Chain surveying is a very common method of surveying that is used for less-precise but quick results. It is the simplest of all other methods of surveying like traversing, topography, or plane table surveying.

Chain surveying is a very old method but is still used at times when you don’t have proper equipment and technologies like in remote areas.

Unlike other methods of surveying, in this method only linear measurements are noted and no angular measurements are taken. Surveyors use it to find lengths and features of small areas that are mostly plane and not many details are there to show.

Only natural or man-made features are displayed that are near or around the area of interest.

What is chain surveying?

In chain surveying, surveyors use chains of different types and lengths to measure and record series of linear distances on ground. In India and Pakistan, we use to perform land measurements using link type surveying chains of 30 meters length.

Pros and cons of chain surveying

Anyhow, with the use of chain surveying, there come many pros and cons. A surveyor needs to look into such aspects before finalizing the method of surveying. However, chains are very robust and are portal. Apart from its hefty weight, there’re not much issues for taking it to the site. You can easily take readings. If your chain has some issue, you can readily repair it in the field without need of an expert.

But overtime, these chain links do wear. Being a metal surface, they can bend and mud can take space inside bearing surface.

Principles of Chain Surveying

With the help of chains, surveyors take length of straight lines that define the skeleton or framework in an area. You can plot such a framework of lines on a blank paper according to a suitable scale.

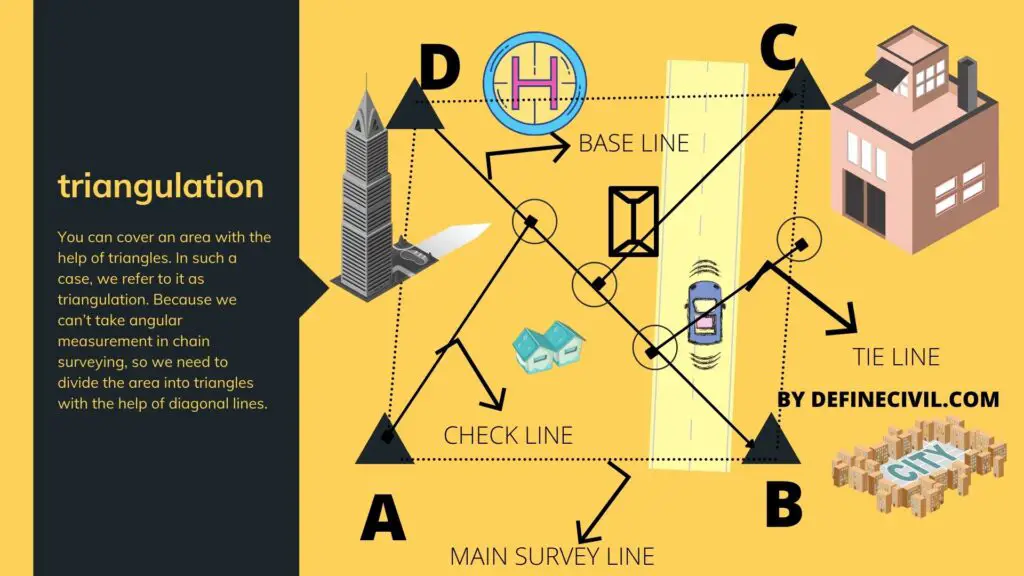

The main principle of chain surveying is triangulation.

You can cover an area with the help of triangles.

In such a case, we refer to it as triangulation. Because we can’t take angular measurement in chain surveying, so we need to divide the area into triangles with the help of diagonal lines.

The triangles must be in such a shape that the angles are between 30 or 120 degrees. You can’t take a triangle less than 30 degrees or more than 120 degrees. Surveyor prefers to use equilateral triangles, because it is easy to resolve.

For example let us take an example of an area with points ABCD. Now, we can’t plot these points unless we know the angles between lines, say AD and AB. so, the only way forward is to divide this area into triangles by drawing diagonals. So, that if you measure linear distances like AB, BC, CD, DA, and BD; you can easily plot these point on a piece of paper.

Suitability of Chain Surveying

Chain surveying is not suitable for a very large or uneven area with a lot of details to cover. It is mostly suitable for a relatively smaller area that is leveled. You can only cover flat area that has less number of details to cover. It is only possible to survey open area that doesn’t have many obstacles.

Common Terms in Chain Surveying

Here’re some common concepts that I believe will be handy for you in the field.

Main Stations

The stations that are at the end of the main survey lines that form the skeletal system are known as the main stations. These stations are the boundary of the surveying area. Main stations shall be selected in open area and as low as possible.

Tie or subsidiary stations

On the main survey lines, some intermediate stations are specified to determine interior details; such stations are called tie or subsidiary stations. You can use these stations to show interior details including fences and hedges.

Base lines

Base line is a diagonal longest line that runs from the center of the field. As the name suggests, it is the main line that we use for taking measurements of all detailing work.

Chain lines

The survey line joining the main survey stations is called the chain lines. These chain lines join any two of the main stations.

Tie Lines

Tie lines are subsidiary lines that run between two subsidiary or tie stations. These lines are usually used to cover extra details between the main survey line and base lines.

Check Lines

As the name indicates, check lines are used to check the accuracy of the main survey framework. Surveyors measure the length of the check line in the field and compare it with the length on the plan. Both must be equal for the survey to be accurate.

Offsets

The word offset refer to the lateral measurement taken from the baseline or base survey stations. The purpose of the offsets in chain surveying is to locate the boundary lines of various objects near the base line. Surveyors typically use two different types of offset in chain surveying keeping in view the ease of reach.

Perpendicular offsets: These offset lines are at right angle with the main chain line.

Oblique offsets: These offset lines or ties are at an angle with that of the chain line. Surveyors only prefer such type of offsets when an established tie station is available and the building or the feature to record is not in straight with that.

Types of Chains used in surveying

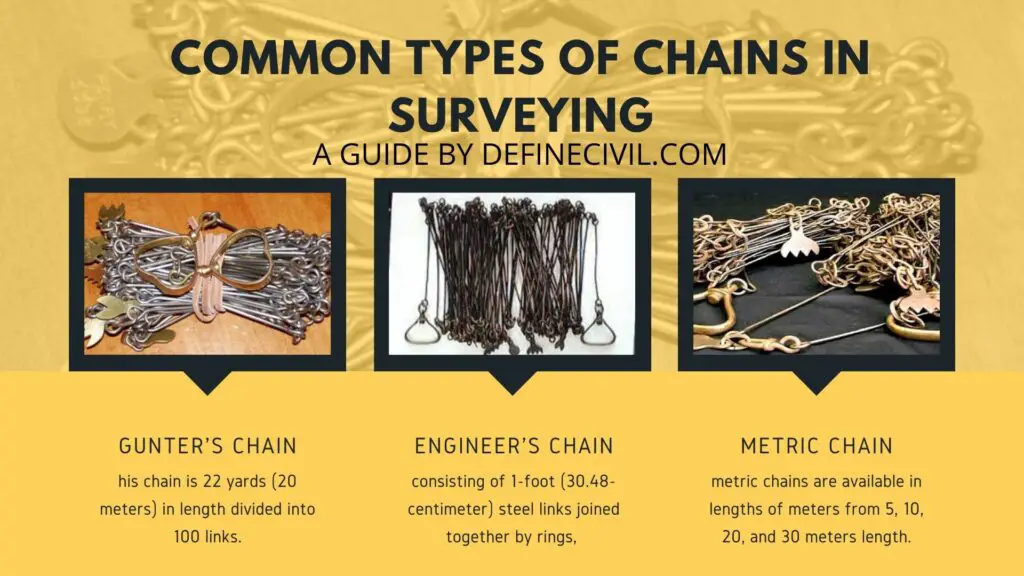

Different parts of the world and different pioneers used to adopt different types of chains in the field. These types vary on the basis of length, material, or unit of division in the chains. Following are the common types of chains used in chain surveying:

Metric Chains

As the name suggests, metric chains are available in lengths of meters from 5, 10, 20, and 30 meters length. Metric chains are well-covered in IS code 1492-1970. Tallies or marks are fixed at intervals to make it easier for the surveyor to take record of readings while in the field.

For the chain length of 5 and 10 meters, tallies are fixed at every one meter interval while for chains of length 20 and 30 meters, the same is available after every 5 meters. For 20 and 30 meters length chain, small brass rings are fixed at every one meter length for accurate readings.

Steel Band or Band Chain

Apart from the drawback of bending of the links, steel band or band chain is commonly used chain. It consists of a steel band of width 12 to 16 mm having thickness of about 0.3 to 0.6 mm.

Gunter ’s chain or Surveyor’s Chain

It’s another quite popular type of chain. It is referred to as Gunter’s chain or surveyors chain. The chain is named after an English mathematician Edmund Gunter. This chain is 22 yards (20 meters) in length divided into 100 links.

Engineer’s Chain

An Engineer’s chain measuring instrument consisting of 1-foot (30.48-centimeter) steel links joined together by rings, 100 feet (30.5 meters) or 50 feet (15.25 meters) long. This is also known as a chain.

Revenue Chain

Revenue chain is a standard 33 feet long chain with 16 links joined together with each link being 2 feet in length. This type of chain is mostly used for cadastral surveys.

Here’s a brief review of different types of chains:

| Chain Name | Length | Links |

| Metric Chain | 20 m

30 m |

100

150 |

| Gunter’s Chain | 66 feet | 100 |

| Engineer’s Chain | 100 feet | 100 |

| Revenue Chain | 33 feet | 16 |

Procedure of Chain Surveying

Here’s how you perform chain surveying in the field.

- First you need to perform reconnaissance of the area. It involves the preliminary inspection of the area and preparation of the rough sketch or index map.

- Now the area is divided into triangles, called triangulation.

- After you have planned and identified the survey stations, you can now fix them in the field. You can either drive pegs or fix ranging rods if the area is soft ground. For hard surface you can fix stones or color them.

- The next step is to mark and measure the survey station distances in the field and initiates the chaining.