Fineness of cement is another quality control parameter that experts keep in check of at the laboratory. The size of the particles of OPC impact the surface area and the heat of hydration.

I’ve already explained the definition in my previous article on different physical properties of cement. So, if would reproduce my answer to the question – what is fineness of cement? as;

Fineness of cement Definition

Fineness of cement is an important physical property of cement that defines the particle size and the surface area of cement particles. It is expressed in %age when determined as a modulus with sieving or units of cm2/gm or m2/kg in case when determine by Blaine air permeability apparatus.

So, in the laboratory we can determine it by using tests methods of sieving and air-permeability apparatus.

It is important to note that in common cement types, the smallest particle is of size 1.5 micron while the average size is about 10 micron. Now, in commercial cement about 30% of the particles are in size less than 7 microns. But this division or distribution varies between different manufacturers and thus it is crucial to determine the fineness modulus of cement.

Fineness modulus is an empirical figure that is determined in the laboratory to express the total percentage of the sample of cement retained on a 90 micro meter size sieves divided by 100 as averaged.

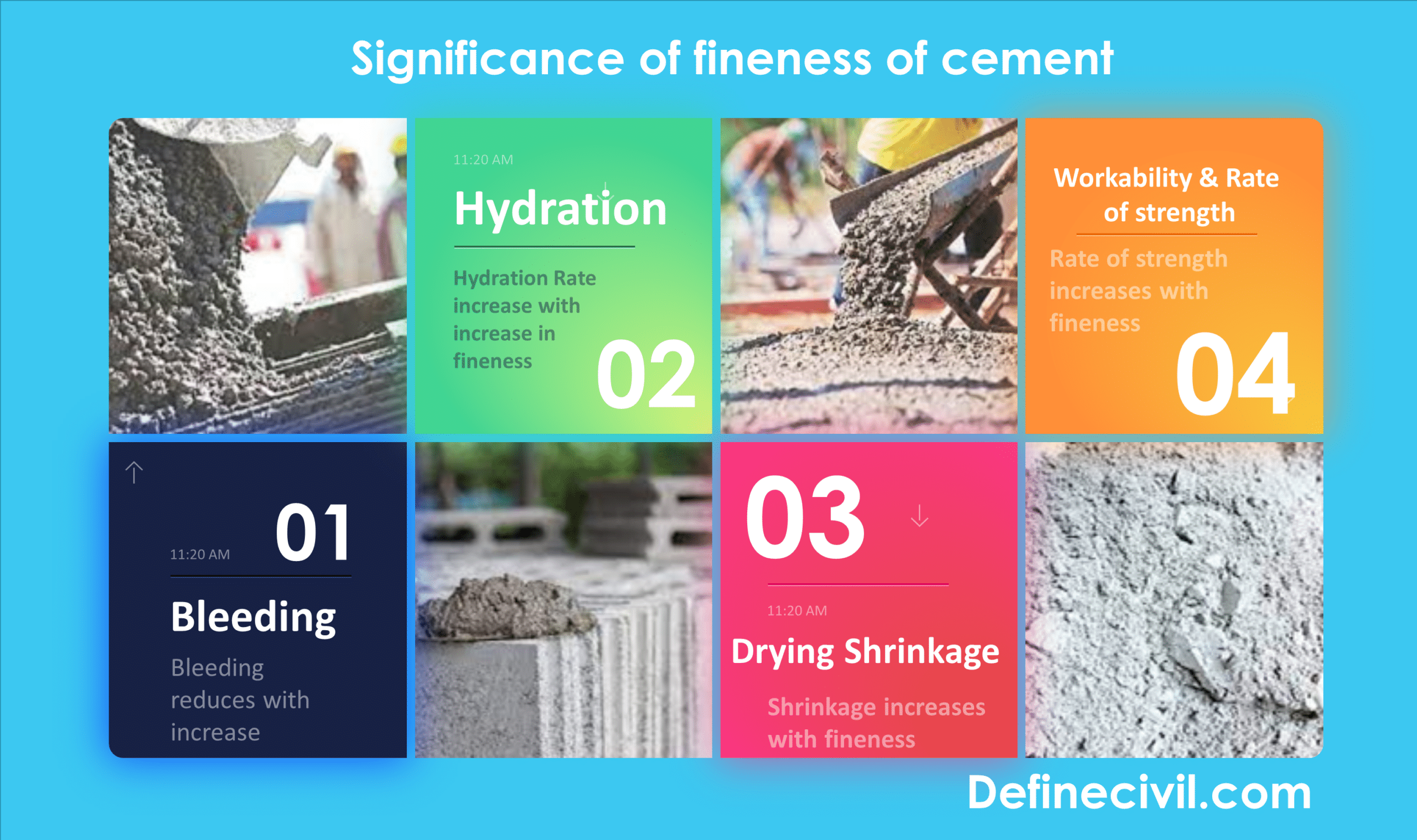

Significance

The fineness of cement indirectly impacts the rate of hydration and thus heat of hydration. Now when you mix cement with water a layer is formed around the particles. The smaller the particles, the more the surface area, and the water requirement for hydration reaction.

The smaller particles react a lot quicker and thus the particle size distribution or fineness is critical for the final strength of OPC cement mix. Here’s how we can relate fineness with other properties of cement

- Bleeding – which is the appearance of cement slurry on top the concrete mix – reduces considerably by increasing the fineness of cement. By increasing the surface area of particles more water gets absorbed into the cement particles.

- Hydration – When you increase the surface area of cement, the rate of hydration and heat would be increased. This means you require more water content or water cement ratio to meet the desired properties. If you want to read more in detail about water cement ratio, read on this article.

- Drying shrinkage – the phenomenon by which the concrete contracts as a result of moisture loss upon drying – increases as a result of fineness. That is because you’re adding more water to the concrete mix and that would increase the chance of shrinkage.

- Workability of fresh concrete mix – Now as the surface area of cement particles would be more; there’d be more adhesion between the particles. So, there’s a need of more water addition to achieve a given consistency or workability for a concrete mix. If you’d like to read more about what is workability and what are some factors that effect it. Read on with this article.

- Rate of Strength – You can increase the rate of strength gain by using finer cement. This is crucial in premix or precast concrete members like girders or slab members.

Have a look at the image below for review;

Fineness of Cement test

Standards

Different standards have been formulated by International committees for determining the fineness of cement; some are as below:

- AASHTO T 98 and ASTM C 115: Fineness of Portland Cement by the Turbidimeter.

- AASHTO T 128 and ASTM C 184: Fineness of Hydraulic Cement by the 150-mm (No.100) and 75-mm (No. 200) Sieves

- AASHTO T 153 and ASTM C 204: Fineness of Hydraulic Cement by Air-Permeability Apparatus o AASHTO T 192 and

- ASTM C 430: Fineness of Hydraulic Cement by the 45-mm (No. 325) Sieve.

By Sieving

For determination with sieving as per IS code, we require following apparatus

Apparatus

- Sieve: 90 micron sieve that would comply with IS 460 (Part 1): 1985 and Part 3 1985. The sieve shall be of firm, durable frame with free of any visible irregularity in mesh size. A tray can be fitted beneath the frame and a sieve lid at the top to avoid material loss during sieving.

- Balance: We need a physical balance capable of weighing 10g to the nearest of 10mg.

- Glass rod and stoppered jar: for removing lumps and agglomerates.

- Nylon Bristol brush – for cleaning sieve

- Sieve shaking table – for shaking sieve without a trouble.

Procedure

The standard procedure for determining fineness of cement by sieving is as follows:

- First you need to stir and shake the cement sample in a stoppered jar for minimum 2 minutes to disperse lumps and agglomerates. After a gap of 2 minutes, stir the powder gently with dry rod to uniformly distribute the fines throughout the sample.

- Now fit the tray under the sieve and take 10 grams of cement sample being careful to avoid loss. Then fit the lid on the top and agitate the sieve manually or by using shaker to pass the fine material through the sieve.

- Remove the sieve and weigh the residue carefully. We’ll express this weight as the percentage of the 10 grams taken previously.

- We’d repeat the steps 2 and 3 to get minimum of 3 readings and would take the average at the end.

We can prepare the lab report as:

R1 = weight of cement residue in grams left after sieving.

R2 = weight of second cement residue in grams left after sieving.

R3 = weight of third cement residue in grams left after sieving.

Ravg = (R1+R2+R3) / 3

This Ravg as %age would give you the fineness of cement sample.

Please note that the standard deviation for repeatability is about 0.2 percent while the reproducibility is about 0.3 percent.

By air-permeability apparatus as per IS:5516

In this method a specialized apparatus is used termed as Blaine’s air permeability apparatus. This apparatus draws a definite amount of air through a prepared bed of cement. This total surface area expressed as square centimeters per gram is fineness.

Recommended value of fineness

Fineness limit;

It should not exceed following percentage by weight for different types of cement;

- Ordinary portland cement = 10%

- Rapid hardening cement = 5%

- Low heat cement = 5%

It is important to note that the particle size fraction below 3 microns have more impact on the strength of concrete at one day while the size of 3-25 have more effect on the 28 days strength of the mix.

That’s not all!

Bored of reading text? Don’t worry! I’ve made this super exciting Explainer video on the fineness test of cement.

Watch & Enjoy!

If you’d like the article, please share it with your friends. Don’t forget to subscribe to our youtube channel https://www.youtube.com/c/saadiqbalengr. Also send your comments and thoughts below.

[su_box title=”Don’t Forget to Read these relevant article” style=”glass” box_color=”#f64420″]Read these articles for more in-depth knowledge of the subject

[/su_box]

[su_box title=”Don’t Forget to Subscribe to Our Channel” style=”glass” box_color=”#f64420″]Are you willing to stay tuned to a whole lot of fun and information related to construction and civil engineering? if Yes than what you’re waiting for? Just hit this subscribe button and stay updated when it matters the most :

[su_button url=”https://youtube.com/c/saadiqbalengr/” target=”blank” style=”soft” background=”#c74740″ size=”7″ center=”yes” icon=”icon: youtube”]Subscribe Now[/su_button]

[/su_box]