The word hardened concrete means the concrete which has been initially set and is not fresh like a workable and plastic concrete.

So we can say that the word hardened concrete specifies its stage of “plasticity” which is gone and now the concrete is in hardened form after setting.

[su_note]Workability and related properties of fresh concrete are essential for transport and laying.[/su_note]

The properties which determine the quality of the hardened concrete broadly fall into the following three groups :

- Strength.

- Durability.

- Dimensional stability.

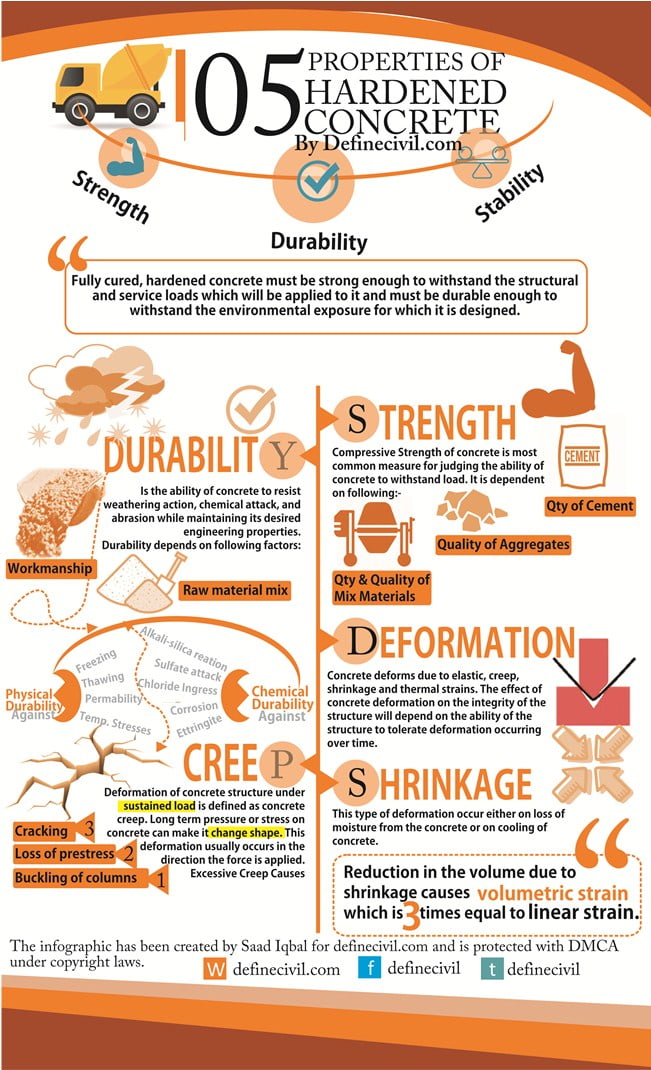

Fully cured, hardened concrete must be strong enough to withstand the structural and service loads which will be applied to it and must be durable enough to withstand the environmental exposure for which it is designed.

If concrete is made with high-quality materials and is properly proportioned, mixed, handled, placed and finished, it will be the strongest and durable building material.

Below are the properties of hardened concrete:-

- [su_list icon=”icon: anchor” icon_color=”#c12c36″]

- Strength

- Creep

- Durability

- Shrinkage

- Modulus of Elasticity

- Water Tightness

[/su_list]

Strength of Hardened Concrete

The compressive strength of concrete is the most [su_highlight]common measure for judging not only the ability of the concrete to withstand load,[/su_highlight] but also the quality of the hardened concrete.

Test results obtained from compressive strength tests have proved to be sensitive to changing mix materials and mix proportions as well as to differences in curing and compaction of test specimens.

The most significant factor influencing compressive strength is the amount of cement in the mix, relating to water:cement ratio (W/C).

Effect of W/C Ratio

The lower the W/C, the higher the strength for similar other materials.

i.e. inverse relation.

Other factors include

- the amount of mineral component in the cement

- quality of the aggregate used a

- quality of admixtures.

[su_box title=”IMPORTANT” box_color=”#4be97f”]Prior to concreting, trial mixes are conducted to ensure that the proposed on-site mix proportions and the properties of the raw materials to be used will produce concrete that complies with the requirements of the specification.[/su_box]

It is, however, possible to obtain an approximate strength when the relationship between W/C and strength is known for a given set of materials.

The main factors affecting the quality of concrete relate primarily to:

- Control of an increasing number of raw materials.

- The use of different materials with differing concrete making properties.

- Proportioning materials to provide concrete with different properties in the fresh and hardened state.

- Production processes.

- Sampling and testing: Between batches of concrete made with identical proportions of the same raw materials, there will be some inherent and acceptable variation in quality.Any quality control system employed should be able to quickly detect gross errors in order to initiate effective corrective action.

[su_button url=”https://definecivil.com/wp-content/uploads/2018/07/properties-of-hardened-concrete-infographic.jpg” style=”bubbles” icon=”icon: arrow-down”]Download the Above Infographic[/su_button]

I have created this infographic about properties of hardened concrete but you can embed and share it on your website with credits to us. Happy Sharing!

[su_box title=”Embed the above infographic” style=”bubbles” box_color=”#3b5fb8″ radius=”7″]<a href=”https://definecivil.com/wp-content/uploads/2018/07/properties-of-hardened-concrete-infographic-2.jpg”>Checkout a very interesting infographic about properties of hardened concrete developed by definecivil <img src=”https://definecivil.com/wp-content/uploads/2018/07/properties-of-hardened-concrete-infographic-2.jpg” border=”0″></a> [/su_box]

DURABILITY OF CONCRETE

Durability of concrete may be defined as the ability of concrete to resist weathering action, chemical attack, and abrasion while maintaining its desired engineering properties.

Durability is a very important property of hardened concrete.

It normally refers to the duration or life span of trouble-free performance.

[su_box title=”IMPORTANT” box_color=”#4be97f”]Different concretes require different degrees of durability depending on the exposure environment and properties desired.[/su_box]

For example, concrete exposed to tidal seawater will have different requirements than indoor concrete.

The following factors are of equal importance in influencing the durability of a concrete structure:

- Design and detailing of structural elements.

- Construction practices, workmanship and supervision.

- Concrete raw materials and mix proportions.

- The environment to which the concrete is exposed.

There are many types but the major ones are:

- Physical durability of concrete

- Chemical durability of concrete

Physical Durability

Physical durability is against the following actions

- Freezing and thawing action

- Percolation / Permeability of water

- Temperature stresses i.e. high heat of hydration

Chemical Durability

Chemical durability is against the following actions

- Alkali Aggregate Reaction

- Sulphate Attack

- Chloride Ingress

- Delay Ettringite Formation

- Corrosion of reinforcement

DEFORMATION IN HARDENED CONCRETE

Concrete deforms due to elastic, creep, shrinkage and thermal strains. The effect of concrete deformation on the integrity of the structure will depend on the ability of the structure to tolerate deformation occurring over time.

CREEP;

Deformation of concrete structure under sustained load is defined as concrete creep.

Long term pressure or stress on concrete can make it change shape.

This deformation usually occurs in the direction the force is applied.

[su_box title=”Interesting” box_color=”#4be97f”]Without the ability to creep, concrete would simply be too brittle for use in the majority of structures.[/su_box]

However, creep also may have detrimental effects such as increased deflection resulting in cracking, loss of prestress, and buckling of slender columns.

It is therefore important that the designer takes the necessary steps to allow for creep in the design of concrete structures.

Creep consists of two components:

- Basic creep: The creep that occurs under conditions where there is no drying.

- Drying creep: The additional creep that occurs when the loaded concrete is drying.

Shrinkage

These deformations occur either on loss of moisture from the concrete on cooling of concrete

- Shrinkage is the reduction in the volume of a freshly hardened concrete exposed to the ambient temperature and humidity

- Reduction in the volume due to shrinkage causes volumetric strain. Volumetric strain is equal to 3 times the linear strain

- In practice, shrinkage is measured simply as a linear strain Types of Shrinkage Shrinkage in concrete is caused mainly by loss of water by evaporation or by hydration of cement. However, fall of temperature and carbonation may also cause the shrinkage Following are the various classifications of the shrinkage depending upon the cause of shrinkage:

Types of shrinkages, caused due to loss of water

- Plastic shrinkage occurs due to loss of water by evaporation from freshly placed concrete while the cement paste is plastic

- Plastic shrinkage is higher at a higher rate of evaporation of water, which in turn depends on the air temperature, the concrete temperature, the relative humidity of the air and wind speed

- Plastic shrinkage of concrete is higher at a larger cement content (i.e. smaller the aggregate content by volume) of the mix.

- Drying shrinkage occurs due to loss of water by evaporation from freshly hardened concrete exposed to air

- when the concrete which has undergone to drying shrinkage is subsequently placed in water (or at higher humidity) it will swell due to absorption of water by the cement paste getting partial recovery from the shrinkage

- The amount of shrinkage recovered on placing the concrete in water (or at higher humidity) is called “reversible moisture movement or reversible shrinkage” and the un-recovered shrinkage is called “residual or irreversible shrinkage” ∴ Drying shrinkage = reversible shrinkage + irreversible shrinkage Reversible shrinkage = 40 to 70 % of drying shrinkage

- Reversible shrinkage will form a greater proportion of the drying shrinkage if concrete is cured so that it is fully hydrated before being exposed to drying

- Irreversible shrinkage will form a greater proportion of the drying shrinkage if concrete is not fully hydrated before being exposed to drying, or drying is accompanied by extensive carbonation, or both

- Autogenous shrinkage occurs due to loss of water by self-desiccation of concrete during hydration

Rheological properties of Hardened Concrete

Do you know concrete in its fresh state is among those liquids having very complicated properties?

For those who don’t know what rheology of concrete is;

Basically the word “rheology” is used for study of complicated fluids for their deformation and their flow while in plastic or liquid state.

Concrete when fresh has workability and tendency to flow; this rheology of fresh concrete is utilized while placing and compacting concrete.

The stability, flowability and compactability are some of the rehological properties of fresh concrete.

What do you think; are these factors will influence the concrete in hardened state?

Obviously, they will; the deformation, durability and sustainability are all depending on the above properties and would surely be going to influence hardened concrete.

TESTS ON HARDENED CONCRETE

Different types of tests are conducted on Hardened Concrete to maintain the proper design strength and quality of concrete construction at optimal level.

Normal tests on Hardened Concrete:

The following primary destructive tests are performed on hardened concrete:

(a) Cube test: Compressive strength of hardened concrete is performed through cube test. Get more information on Compressive strength tests on Concrete Cube.

(b) Tensile splitting test on concrete cylinders(theconstructor.org/concrete)

(c) Flexure test: A plain concrete specimen is examined to failure in bending. The theoretical maximum tensile stress at the bottom face at failure is measured. This is called the modulus of rupture. It is around 1.5 times the tensile stress obtained with the splitting test.

(d) Concrete core test: A rotary cutting tool is used to slice cylindrical cores from the completed structure. The core is drenched, capped and examined in compression to get the quantity of the concrete strength in the original structure. The proportion of core height to diameter and the location, where the core is acquired, influence the strength. The strength is minimum at the top surface and raises with depth through the element. A proportion of core height-to-diameter of 2 provides a standard cylinder test. Get more information on Core Sampling and testing of concrete.

Non-destructive tests: The primary non-destructive tests for strength on hardened concrete areas are given below:-

(a) Rebound hammer (hardness) test

For the rebound hardness test, the schmidt hammer is utilized. Under this test, a metal hammer occupied against the concrete is sustained with another spring-driven metal mass and rebounds. The amount of rebound is documented on a scale and this highlights the strength of the concrete. As the rebound number is greater, the strength of the concrete will also increase.

(b) Ultrasonic pulse velocity test

Under the ultrasonic pulse velocity test, the velocity of ultrasonic pulses that transmit through a concrete section from a transmitter to a receiver is calculated. The pulse velocity is interrelated opposed to strength. If the velocity becomes higher, the strength of the concrete is increased.

(c) Other non-destructive tests: These tests are done through Equipment to compute the following :-

1. Crack widths and depths

2. Water permeability and the surface dampness of concrete

3. Depth of cover and the location of reinforcing bars

4. The electrochemical potential of reinforcing bars and therefore the existence of corrosion

Chemical tests on Concrete: There are a series of chemical tests to compute the following :-

1. Depth of carbonation

2. The cement content of the original mix

3. The content of salts like chlorides and sulphates which may react and result in decomposing of the concrete or erosion of the reinforcement.