Gone are the days when a water canal projects are delayed by a time taking rip rap erosion control works.Why?Yes, because now the erosion control by concrete blocks is a fast and easy solution.

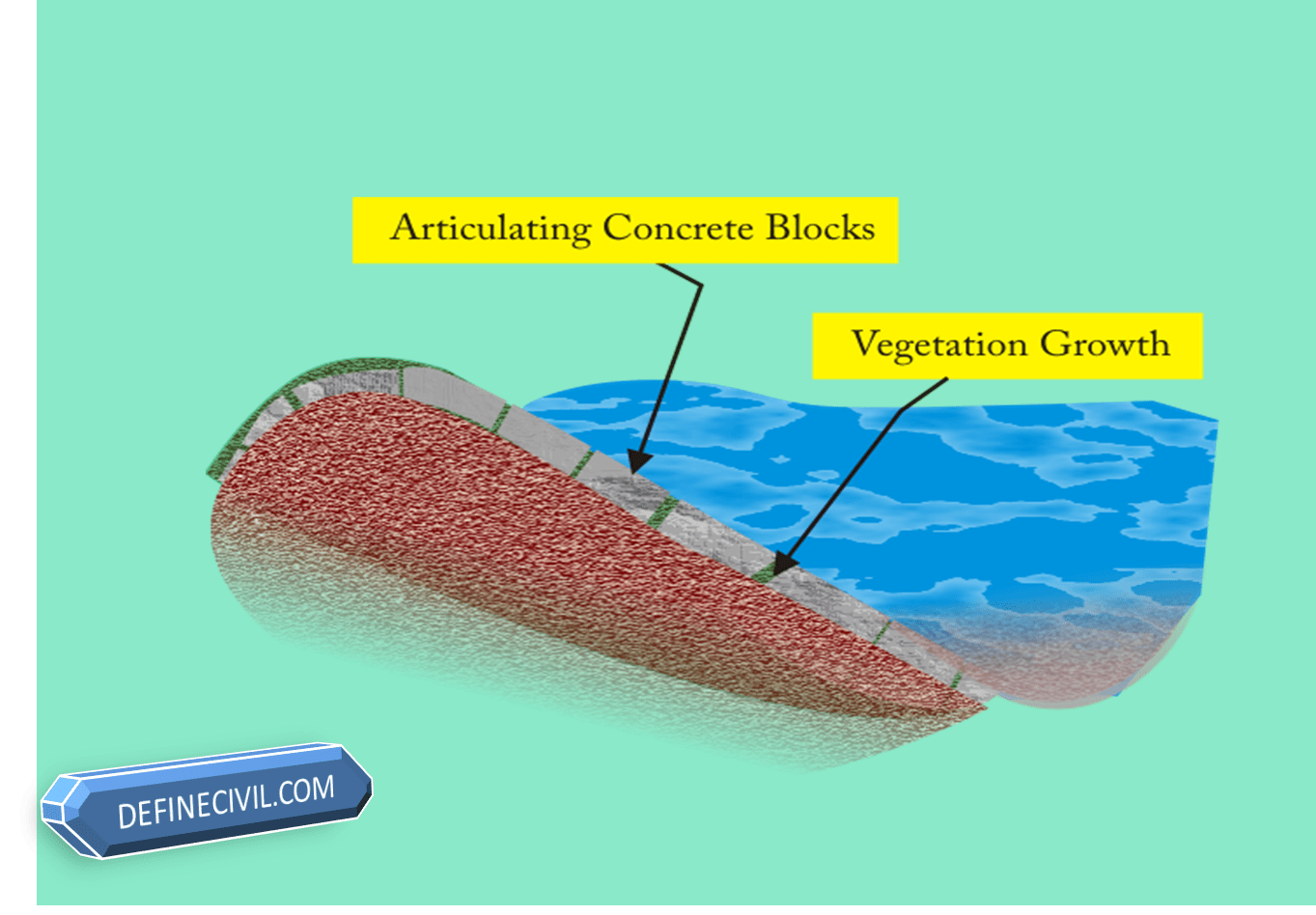

These blocks can be used in projects involving light to moderate water wave and open-channel flow conditions. These concrete blocks are termed as Articulated Concrete Blocks.

These blocks provide a cheap alternative to the traditional riprap; they provide approximately 50% of the cost saving. Articulated concrete block price is coated as $10 to $18 per square foot of the area.

According to watershedgeo; the comparison of the price for various erosion control systems is presented as follows :-

- HydroTurf – $5 to $8/sf

- 24″ Rip Rap – $4 to $10/sf

- 6″ Concrete Paving – $8 to $12/sf

- Articulated Concrete Block – $10 to $18/sf

The system formed for erosion control by concrete blocks is known as revetment system or concrete erosion control mats.

Revetment system, in river engineering or irrigation engineering, is defined as a sloping / inclined structure that is placed on the banks of the water ways for erosion control as well as fortification.

erosion control by concrete blocks system secures the slopes by forming a solid defense against erosion, scouring by absorbing the energy of incoming water waves.

Interlocking Erosion control blocks

Erosion control by interlocking concrete blocks is a best option because concrete blocks are heavy that can remain stationary during flow of water above or around the block. These articulated concrete blocks prevent the erosion of the underlying earth material that could otherwise wash out during the flow of river.

Erosion Control Concrete Blocks has proven to be an aesthetic and functional alternative to dumped stone riprap, gabions, structural concrete and other heavy-duty, durable erosion protection systems.

The shape of erosion control blocks can be made so as to be interlocking, or interengaging, and facilitate the hydraulic stability of the block installed in a waterway, or the like.

Also Read: Concrete Block Wall CMU wall.

Types of Erosion Control by Concrete Blocks

While considering the restraint of blocks in case of movement; the erosion control concrete blocks are of two types:

- Interlocking Concrete Blocks

- Interengaging Erosion Control Concrete Blocks

In case of the interlocking type of concrete blocks, the lateral movement of the block is prevented by the adjacent block. But in case of interengaging type of concrete blocks, the stability between blocks exists only in one lateral direction and not in the perpendicular direction.

Anyhow, the flexibility and elasticity of the interengaging concrete blocks is more than that of the traditional interlocking concrete erosion control blocks.

Installation of Concrete Blocks

Generally there are two methods that currently prevail for the installation of the interlocking articulating concrete blocks:-

- Interlocking after installation

- Interlocking at the plant

In the first method the erosion control blocks are installed manually i.e. labor carries the blocks and place them side by side. But in some cases, depending on the ground conditions, a geotextile fabric is placed on the ground before the installation of the erosion control.

After the placement of blocks, synthetic rob is made to run through the channels within each blocks and is threaded to form a flexible unit. In such type of blocks, two or more cable channels are formed through the blocks so that cables can be threaded easily.

In the second type of installation, the flexible unit or matrix or mattress of the erosion control blocks is interlocked or interengaged together at the plant. These mattresses are then lifted by these cables and loaded on the hauling trucks.

After reaching the site for installation, a large crane or spreader bar assembly is used to lift these units from the cables off the truck and placed on to the slope one by one. A number of such mattresses are installed together and in such a way full erosion control system is provided for the cable channel.

Also Read: How much does a cinder block weigh?

Advantages of Erosion Control Concrete Blocks

Comparing with that of the traditional grouted or non-grouted riprap the erosion control by concrete blocks has many advantages and applications that are as follows :-

- It provides much hard armor surface as compared to that of a simple rip rap with enhanced hydraulic performance characteristics.

- The flexibility of the concrete blocks matrix allows it to be placed on any existing area.

- As 20 % of area in case of such concrete blocks is open so It has the ability to allow vegetation to grow for enhanced slope stability, preventing erosion of the exposed soil as well strength of the entire system and stabilize the land.

- The enhanced stability character of the erosion control concrete blocks find its applications in channels, shorelines, boat ramps etc.

- The erosion control concrete blocks are very easy to install and they are environmentally very much friendly.

- Their flexibility allows them to be assembled to any required size and shape depending on the requirements of the project.

- These concrete erosion control blocks effectively avoids erosion by dissipating the wave energy as well scouring and they also can promote drainage by an improved landscape.

- Although they are made of concrete but are comparatively light weight and are easy to fix without the use of heavy equipments i.e. in case of non-availability of heavy machinery they can be fixed manually by labors.

- As these blocks conform to the ground contours, they can relieve the hydrostatic pressure and can resists the lateral movement.

- Due to open area, fast and easy installation they are very economical and cheap as compared to large diameter riprap.