Civil Engineers deal with different types of slabs for roofing, and flooring. Some of these slabs are precast and some are cast in-situ. But how do you explain slab?

A slab is a planar and flat structural element of a building that act as a floor or ceiling resting directly on columns or beam in frame structure. It act as a covering for a building that provide flat useful area and protect occupants from elements like rain or snow.

So, how do you choose between different types of slabs?

In construction different types of slabs are used like one-way or two-way slab, flat slab, monolithic slab or monoslab, slab at grade, composite slab, waffle slab, hollow-core slab, pre-stressed slab.

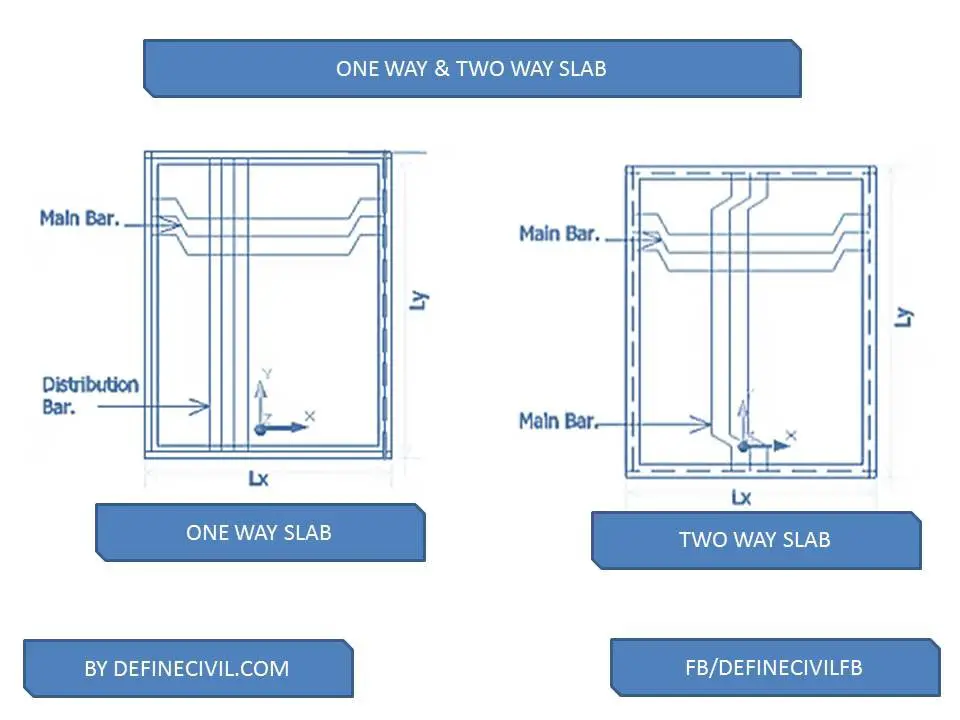

Two of the most common concrete slabs are one way and two way slabs depending on the ratio of slab dimensions (width & length). You can decide the type of type of slab depending on the purpose, span, loading condition, and application of structure.

What is slab in construction?

But what slab means in construction?

A slab is a 2d structural component of a building that is flat, generally thinner than the planar area, and can be reinforced or plain (un-reinforced). Reinforced concrete slabs are used in buildings as roofs, floors, ceiling or as deck of bridges.

Example of slabs – Uses

Some uses examples of a slab:

- Sidewalks to provide flat surface for pedestrians to walk along the road.

- Driveway – a flat concrete driveway slab provides smooth surface for vehciles to enter or exit a property.

- Roadway slab – An un-reinforced or reinforced concrete slab to allow traffic movement across an area.

- Reinforced concrete roof slab – A flat slab act as a roof or ceiling for a building

- Use as a bridge deck.

It takes area loading from structural point of view as load is distributed across the entire area.

The slab (ceiling or flooring) transfer the area load to the supporting beams, columns, walls or the ground. Besides, it provides a flat useful surface for the occupants of the structure or a building.

Anyhow, slabs in construction can either be of reinforced concrete or unreinforced concrete.

The need of reinforcement depends on the design requirements and loading conditions.

Reinforced concrete slabs are further classified depending on the type of supports as well as the ratio of slab spans.

Applications and Uses of Concrete Slabs

Here’re some common uses of concrete slabs:

- Concrete slabs provide a flat and horizontal surface for residential and commercial buildings.

- Concrete slabs one above the other, act as a ceiling or roof that provides protection to the occupants from outside elements.

- In parking lots or multistory buildings, inclined concrete slabs are provided as a ramp to let vehicles enter or exit.

- Lean and thin slabs are used for exterior paving. These slabs are called mud slabs.

- Some concrete contractors provide leaner slabs as a patio along the premises of a house.

- Medium-sized precast concrete slabs find application as false flooring for modern facilities.

- Experts recommend concrete slabs as pool decks. You can have your slab printed, stained or even textured to match the design and appearance of your exterior building.

What are the types of concrete slabs?

Following are the main types of Slabs we discuss in detail ahead:

- One Way Slab

- Two Way Slab

- Unreinforced Slab

- Ground Bearing Slab

- Suspended Slab

- Mud Slab

- Flat Slab

- Hollow Core Ribbed Slab

- Hardy Slab

- Waffle Slab

- Dome Slab

- Post-Tension Slab

- Roof Slab

1. One Way Slab

This classification of slab is based on the ratio of spans and the sides of support. A one way slab is supported on two sides only with ratio of long to shorter span as smaller than or equal to two. In this type of slab, the bending is along the shorter span i.e. only in one direction. Main rebar is along the shorter span while distribution rebar is along the longer span.

One way slab can be two types:

- One way slab supported on beams at two ends

- One way slab with joists (ribs) – called ribbed slab

In most of the buildings, we provide cast in-situ one way slab to support on edge beams. In-situ method includes fixing of formwork, installation of reinforcement, and pouring of concrete. It is an cheap slab for smaller spans of 3 to 6 meter. It is ideal for loads of 3 to 5 KN/m2.

For spans greater than 6 meters, experts recommend one-way joist slab. It is a ribbed slab that have tapered ribs equally spaced at distance lesser than 750 mm. These ribs are supported on girder that further rests on columns. You may need lesser amount of reinforcement for this slab but at the same time, expensive formwork is required.

2. Two Way Slabs

Two way slab is commonly used in framework structure. Unlike one way slab, it has support on all the four sides and it bends in a bowl of shape.

Anyhow, it is ideal for areas where you need span of 6 to 9 meters and live load is 3 to 6 kN/m2. Because of more support on sides, it has lesser deflection and has more stiffness.

But you need to provide more reinforcement and the formwork required would be more.

For a two way slab, the ratio of longer-span to shorter-span is less than 2. The load is carried in both directions.

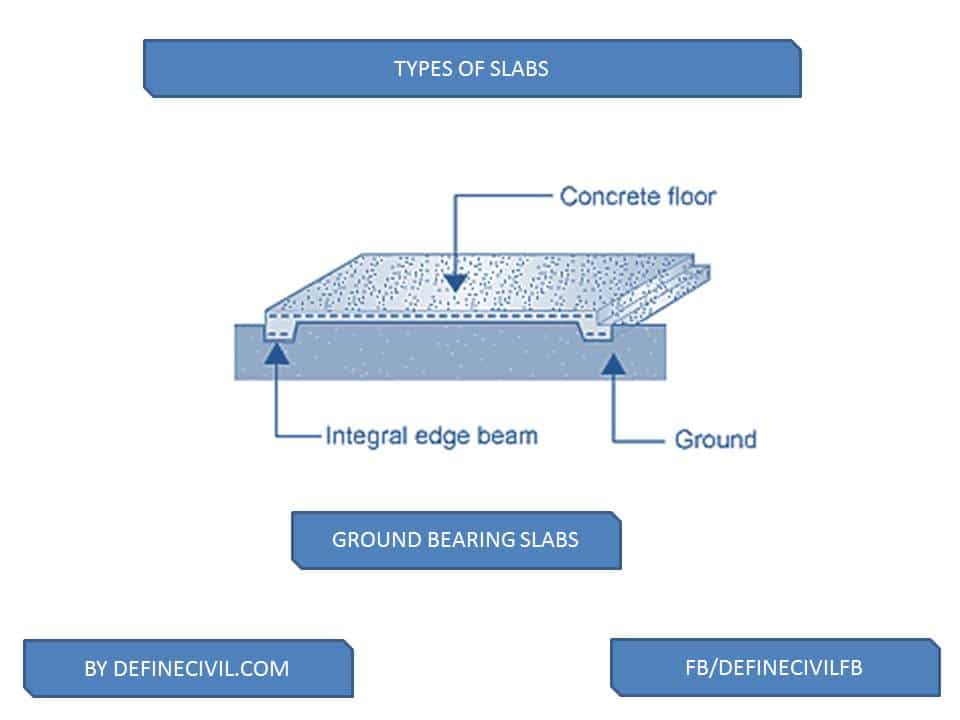

3. Ground Bearing Slab

As the name suggests, it is the simplest type of concrete Slab that is mainly touching the ground. We also name it as “on-ground” and “slab-on-grade”. It typically has a square mesh of reinforcement at the bottom of the slab with 50 mm cover. But reinforcement is not always necessary. For areas with good subgrade support, reinforcement can be omitted.

Ground bearing slab is used in areas

- Where the ground is flat and little slope exists

- The subgrade is stable and fire.

- Subgrade soil is gravely and non-clayey or non-expansive.

- The load is static and more specifically uniform.

Ground bearing slab is cheap and useful for ground floors of residential and commercial buildings. The thickness of the slab is more than 100mm. But the thickness of slab depends on the type of loading and the soil bearing capacity. To avoid shrinkage cracks, we provide construction and contraction joints at 6 meter intervals least.

If you opt to use unreinforced slab, be sure to provide apt curing after casting. The curing would allow good hydration reaction and avoid shrinkage cracks during the process.

4. Suspended Slab

Suspended slab is opposite of what we know in ground bearing slabs.

Suspended concrete slabs are:

- Not in contact with the ground or earth

- are above-ground level

- Are like floors or roofs of a structure.

- Span a space of 3 to 6 meters

Suspended slabs act like a cantilever. They span a distance and provide unobstructed passage like a roof. These slabs “MUST” have reinforcement for safety. But despite that, you need to ensure thickness of 100 to 500 mm. But, the thickness depends on the type of loading, number of supports, and the span length.

One of the most crucial aspects in construction of suspended slab is formwork and scaffolding.

Two of the most common type of suspended slabs are:

- one way slab

- two way slab

5. Unreinforced Slab

As the name suggests, unreinforced slab doesn’t have reinforcement against bending. That’s why it is the cheapest of all other types of concrete slabs. In some cases only shrinkage or temperature reinforcement is provided. They are mostly at-grade slabs.

We found applications of these slabs in:

- Airfield taxiways

- Airfield aprons

- Yards and decks

- Concrete pavements and highways

- Screeding for floors

- Concrete floors

Reinforced concrete slabs gives savvy answers for a large number of circumstances. Anyhow, you need to make sure the service loading (static or dynamic) stats well within the limits of concrete’s flexural strength.

6. Mud Slab

Mud Slab is a low-quality thin layer of concrete. In most common cases, it is only 2 to 6 inches thick, poured underneath the primary Slab yet over a layer of wet or sloppy soil. It can fill in as the surface for the waterproofing layer is applied.

Mud slabs has uses in subfloors, crawlspaces, pathways, paving, and leveling surfaces. We mostly use them when we need clean and flat surface. Mud slabs are like blinding or lean concrete where you need a flat surface to fix reinforcement.

Recently, some manufacturers are providing, precast concrete slab panels or bricks. They are placed on a yard above a well-compacted ground. These slabs prevent muddy conditions in your courtyards.

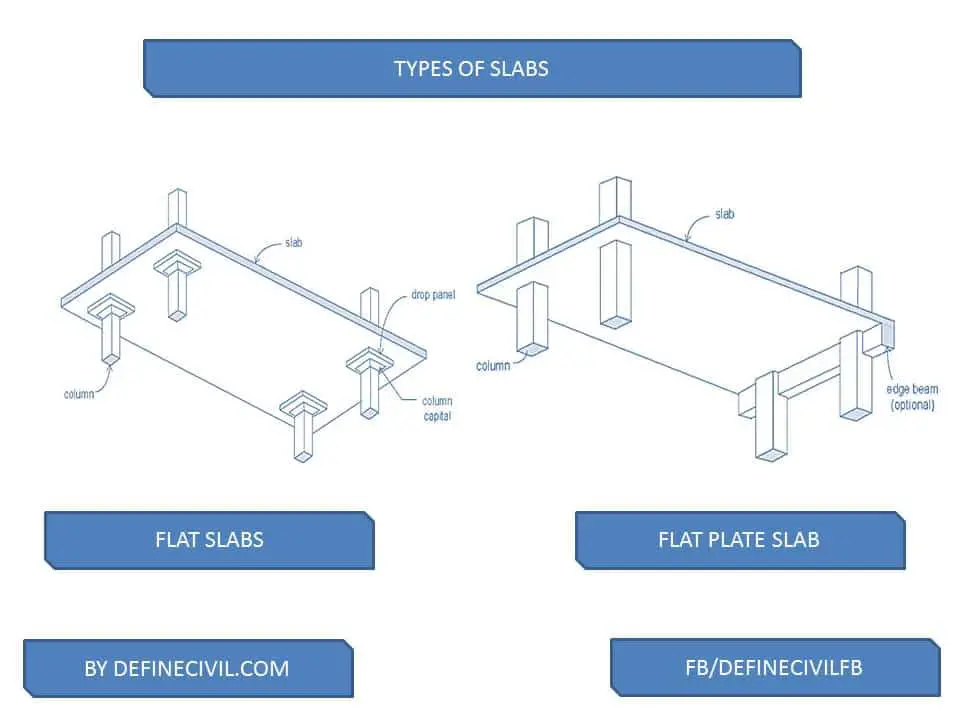

7. Flat Slab and flat plate slab

A reinforced concrete slab that rests directly over columns is known as a flat slab. You won’t need a beam or extra support. In most of the cases, only extra reinforcement is provided at the zones near columns to avoid punching shear. Another type of similar slab is a flat plate slab.

In flat plate slab, there’s no column capital or drop panel. A column capital is flaring up of the columns at their joint with the slab. This provides extra supporting area at the periphery of the column. In case of drop panel, a thickened part of slab is provided at few meters along the periphery of the column.

If you have a span of less than 8 meters and live load is less than 5 kN/m2, you can go with a flat slab without any column capital or drop panel. But in other cases, you may have to use flat slab with column capital or drop panel.

A flat slab is cheap and fast to construct. But it has low stiffness, and you can see deflection even with naked eyes.

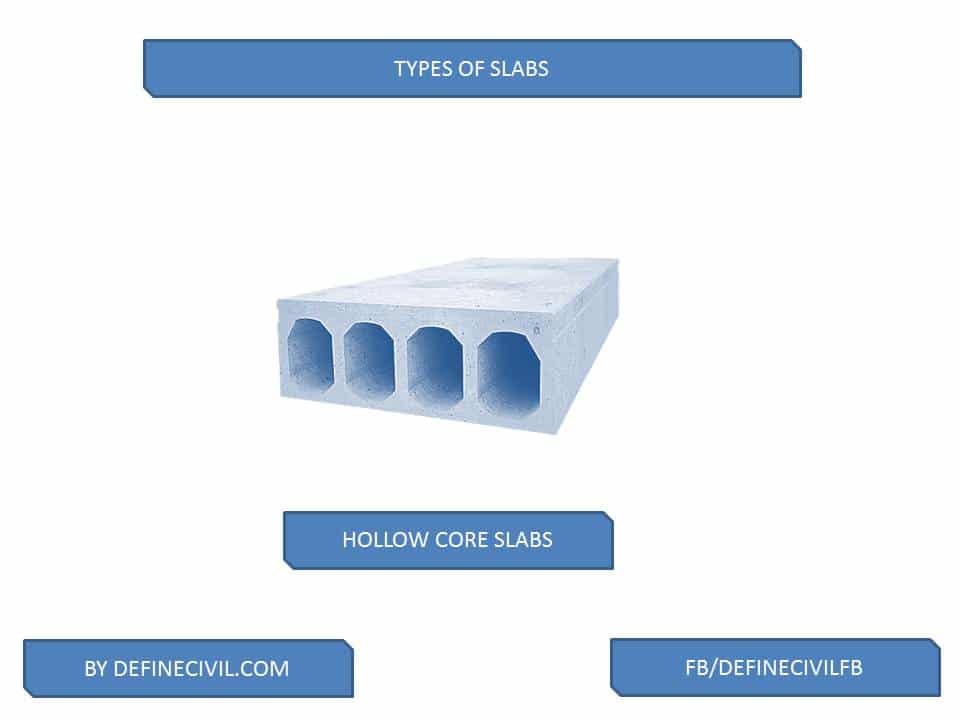

8. Hollow Core Slab

If you need fast construction and are looking for a cheap and structurally-efficient slab, hollow core slab has a lot to offer.

Hollow core slab is a precast type of slabs that has hollow cores in their depth. They are light in weight and are can take depth of 110 to 400 mm. In case of precast units, one unit is 1.2 meters wide that are joined together with keys.

The slab has an enhanced qualities of fire-resistance, sound-proofing, and heat insulation. It is a cost-effective solution for modular construction. You can use hollow core slabs for parking garage decks and roof structures. Other uses are floor structures, warehouse, office building, schools, and airport terminals.

Hollow core slabs sometimes are pre-stressed to enhance their efficiency during serviceability.

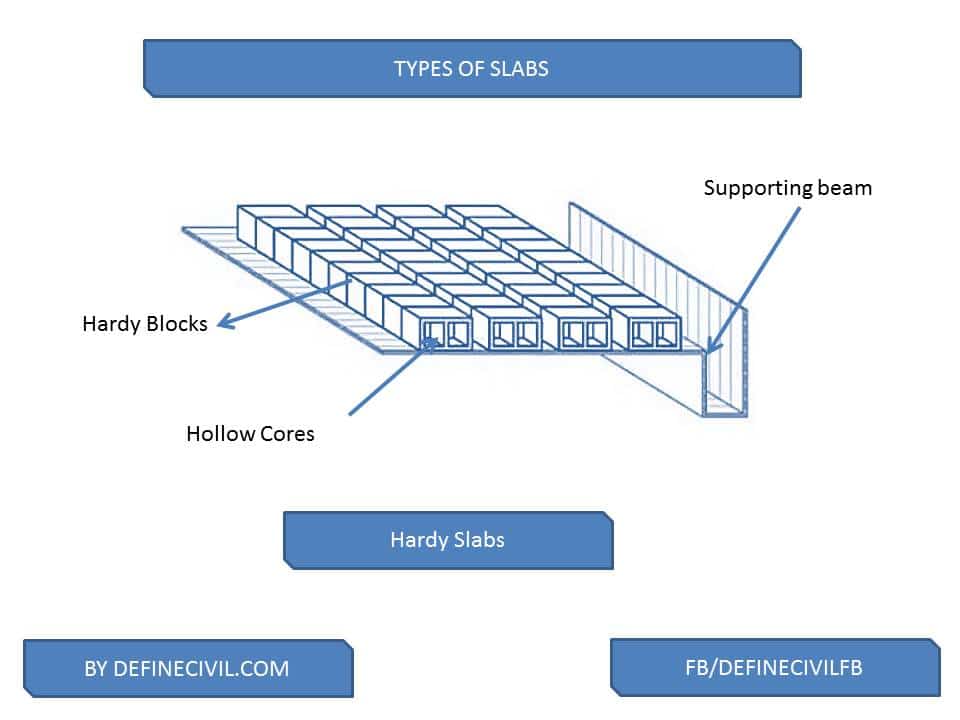

9. Hardy Slabs

Hard slabs are generally used in areas of high temperature like in Dubai, UAE, and other gulf countries. The name derives from the use of hardy bricks in the core of the slab.

During construction, we place hardy hollow bricks in the concrete slab below neutral axis. We provide reinforcement between the hardy core blocks. This considerably reduces the quantity of concrete required for the slab.

Though you need to increase the thickness of the slab, but cost-efficiency is at higher-end. Hardy slab roofs tend to be lighter and are very efficient for insulation. The hollow portions of the hardy bricks do the trick of providing air between two layers of concrete slab.

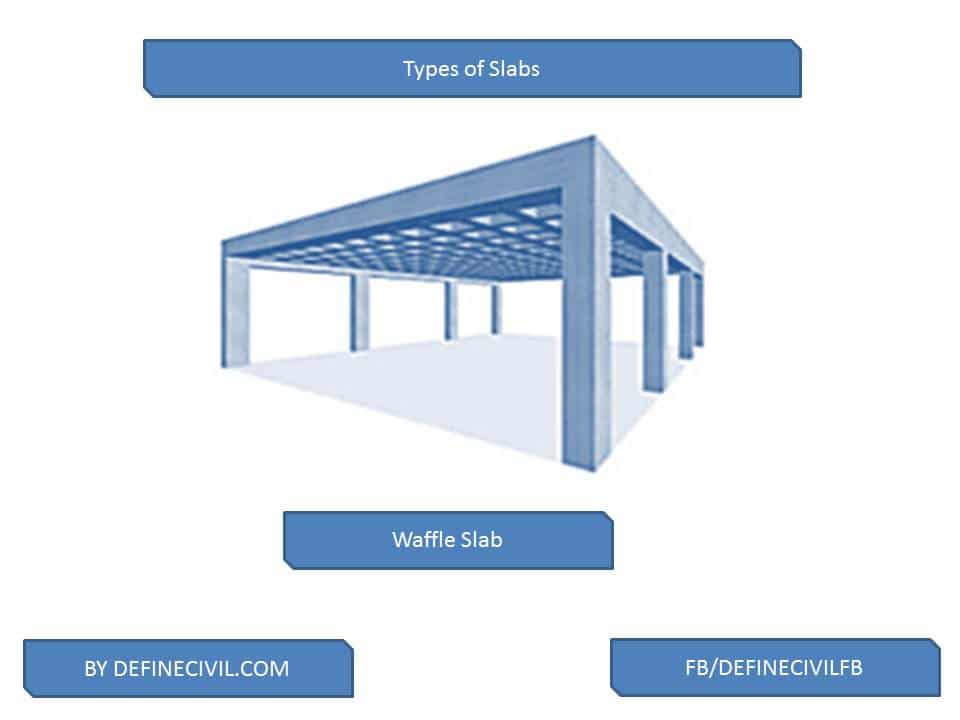

10. Waffle Slab

It is one of the most useful slabs to achieve long and unobstructed spans. We found its application in auditoriums and cinema halls. To avoid supports or columns, we provide thick supporting beams at uniform distance in both the directions like a grid.

This grid of supporting beams forms a hollow part between. You can provide artificial lighting for enhanced view like in restaurants, hotels, and shopping malls.

Thickness of slab

The thickness of depends on different factors like load, type of slab, and size of the building. For typical residential building 6″ thick reinforced concrete slab is perfect. You can design the reinforcement to satisfy the bending moment and loading conditions. The typical thickness of slab varies from 4 to 6 inches.

Here’re how you calculate slab thickness using span (clear span)

- Simply supported Slab = Span/20

- One end continuous Slab = Span/24

- Both End continuous slab = Span/28

- Cantilever = Span/10

Some building codes specify the minimum thickness of floor slab as 3 1/2 inches (89mm). As per IS 456-2000; the minimum thickness of slab is 125 mm.

Opening in Concrete slab

Openings of cutouts are sometimes required in concrete slab for HVAC ducts, pipes, stairs, elevators, or plumbing. But as these openings can decrease the member stiffness so additional opening reinforcement in diagonal direction are provided to prevent cracking from structural loads of shrinkage. These opening in concrete slab are common in commercial buildings.

Apron Slab

So, What is an apron slab?

An apron slab or concrete apron is a smooth path made of un-reinforced concrete at the entrance of parking lot, along the front of a garage, or around the perimeter of a building.

In case of residential buildings, the apron slab is the first 2 to 6 feet of concrete between the garage floor and the driveway as a ramp. This apron area is sometimes covered with asphalt.

Sometime an apron slab is used to prevent spillage of water from soaking into the ground or at the opening of a culvert just on the water channel to reduce erosion and improve capacity. That is called an apron slab for water points.

In cases of apron slab in culvert, we can also place grouted rip-rap as a cost-effective mean to protect structure from scour and storm damage. This treatment is carried out both on the inlet and outlet of a culvert.

Suspended Slab

A suspended slab is the slab of upper floors that is not resting directly on the ground but instead rests on the loadbearing walls. The other ground-bearing slab is the one that rests directly on the ground acting as a floor or apron. Suspended slabs act as a floor for upper stories and ceiling for the lower story in houses. A suspended slab requires significant support system in terms of scaffolding and formwork.