cement we have.

Moreover, specific gravity itself is an important quality control parameter for cements while determining mix design of concrete.

You’ll understand why it is important, after reading the article.

So, let’s start with the basics.

Definition of Specific Gravity of Cement

The weight of a particular volume of cement, compared to the weight of the very same amount of water at a given temperature is how we define specific gravity of cement. The definition of specific gravity is similar in general for all substances.

We can also say specific gravity as the relative density.

But as a civil engineer, you might be wondering why we actually need to determine specific gravity of cement.

Well, you already know that specific gravity of a substance is a number used to determine whether an item will float or sink in water. Every substance has a specific gravity. Typically, the figure is in numbers ranging from 0.1 to 100.

The substance will glide on water if somehow the number is lower than one. The substance will submerge if the figure is higher than 1.

Meanwhile, for cement, specific gravity lies at the figure representation of 3.15 g/cc that indicates that the cement is 3.15 times heavier than the same volume of a reference substance (water).

Significance of the test

For most of the concretes we design, has a cement of specific gravity 3.15. But if the same cement is exposed to extreme moisture condition (humid weather), the value would change.

The moisture content in the cement would increase or decrease the value. The fine cement particle can absorb moisture content into the pores. With such, the value of specific gravity would differ from what we were actually expecting.

What do you think is the reason of avoiding old-stock cement from using? Well, that’s because the cement pores and particles can absorb water content from the atmosphere. This would entirely change the mix design characteristics. As a result, the quality of concrete would not be that good.

Same stands true for poorly manufactured cement. During manufacturing, the manufacturer may not properly mince cement clinker into fine particles or may be the cement has high moisture content. We need to make sure not to use such low quality cements in our concretes.

You can also identify such issues, by observing lumps or chunks in the cement sample.

So we can conclude as:

- Small porous openings or minute particles in the cement grains allow water to pass through.

- A standard mix is made using 3.15 g/cc of cement’s specific gravity. A certain modification in the dry density factor of cement will have an impact on the mixture design.

- Therefore, if the cement is introduced to high levels of humidity owing to unfavorable weather, the specific gravity of the cement might rise to 3.19 g/cc.

- As a result, before beginning the mixing phase the cement’s specific gravity must be determined through a test.

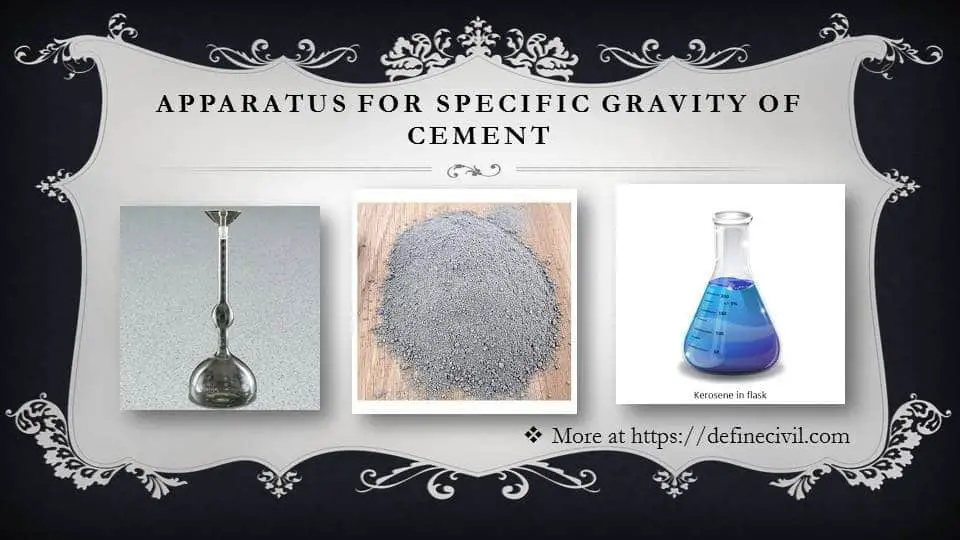

Test for Specific Gravity of Cement

We can determine specific gravity of cement in laboratory with a simple test. We use Le Chaterlier’s flask and Karosene to have a ratio of weight of cement solid particles. We’ll use Karosene to determine the volume of solid cement particles indirectly.

Just correlate this test with how indirectly you determine the volume of soil in fdt by sand cone method.

Apparatus

Here’s the apparatus you need for this test:

- Le Chaterlier’s Flask

- Weighing Balance

- Kerosene should be free from water

- weighing balance

Le Chaterlier’s flask is actually a thin glass apparatus having a bulb of 7.8 cm in diameter at the bottom. This bulb is of capacity 250 ml.

Standard

We follow Le Chatelier’s Principle. For such, Specific gravity of cement is determined by Le Chatelier’s Flask method. And the IS code for Specific gravity test is IS 2720- Part 3.

Procedure

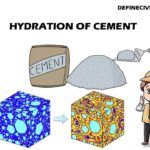

In most cases, water is employed to determine the specific gravity of a substance, although, in the case of cement, kerosene is used. The rationale behind this is because whenever cement interacts with moisture, it hydrates and creates calcium oxide. However, when cement is combined with kerosene, it does not react. The specific gravity of kerosene is 0.79 g/cc and that of water is recorded to be 1.00 g/cc.

- First dry clean the Le Chaterlier’s flask and make sure no moisture stays inside the flask.

- Now fill it with naphtha or kerosene to a level on the stem around zero and one ml. (You can take note of readings from graduated cylinder)

- Note the volume of liquid inside the flask as V1 in ml.

- Now, fill the flask with a weighted amount of cement (approximately 50 gm) until the kerosene content reaches nearly 22 ml, taking caution not to splatter and to ensure that the cement somehow doesn’t attach to the edges of the flask just above the content of the liquid.

- After you’ve added all of the cement inside the flask, agitate it carefully at an inclined angle to release air till no more air bubbles arise on the liquid’s surface. Take this level of liquid as final measurement V2 in ml.

- The flask must be kept at a consistent temperature while taking each measurement to acquire a more precise outcome.

Observation and Calculations

Here’s how we can make lab report for specific gravity test of cement in pdf

- Weight of cement poured inside the flask = W grams

- initial reading of the flask = V1 ml

- Second reading of the flask = V2 ml

- Volume of cement particles = V2 – V1 ml

- Weight of equal of water = (V2 – V1) x specific weight of water

Hence, formula for specific gravity of cement is :

Specific gravity of cement = (weight of cement / weight of equal volume of water) = W / (V2-V1)

Recommended Values

The density of Portland cement ranges from 3.10 to 3.25 Mg/m³, with average 3.15 Mg/m³. For proportioning in mix design, it may be more useful to express the density as relative density (specific gravity). On an average the specific gravity of cement is 3.15

Conclusion:

It is really important to know the specific gravity of cement before using it for construction purposes. The main reason is that specific gravity works out through the phase of water in the form of moisture, air, and solid substance which is already present in the provided volume of the soil where the construction is supposed to take place. S

Some of the cement material came forward to be of either high or low-level specific gravity bearers, which might impact the durability of the structure of the building. Therefore, it is really important to know beforehand the exact level of specific gravity of cement.