So, while you’re looking to undertake a timber framing project, you got number of choices from LVL, Solid wood beam, Steel, and Glulam beam. But what are glulam beams and what exactly are they used for?

Well, if you’re new to wood framing, you might not know what glulam is.

Glulam is a short form of “glue-laminated-timber” (Glu-Lam). It’s an engineered wood that is made with layers of solid wood put together using high-strength adhesives making one structural unit. There’re number of types of laminated beams or laminated wood materials – Builders consider all such timber products under the name “glulam beams or glulams”.

What is glulam beam?

Glulam beam is an engineered wooden beam that consists of multiple layers of solid wood laminations put together with strong adhesives. The wooden laminations or lams are bonded together with glue that is industrial adhesives. Hence, they’re named as “Glu”+ “lam” as Glulam.

Also Read: Ridge beam – Size – Definition – Span – Span Table – Calculator

Glulam Beam Basics

Glulam beams are designed to cater for typical beam stresses – including flexural and compressive stresses. They’re engineered wood products (EWP) that are made with emphasis for efficient use of lumber corresponding to stresses. We use high-grade lumber along zones of maximum stress and low-grade lumber along zones of low-stresses of the beam. So, the strongest lam will typically go along the bottom and top of the beam to take care of the maximum compressive and tensile stresses.

Such efficient use of lumber make glulam beam as a versatile and innovative construction material. It is widely used these days both for commercial as well as residential timber projects.

Also Read: Bond beam in masonry walls – Design – Size – Foundation – Pros & Cons

Sizes and Grades

Depending on the type of application, different sizes of glulam beams are available in the market. You can buy custom and stock sizes both. Three common categories of glulam beam are suitable for premium, architectural, industrial, or framing. This classification is based upon the appearance of glulam beam and has nothing to do with its strength.

The most common sizes of glulam beam available for residential construction projects include 3-1/8, 3-1/2, 5-1/8, 5-1/2, 6-3/4 and 7 inches (representing the width of the glulam beam). But for most commercial and industrial applications, custom sizes can be easily made. You can design glulam beam for any longer spans, heavy loading, and other design circumstances.

As per the American National Standards Institute (ANSI) A190.1 (2017s), glulam material comes in four different grades related to their appearance as:

Also Read: What is a flitch Beam? – Purpose – Benefits – Thickness (Know ALL)

Framing

For typical house construction and residential framing projects, framing appearance glulam grade is a common choice. It is specified with dimension lumber and is only recommended for concealed areas that will be later covered with drywall or other suitable finishing product. Framing grade glulam beams have a width to fit flush with framing of wall 2×4 and 2×6. The framing grade has more irregularities than the architectural grade.

Industrial

Industrial grade glulam can have imperfections on the surface. Hence, this classification is only used for applications where appearance is not a primary concern. It can have loose knots and knot holes along the wide face of laminations but you can fill that with putty. Anyhow, the finish of industrial grade glulam is better than for the framing grade. You should use industrial grade for areas that’s not visible for general public.

Architectural

As the name implies, this grade of glulam is ideal for applications where beam will remain visible to people. So, the any holes or voids larger than ¾” are filled and covered. Manufacturers repair the laminations for any holes and defects using inserts and wooden fillers. All exposes faces are sanded for smooth finish.

Premium

Being at the top of the appearance grade classification, it is bit costly in comparison to other grade of glulam. Anyhow, premium offers the high quality of appearance and is only used for specific design application. Manufacturers minimize the visible knots and voids on laminations and all exposed surfaces are finishes properly.

Prices

The price of glulam beam depends on the beam timber species, section size as well as the span or length in meters. The typical price for glulam beam for residential grade is in range from $20 to $30 per feet of length. However, for industrial grade and high-strength applications the average price of glulam is from $30 to $60 per liner foot of span.

So, a typical glulam beam of 3-1/8 inch size for a 16 feet span will cost you around $320 to $480 per piece. But remember the cost range is typical and can vary depending on your location, and type of wooden species for the glulam pieces.

Also Read: What is Spandrel Beam? Uses – Design – Images – Wall – Vs Girder

Advantages of Glulam Beam

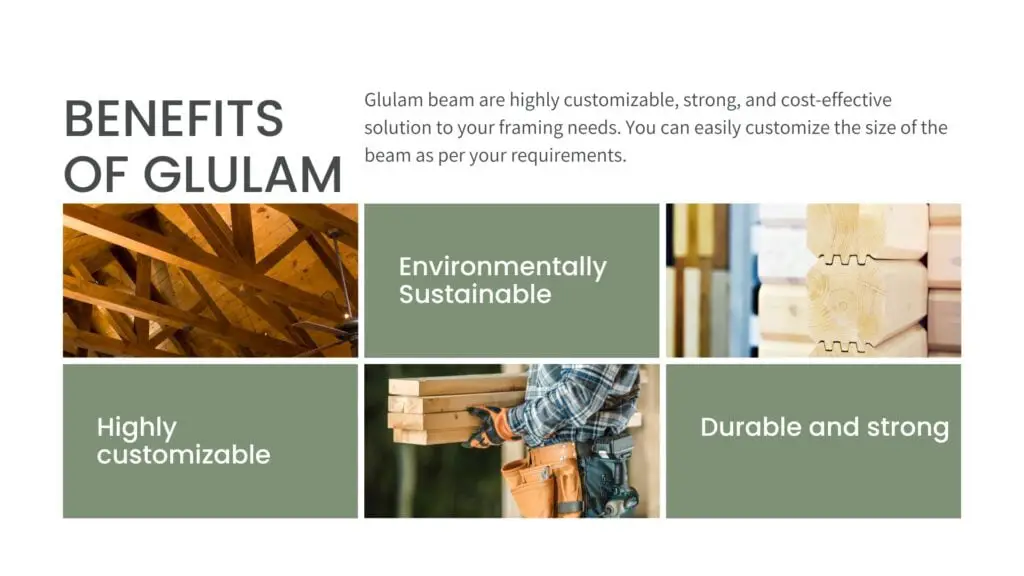

Glulam beam are highly customizable, strong, and cost-effective solution to your framing needs. You can easily customize the size of the beam as per your requirements. Moreover, they’re resource-efficient as they’re manufactured by using small pieces of lumber instead of large, old-grown timber. Here’re some pros of using glulam beams for your project:

- As they’re easily customizable, they’re perfect for long span and curved designs. The process of lamination makes it inherently flexible and you can have any size and complex shape of glulam.

- They offer strength without compromising the aesthetics. Homeowners prefer glulam against steel or concrete owing the warm and comfortable feel.

- It is an environmentally sustainable material, since timber grows off the ground and there’s no mining or high energy manufacturing involved.

- Since timber offers excellent strength-to-weight ratio, the construction process with glulam beam is pretty easy and fast. It makes your project easy to build. Unlike concrete or steel, you can use glulam beam easily for a roof space, large scale project, or making a prefabricated element. Moreover, it considerably reduces the dead load on the foundation. Hence, you need smaller foundations for your structure of same size.

- With modern technologies, you can use high-quality glue and preservative to enhance the durability of glulam beam. You can even use glulam for onerous of conditions like in swimming pool structures. It’s a low maintenance and durable solution even in highly corrosive environment where there’re high levels of humidity and chlorine.

- Unlike steel that deforms in fire, large section of glulam beam outperforms in fires. You can design glulam members that can last a certain period of time in fires.

- Solid timber beams and posts can crack of twist due to reduced stability in long-term applications. However, glulam beams can remain stable for many years because of high strength and dimensional stability.

Treated glulam beam span

A lot of homeowners are asking for how far can a glulam beam span? Well, glulam beams can easily span a typical space in residential applications. The ability of the beam to span a certain length depends on the depth, strength of timber specie, and treatment. Anyhow, a typical glulam beam can span up to more than 100 feet. To span more length, you can use engineered floor truss or similar product.

Treated glulam beams are in light honey color finish and are used for above ground exterior applications. They’re more common in raised deck beam applications. They are made by pressure treating with Hi-Clear II that’s a typical industrial wood preservative.

What is stronger Glulam beam or LVL beam?

LVL is made by sticking thin veneers typically 3 mm to form large structural members. Glulam, on the other hand, is made by using thicker sections of timber (around 15 to 45 mm thick). Anyhow, both LVL and Glulam are stronger in their own roles.

So, there’s no sure-short answer about their comparative strength. It depends on the manufacturing and role of use in type of construction projects.

However, homeowners prefer glulam as they’re easily customizable and are sanded, stained, and finished. LVL on the other hand is preferred only in concealed applications like over windows and doors as a beam. Even if you use LVL for exterior decks; you’ve got cover it up with a suitable finishing product.

Also Read: What is plinth Beam? – Purpose – Application – Types

Glulam Vs Steel

If you compare steel vs glulam on the basis of strength-to-weight ratio, glulam is 3 times stronger than steel. That means if you take two same sizes of beams – one is glulam and other is steel – glulam will offer more strength in comparison to its over-all weight.

With steel beams and sections in framing of a house; you not only have more dead-load for the sections to design but you also need bigger foundations to take the loading. On the other hand, glulam offers strength with light-weight members and small size foundations.

Glulam beam Vs solid Wood beam

Although most timber framing structures use both glulam and solid wood beams. However, there can be a time when you’ve got to decide one from the two.

Your decision between the two will be based on your preference around cost, design, and aesthetics. You should go with glulam when preparing complex designs with long spans and open spaces with no beams interrupting the flow of the space. However, glulam may cost you more and in some cases the aesthetic value of solid-wood beam will be more than the typical glulam beams. Glulam offers more strength than the solid sawn lumber along with far less warping and extraordinary durability.

Further Read: What is Pakkawood? Composition – Products – Properties [2021 updated]