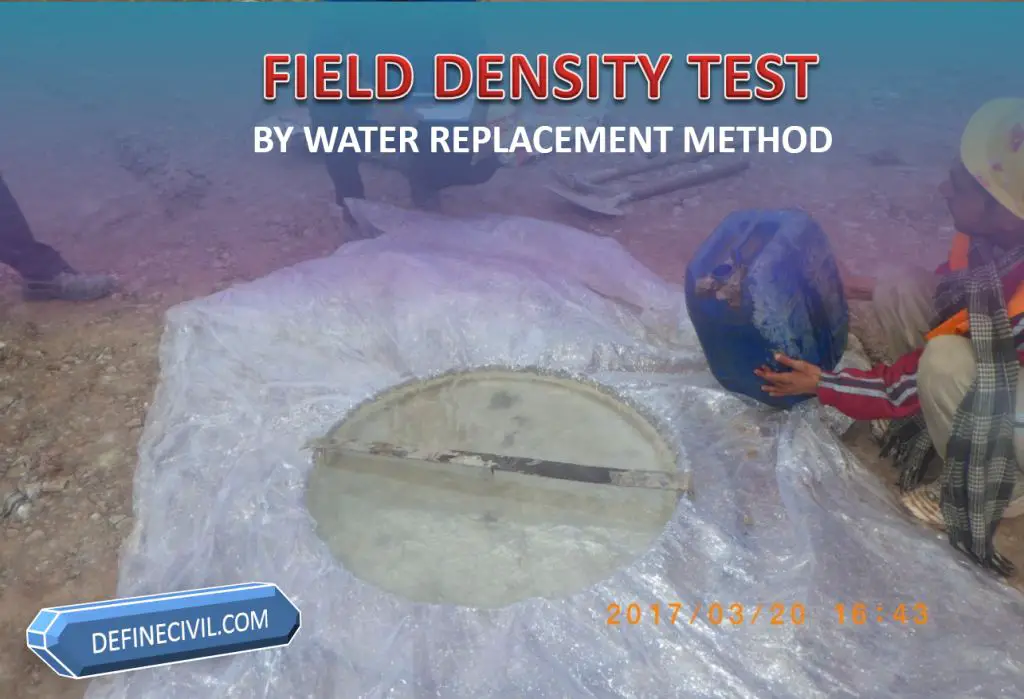

Water replacement method is used for determination of field compaction or field density of soil and gravely fills. The method is used for soil fills containing particles larger than 75 mm such as earth embankments, road fills, or structural backfills. The test method is standardized per ASTM D5030.

As I’ve explained in my earlier posts about different methods for field density; each type of field density test is suitable for a certain type and size of soil or gradation.

It is needless to say that most popular type of field density test method is sand replacement method. At times, the sand replacement method is not recommended for determination of field density and in such cases water replacement method is used.

Water Replacement Method of Field Density Test

For large test pits of volume between 3 to 100 ft3 (0.08 to 2.83 m3) and with material of particle size over 5 inches (125 mm); water replacement method is used for determination of Field Density. As a reference I have enlisted below some methods and its recommended test pit size.

| Sr. No. | Description of Field Density Test | ASTM Standard | Recommended Test Pit Size | Remarks |

| 1. | Sand Replacement Method | D4914 | 1 ~ 6 ft3 (0.03 ~ 0.17 m3) | |

| 2. | Rubber balloon Method | D2167 | Smaller than 1 ft3 (0.03 m3) | |

| 3. | Water Replacement Method | D4914 | 3 ~ 100 ft3 (0.08 ~ 2.83 m3) | |

| 4. | Sand Cone Method | D1556 | Smaller than 1 ft3 (0.03 m3) |

Significance and Use

I’ve personally find applications of Field Density test by Water Replacement method in hydropower or Dam projects. Bulky embankments and large particle sized backfills were evaluated for their achieved field density by water replacement method.

The in-place unit weight or field density of the soil or rock of size over 3 inches (75 mm) is determined using water replacement method. The achieved dry density after comparison with maximum dry density or proctor density is either passed or failed based on agreed criteria for compaction, usually 95% for general uses.

Apparatus

Following are the set of equipment used as apparatus for the test

- Metal Template: a 1.8-meter diameter circular metal ring is used for guiding the pit excavation. The steel ring is of height sufficient enough to avoid water splash due to wind action.

- Lining plastic sheet: to accommodate water in the excavated pit usually a polythene water proof sheet is used thin enough to allow displacement under the weight of water to line entirely the outline of the excavated pit.

- Physical balance: a digital weighing balance or scale should be used with accuracy of 0.1 g.

- Drying oven: a suitable oven for drying the soil sample when determining its dry weight.

- Chisel & knife: for excavating through the embankment around the metal ring.

Procedure

- The surface is properly prepared, cleaned and levelled for firm seating of the template ring. The template is placed on the designated place as per Engineer’s recommendation. No empty gap or space should be there between the template and the ground. If required, the space should be filled by mortar or clay.

- The template edges should not be sharp enough to damage plastic sheeting or liner and if required, can duct tape can be applied on the sharp edges.

- The first step is to determine the volume of space between the surface of soil and the water-level reference point marked / selected on the template.

- It is not necessary that the template is levelled i.e. it can be in a sloping position but the slope should be less than 5%.

- For determining the volume of water between the top of soil and water-level surface mark, the plastic sheeting is spread on the template before excavation and the water is poured in the ring.

- A carpenter’s square is used to determine the water-level reference and is then marked on the template ring. The volume of the water used is determined and is noted.

- The next step is to excavate the pit in the soil using a shovel or chisel. In case of large sized pit or large sized boulders excavator or backhoe might be required. All the removed soil is preserved in a closed container and take care of the loose material as well.

- After excavating, plastic sheeting is spread in the test pit and is filled with water up-to water-level reference point.

- The total mass of the water required to fill the excavated pit is determined and from there volume is calculated using density of water i.e. 62.3 lb/ft3.

- Take samples of soil mass preserved for moisture determination.

- The dry density or dry unit weight of the soil is estimated by using following equation.

- ϒd = ϒb / (1+m) where m is the moisture content in fraction

Observations and Calculations

Step: 1 Determining volume between top of soil and water-level reference line

Mass of water in container = Mw1

Mass of water after filling the surface of soil and water-level reference line = Mw2

Mass of water required to fill the gap = Mwg = Mw1 – MW2

Volume of gap between top of soil & water level reference line = Vg = Mwg / density of water

Step:2 Determining the volume of soil pit

Mass of water in container = Mw2

Mass of water after filling the pit up to water-level reference line = Mw3

Mass of water required to fill the pit = Mwp = Mw2 – Mw3

Volume of pit only = (Mwp / density of water )-Vg

Bulk density = ϒb = weight of soil from pit / volume of pit only

ϒd = ϒb / (1+m) where m is the moisture content in fraction.

![Engineering Communication by Knisely [PDF] [FREE DOWNLOAD]](https://definecivil.com/wp-content/uploads/2021/05/Editorial-Markup-Stop-Start-Continue-Brainstorm-Presentation-100x100.jpg)