So now you have got the turbidity curtain and are now looking for curtain installation process so here is a step by step guide for you.

I am actually glad that you have chosen the turbidity curtain for your marine construction, dredging and remediation projects.

You top priority here is that you want to control the turbidity and sediment in the water body because in order to be in compliance with environment protection regulations you are bound to do that.

Enough diligence is required for correct and precise on-spot turbidity curtain installation. And you must not neglect to follow the incoming guidelines as the success or failure of the turbidity curtain is more dependent on how accurate the installation is.

You must also not ignore the maintenance of turbidity curtain as for a long run I must recommend that a professional service for turbidity curtain installation and maintenance be arranged or hired to avoid any failure in future.

If you have landed on this article accidently and wondering what actually turbidity curtain is? So proceed but for readers in a hurry who just want to know installation steps please jump to the guideline below.

What is turbidity Curtain?

A turbidity curtain is also known as silt fence or turbidity barrier. you can read here.

In most of the cases turbidity curtains are installed in waterways to avoid and inhabit pollution by turbidity and disturbed sediment that are caused by civil works / activities adjacent to marine construction and in dredging and remediation projects.

Working of turbidity Curtain

A turbidity curtain must not be confused with a filter curtain.

The working of the turbidity curtain is that it creates a localized area in a water body where the suspended and dispersed sediments got some time and silt settles without migrating to complete water body.

turbidity curtain or silt screen is also used in on-land construction to avoid escape of dirt and sediment by surface runoff or storm water.

The installation of both types of turbidity curtain is different but with following standard guidelines both can be effective in forming a sediment containment area on a construction site.

Typical Structure Detail of turbidity Curtain

Now you know the basics of turbidity curtain; what it is? What does silt curtain do or how it works?

So let’s move on to the next step that how the turbidity curtains are installed?

Before understanding the installation you must know the basic structure of a turbidity curtain.

Although there are many types of turbidity curtains for on-ground and in-water silt curtailment but the most common of all are the in-water floating type of silt curtain called floating turbidity curtain.

The body of the turbidity barrier is composed of Nylon of 625 grams weight which is also termed as reinforced vinyl. This depth of the skirting is dependent on the needs of the project.

At the top, floating is provided by 6” square polystyrene foam.

Sometimes stress plates are affixed with the nylon fabric along with cable in situations with flowing water, high winds, or other strong loads.

A typical block of turbidity curtain is of size 4” x 4” up to 12” x 2”; this size and buoyancy requirements depend on weight and length of curtain. Each block has grommets at the edges that are tied together with a wire for joining the silt curtain.

At the tip of the block galvanized chain blast is provided with hooks for joining. Along with stress blocks sometimes coated galvanized cables are also attached to strengthen the fabric against high wind tides.

The blocks are connected together by vertical PVC slot connected that are fixed with the help of stress bands.

The following exhibit explains the typical structure of a turbidity curtain.

turbidity Curtain Installation a Step by Step Guide

The steps I am going to explain for turbidity curtain installation is a general guide for how to install the silt curtain but it must be kept in mind that each project has its own variables that must be considered before arriving at a decision.

The different types of turbidity curtains like Type 1, Type 2, Type II, HD, DOT and other US manufactured turbidity Curtains can be opted for specific needs and demands of a project.

-

Layout and Configuration

The turbidity curtains are supplied in sections of length 50 or 100 feet length that have furled skirts and are placed in pallets. Numbers of pallets are procured depending on the length of the silt curtain required for the project. Sometimes the pallets are numbered for ease in identification and assemblage.

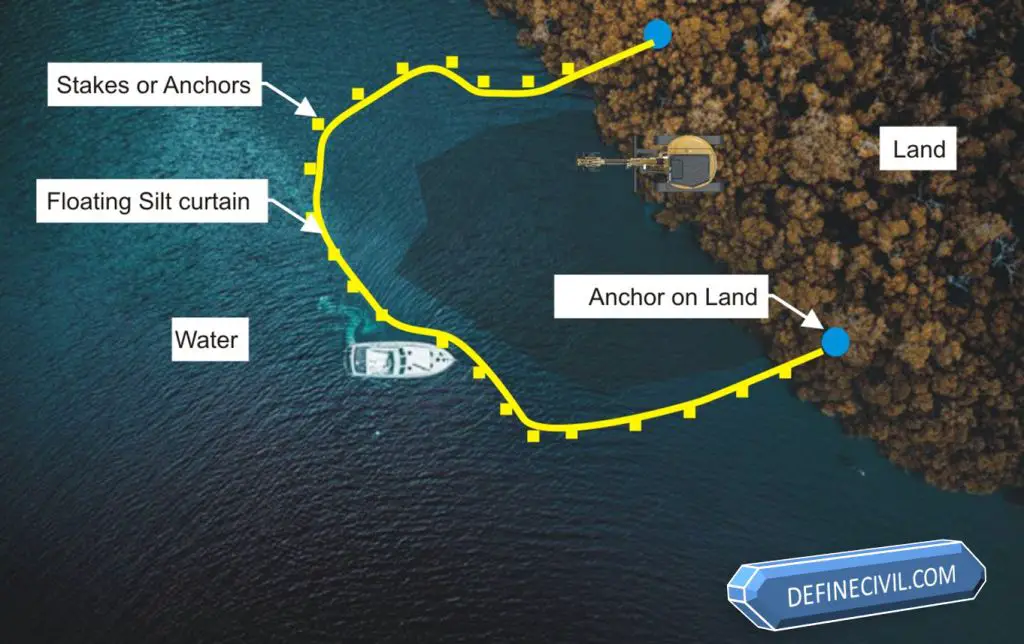

The anchors are fixed on the land and it is tried that these anchors be close to the shore. Stakes or anchors are fixed after every 50 feet or so at corners. This anchorage system is very crucial as its efficacy during tidal movement and waves depend directly on the effectiveness of the anchors fixed.

[su_box title=”Pro Tip” style=”bubbles” box_color=”#3b5fb8″ radius=”7″]The construction layout and the area that is expected to be effected due to the floating debris and silt in water body is identified and surveyed after which the required length of the silt curtain is decided and is marked on the site.[/su_box]

- Setup and Assemblage

The identified numbers of pallets are laid down as near as possible to the deployment zone for easy assemblage. It was ensured that a large enough is decided for layout the silt curtain. The furled silt curtains are connected together by hooks and wires as per the configuration for the specific type.

After fixing and assemblage the curtains are towed into the water at the desired location i.e. where the anchors were fixed. These curtains are then fixed with the anchors in furled position. It must be confirmed that the skirt should not be twisted.

These untwisted and furled curtains after anchoring to the right location, are opened and allowed to drop in place. It must be kept in mind that the curtain must not be moved under water unfurled.