Laminated veneer lumber (LVL) is one of the most commonly engineered wood materials used in construction. It is a composite product made of many thin layers of veneer that align the length of the final timber.

In our today’s blog post we’ll talk about LVL beam sizes, LVL beam span, LVL beam span calculator, LVL Beam price of different sizes like 30-ft, 24-ft, and 20-ft.

You’ll find the LVL calculator at the end of the post;

We’ll also talk about the basic manufacturing steps, advantages, and disadvantages of LVL compared to other structurally engineered wood-based products.

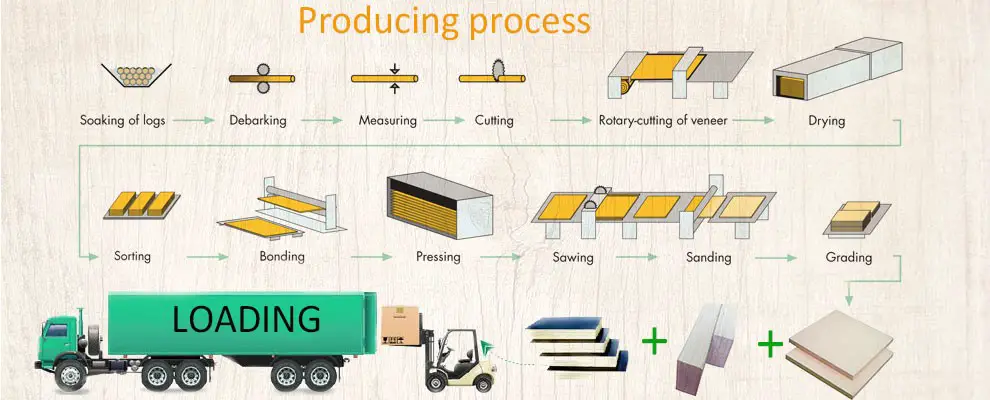

Production Procedure of LVL:

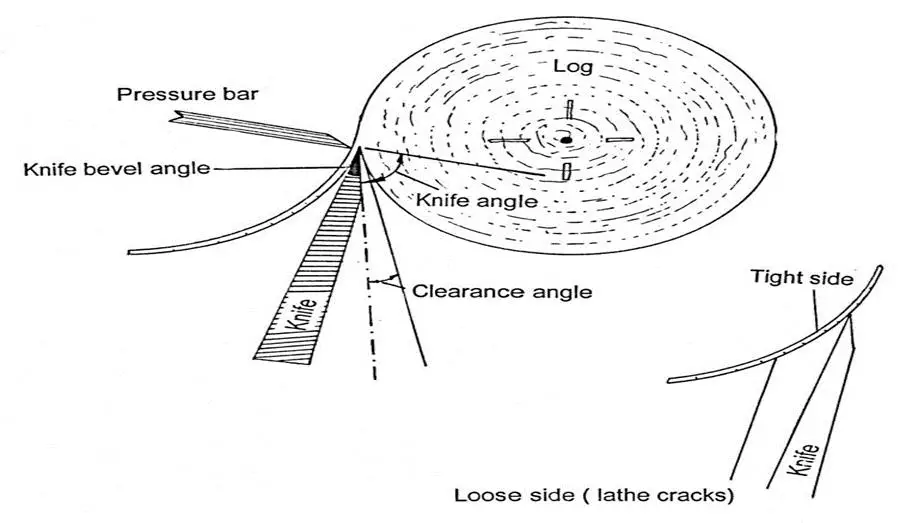

Rotary peeling is a method used to create veneer sheets that range in thickness from 2.5 mm to 4.8 mm. For the manufacturing of LVL, a typical veneer thickness is 3.2 mm. The lathe used for the rotary peeling of the logs involves geometry and knife location as key manufacturing elements that affect the veneer’s quality. For effective peeling of softwood, the bevel angle of the chosen knife is, for instance, roughly 23 degrees.

Also Read: What is a Beam Bridge? – Definition – Examples – Facts

The veneer will continuously be peeled from the log with a consistent thickness and without any fractures due to the pressure bar exerts on the veneer’s surface. Schematics of a typical rotary peeling veneer manufacturer using a fixed-nose bar and knife are shown in Figure 1.

The loose side of the veneer is the side closest to the knife edge, while the tight side is the opposite. Due to lathe checks running perpendicular to the grain, the loose side of the veneer has several small fractures.

Depending on its diameter, a bolt, which is a short log, may require 5 to 10 seconds to peel before its core is drained and the charger is prepared for the subsequent cycle.

Jet tube dryers are used to clip continuous veneer sheets to a specific width and dry them to the desired moisture level.

The overall moisture content of the veneer is reduced to the desired level in the jet tube drier by blowing hot air over the surface of the veneer sheets, which causes moisture to be peeled off. Typically, it takes 10 to 13 minutes to get a 3 mm thick Douglas fir veneer’s moisture level down to 8 to 10%.

Difference Between LVL and plywood:

In general, the manufacturing of LVL is identical to that of structural plywood; however, the fundamental distinction between the two products is the grain orientation of each veneer. In the case of plywood, an odd number of veneers are built across each other, resulting in a product with improved mechanical capabilities as well as dimensional stability. Because each lamina in LVL is parallel to the board axis, it has similar qualities to solid lumber because more veneers are assembled along the longitudinal direction. During the clipping process, defects on each veneer are removed. Even if faults are left on each veneer sheet, the random distribution of such defects during veneer assembly will result in more homogeneous finished products with strength.

Also read: Glulam Beam – Advantages – Applications – Table (With Examples)

attributes equivalent to high-grade timber. After applying an external adhesive, often phenol formaldehyde, to the surface of each veneer sheet, they are joined and pressed at temperatures ranging from 250 to 450 degrees Fahrenheit.

LVL presses are longer than plywood presses. The press line might be batch-type or continuous-type. A batch-type press with one or more apertures is more efficient for producing shorter length LVL. Most mills, however, employ a continuous press line. Billets can be up to 6-feet broad and have a maximum transport length of 80 feet. Figures 4 and 5 depict a typical LVL manufacturing process diagram.

LVL Beam and Span Support:

The length of an LVL beam is governed by its width and depth. Laminated veneer timber is commonly available in widths or thicknesses of 1-3/4″, 3-1/2″, 5-1/4″, and 7″, as well as depths ranging from 5-1/2″ to 24″, including standard and nonstandard depths. The lengths typically run from 4′ to 48′, with increments of 4′ available. Furthermore, depending on the manufacturer, bespoke orders of up to 60′ or 80′ are possible.

Most construction supply stores stock 8′, 12′, and 16′ lengths and may obtain larger lengths as needed. The length is frequently determined by the manufacturer, with 80′ possible but 60′ or less being more usual owing to shipping constraints. Beams can be cut to length and notched or drilled on-site, and they can be double, triple, or quadruple for strength and flexibility purposes.

The span of a beam is determined by its depth, breadth, and typical construction factors including building width, loads, number of stories, joist spacing, etc. It matters whether the span is many or single. Depending on its intended function, it may be a floor beam, joist, rafter, ridge beam, header, or lintel.

Also Read: What is a flitch Beam? – Purpose – Benefits – Thickness (Know ALL)

LVL Beam Sizes

LVL beams are usually available in 1-3/4″, 3-1/2″, 5-1/4″, and 7″ widths. Laminated beam depths range from 5-1/2″ to 24″, corresponding to 1-3/4″ The widths are 26, 28, 210, and 212 and are suitable for use with standard construction fasteners. Laminated timber is normally sold in 4-foot increments starting at 4′ and continuing up to 44′ or 48′ in length.

Some manufacturers produce LVL up to 60′ in length and some up to 80′, but owing to shipping restrictions, most keep to 60′. Many homes construction supply retailers’ stock 1-3/4 width LVL wood beams in 4′, 8′, 12′, and 16′ lengths for residential usage, and will custom order others as needed.

- Standard thickness – varies from 1-3/4” to 3-1/2”

- Span or length of beam – available in 24-ft, 28-ft, 32-ft, 36-ft, 40-ft, and 44-ft (largest available is 60-ft)

- Depth of LVL beam – typical depth varies from 5-1/2” to 24” (common depths are 7-1/4”, 9-1/4”, 9-1/2”, 11-1/4”, 11-7/8”, 14”, 16”, 18” up to 23-7/8”.

Size Calculation – How to determine what size of LVL beam I need?

Measure from the center of the support posts at either end of where the beam will be positioned to determine the length of the LVL beam necessary. Each manufacturer either offers span charts for their LVL products depending on various construction criteria, or they do not. Select the proper span table for one or two floors, and determine the distance to span, the depth and breadth of the beam, the span carried by the beam, and the live or total load for a floor beam.

For Example, we select a span of 20 feet and carrying a span of 40 feet, with a total load of 55 PSF for 100% load duration, which must be 5-1/4″ wide and 18″ deep, or 7″x16″. The beam might be a single-width or 3-4 layers thickness of 1-3/4” wide lengths.

To determine the depth of the beam you should use; here’s a simple thumb rule using span of beam:

“the depth of the LVL beam should be equal to the span in inches divided by 20”

For the width of the beam; here’s the rule of thumb:

“the width of the LVL beam should be ¼ or ¼ of the depth”

LVL Beam Size Calculator

Let’s suppose you’ve got the span for your building that you want to use an LVL beam but don’t know about the right size to choose. But don’t worry by using our LVL beam calculator; you can just enter the span in feet and the calculator will give you the right size of LVL beam. This calculator will give you the depth and thickness of the LVL beam you require based on the span:

Enter the span of the LVL beam in feet:

Size of LVL Beam

Depth of LVL Beam:

Width of LVL Beam:

LVL Span Calculator

Are you wondering how far can you span a 24-ft LVL beam? If so, here’s a LVL span calculator that will help you in giving the right span an LVL beam can go far.

Just enter the size of the LVL beam and it will give you the span:

Enter the depth of the LVL beam in inches:

Span of LVL Beam:

Here is a span table for the most common sizes of LVL beams:

| Size (inches) | Size (mm) | Span (ft) | Span (m) |

|---|---|---|---|

| 5-1/2 | 140 | 9 | 2.74 |

| 7-1/4 | 184 | 10 | 3.05 |

| 9-1/4 | 235 | 12 | 3.66 |

| 9-1/2 | 241 | 12 | 3.66 |

| 11-1/4 | 286 | 13 | 3.96 |

| 11-7/8 | 302 | 14 | 4.27 |

| 14 | 356 | 16 | 4.88 |

| 16 | 406 | 18 | 5.49 |

| 18 | 457 | 20 | 6.10 |

| 18-3/4 | 476 | 20 | 6.10 |

| 20 | 508 | 21 | 6.40 |

| 23-7/8 | 606 | 24 | 7.32 |

This table shows the size of the LVL beam in inches and millimeters, as well as the maximum span that the beam can support in feet and meters. The span is based on a load-bearing capacity of 1,360 pounds per square foot and a deflection limit of L/360.

Note that this table is just a rough guide and that the actual span of an LVL beam may vary depending on the specific conditions of your project. You should always consult a structural engineer or the manufacturer's documentation for more accurate span information.

Usage of LVL Beam:

LVL beams can be utilized as floor and ridge beams, joists, headers, lintels, rafters, trusses, rim boards, and scaffold planks for a range of structural framing and construction applications.

In addition to its many other applications, laminated timber is also utilized for ramps, truck bed decking, I-joist flange wood, and road signposts.

Although H3 and other chemically treated laminated boards may be used outside and exposed to a variety of weather conditions, the majority of LVL lumber is for dry indoor usage.

Further Read: Difference between load bearing vs. non load bearing wall

Cost of LVL Beam

The typical costs for LVL beams vary widely based on factors such as the location, supplier, and demand. Anyhow, the cost of an LVL beam may depend on the specific size, grade, and species of the lumber used, as well as any additional features or treatments applied to the beam.

Here is an example of a table that lists some common sizes of LVL beams and their approximate costs:

| Size | Approximate Cost per foot Installed |

|---|---|

| 5-1/2 inches | $50 - $75 |

| 7-1/4 inches | $75 - $100 |

| 9-1/4 inches | $100 - $125 |

| 9-1/2 inches | $100 - $125 |

| 11-1/4 inches | $125 - $150 |

| 11-7/8 inches | $125 - $150 |

| 14 inches | $150 - $200 |

| 16 inches | $200 - $250 |

| 18 inches | $250 - $300 |

| 18-3/4 inches | $250 - $300 |

| 20 inches | $300 - $350 |

| 23-7/8 inches | $350 - $400 |

This table is intended only as a rough estimate of the typical cost of LVL beams.

LVL beam Cost Calculator

If you're interested to find the cost of the LVL beam; this lvl beam cost calculator will be a great help.