You might have heard the concept of flitch or flitched beam during a historic renovation project and are now wondering, what is a flitch beam? its purpose and benefits.

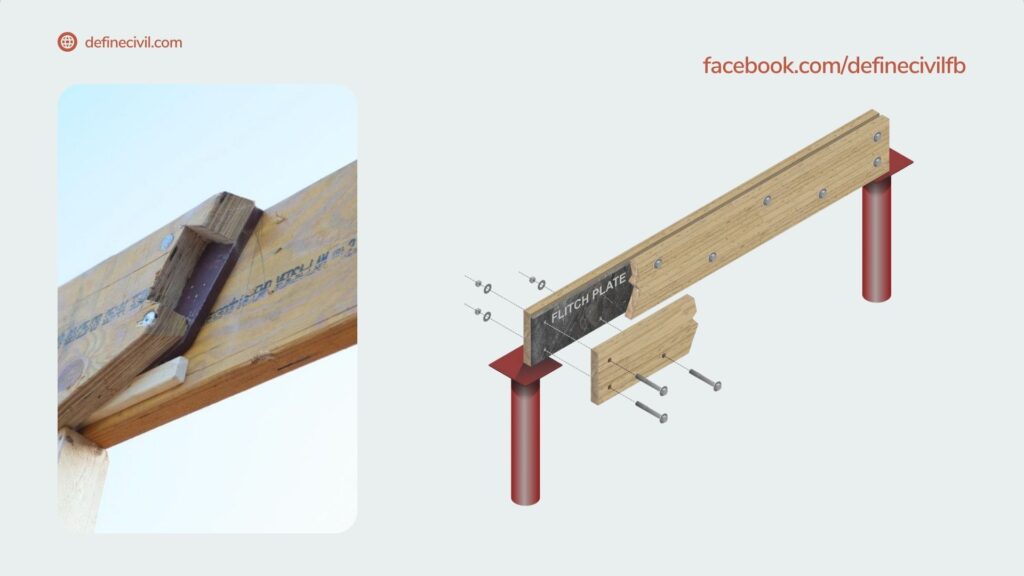

A flitch beam, also referred to as flitched beam is a composite beam that uses vertical steel plates as reinforcement for wooden beams. These steel plates are called flitch plates and hence the name flitched beam. There’re three layers of a flitch beam including two wooden beams while the steel plate is sandwitched with the help of bolts.

The word flitch is taken from flesh that means beams that have been cut lengthwise into strips.

Anyhow, the concept of a flitch beam is not that simple. That’s why in our today’s read, we’ve summed up every bit of detail that you need to know about flitch beam.

Beam

A beam is a structural member that primarily resists loads applied to a beam laterally and is used to transfer the load of slab to column.

There are different types of beams according to material. One is composite beam which is made of two different type of materials and joined together in such a way that they behave like a unit piece. For example, beam made of wood and steel. Flitch beam is a type of composite beam.

Flitch Beam

A Flitch beam is made by placing vertical steel plate between two wooden beams and then joining the three layers of different materials with bolts. That’s why we call flitch beam as composite or compound beam. These types of beams are now widely used in the construction of houses, aesthetic purposes, and other wooden framed structure to make a unique design.

Purpose of a flitch beam

Here’re some of the situations, where you have to use a flitch beam:

- Locations where solid wooden member is not possible due to depth limitations or heavy loads on it.

- To make the existing beam strengthened to resist higher loads. Just like we do in historic building renovations.

- A flitch beam is used as an alternative to high strength wooden beam to make the structure economical and of desired load carrying capacity member.

- Sometimes you need to utilize the appearance of wood due to aesthetic requirements of the project. So, without compromising the strength perspective you can use a flitch beam.

- We can find application of flitch beam in structures like houses, decks, and other primary wooden-framed structures.

Advantages of Flitch beam

The main benefit of flitch beam is that they have wood at their heart. They are lighter in weight and are best for timer framed building, garage, or any other type of extension. You can ensure the strength in your project as flitch beam can make any of your existing timber structure sturdier.

You also don’t have to use heavy or strong timber beams, as steel will take the loading. Anyhow, here’re some pros of flitch beam:

Also Read: What is a tie beam? – Details – Advantages – Reinforcement – Design

Light structural member

A beam made of steel or any other material having the same dimension as flitch beam is heavier than flitch beam due to which it become difficult to construct and install heavier beams. While flitch beam is lighter than steel beam, so it become easy to construct and to install these types of beams.

Also Read: Weight of concrete – Density – Concrete Slab – Driveways

Reduce dead load

As we know that these types of beams are made of steel plate sandwiched between two wooden strips or beams. Because of this unique design it decreases the dead load of beam and transfer less load on other members.

Economical

A beam made of steel is costly because of its high manufacturing cost in factories and require large number of labors for handling and installing purposes. Flitch beam is made of wood which is less costly and easily available. Because of its easy availability decreases the cost of wood and it also save labor cost because it does not require large labor for construction and installation.

Also Read: What is plinth Beam? – Purpose – Application – Types

Less time to construct

A beam made of concrete and other material require large time for construction. While a wooden beam save a lot of time and it can be installed in a very short time. It only requires joining the wooden members with steel plate and then bolt the three layers together. After bolting the beam ready to install at required location.

Less depth

Architectural design has been changing day by day due to changing demand of client and aesthetical purposes which create a dimensional restriction. A wooden beam of same dimensions can’t give a same strength as given by beam sandwiched by layer of steel. So, flitch beam needs less depth and fulfil the serviceability requirement of member. By using flitch beam issue of both architectural and structural design can be solved.

More strength

A beam made of wood of same dimensions give less strength as compared to flitch beam. The strength of beam increased by adding a steel plate between two wooden beams.

Also Read: Lintel Beam- Design – Meaning – Construction

Disadvantages of flitch beam

Just like other building elements, flitch beam does have some disadvantages. The biggest con of flitch beam is the higher cost because of difficulty in manufacturing and requirement of labor. Just because of this cost problem, we’re seeing use of flitch beam only for historic renovations. In heritage structures, we use flitch beam to reinforce existing lumber supports. So, let’s now see some of the disadvantages of flitch beam:

High Labor cost

These types of beams are manufactured by high skilled labors which demand high labor cost. So the cost of building or structure increases while using these type of structural members.

Strength Limitations

A flitch beam strength is more as compared to wooden members but in case of heavy load of multistoried buildings the flitch beam is not capable of taking the heavy building loads. This is one limitation of flitch beam.

Old construction technique

These types of beams are rarely used nowadays due to its size and strength limitations. The world is shifting towards more reliable and high strength construction materials. A composite beam made of concrete and steel bars are more preferred these days because of its high strength and small dimensions which is more economical.

Also Read: What is a Pier and Beam Foundation? – Cost, Pros- Cons

Durability and weather resistance

As we know that flitch beam is made of wooden members and steel plate. The durability and weather resistance of wooden members is less as compared to concrete and steel beams.

Less design life

The durability of wooden beams and members is less due to which lifetime of these type of structures is less as compared to steel and concrete beams.

The bottom line

Flitch beams are used in construction of houses, hotels, shopping malls to make a unique design of buildings made of wood, to fulfill the load and serviceability requirements and for aesthetic purposes. While on the other hand their applications are limited due to less skilled labor, design, and dimension limitations.

Also Read: Hempcrete Blocks – light weight REPLACEMENT of Concrete