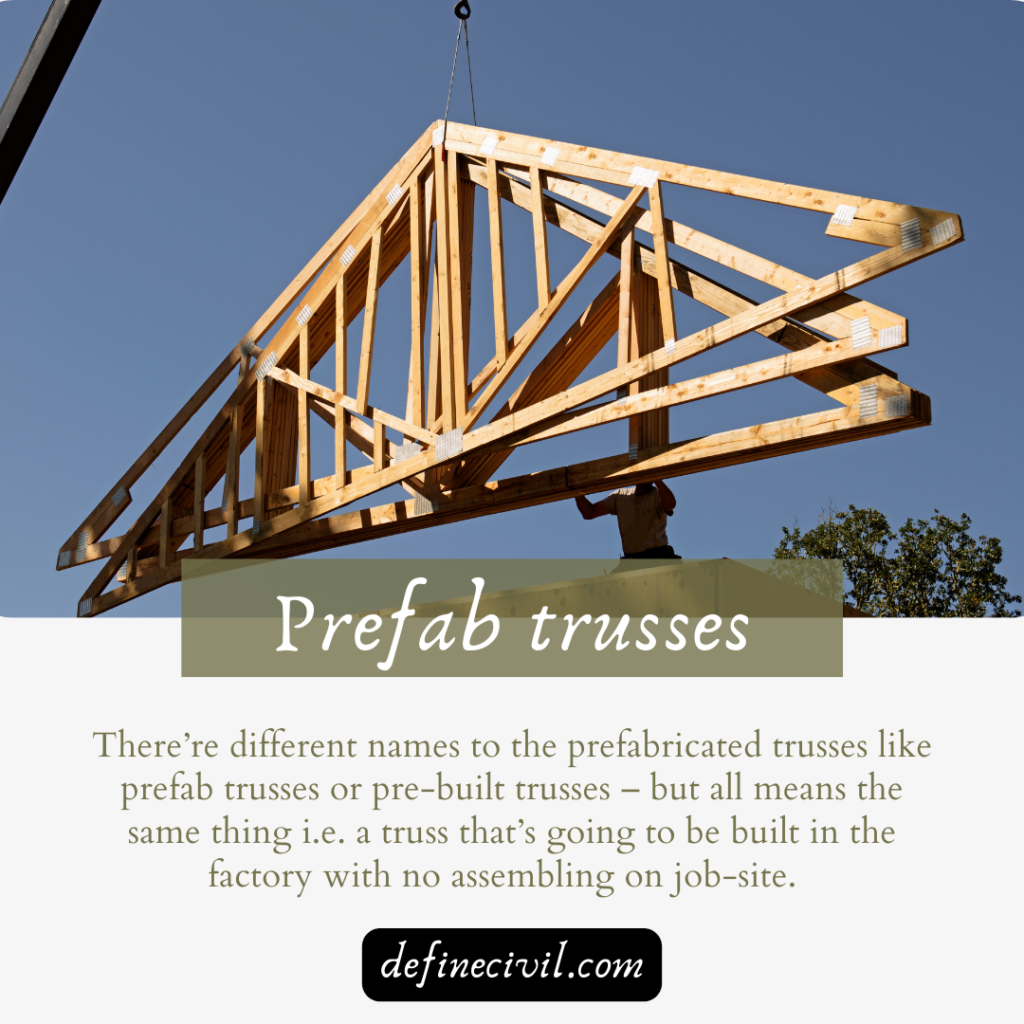

Nowadays a lot of homeowners are deciding to get prefab trusses or prefabricated trusses during new roof or roofing replacement. That’s probably because of the cost and the convenience. These types of trusses allow general contractor to maintain superior speed and precision during erection of complicated roof and ceiling designs.

There’re different names to the prefabricated trusses like prefab trusses or pre-built trusses – but all means the same thing i.e. a truss that’s going to be built in the factory with no assembling on job-site.

A roof truss is a prefabricated structure usually of triangles which is designed to support the roof covering or ceiling over rooms of building. There are two main types of trusses flat and pitched.

Trusses are further sub divided into different types and specific roof truss is selected on the basis of span length of building, loading conditions and suitability of truss for that roof construction. The prefabricated trusses are made in factories and then transferred to site and place after construction of building walls.

Trusses are normally made triangular in shape and these triangular shapes will in various configurations to fit the pitch, design of ceiling and size. Triangle shape of trusses is very efficient for finite control of load that’s why they are preferred in construction.

A truss has to support the weight of ceiling so it should be strong and stable, and all these features are available in triangular shaped trusses.

Parts of prefab roof trusses

A roof truss consists of following main parts

- Top chord – Roof sheathing goes on top of this member.

- Bottom chord – Your finished ceiling is mounted on the bottom chord.

- Bearing point – The location where the outside bearing wall gets beneath the truss.

- Metal Gussets – It’s the joint where web support and king post overlap the top and bottom chord.

- King Post – The top of the common truss highest support is the king post.

- Web support –

Types of roof trusses

Mono Truss

A mono truss is right angle triangle shaped truss which is used for verandah or shed covering support. It consists of single common rafter only and is the simplest type of truss. You can also find it by names like Pent or Aisle Roof. It is suitable for maximum span of 2.4m.

Raised tie truss

Raised tie trusses are triangular shaped trusses which are used to provide a higher ceiling line for extra headroom. It is suitable for increasing the height of room without increasing the height of building.

Scissor Truss

The scissor type truss is also used in construction, and it forms vaulted ceiling. It is similar to raised tie truss but only difference is that it has lower member sloping which give more strength to a truss structure. They are not recommended for installation on load bearing beams or walls.

Pratt Truss

A Pratt truss consists of vertical, horizontal and diagonal members. The load distribution in such a way that vertical members are in compression and diagonal members are in tension. The Pratt truss has been in use over century because of its effective truss application. The cost of construction of this truss is less due to high efficiency of members.it also reduces self-weight and construction of this type of truss is easy. This type of truss is suitable for horizontal spans like railway bridges where loads are in vertical direction.

Warren Truss

Another type of popular truss is warren truss which consists of horizontal, vertical and inclined members. This truss has its inclined member in such a way that it forms an equilateral triangle. The benefit of warren truss is that it distributes the load of the structure evenly on different members due to its equilateral shape. This type of truss is suitable for structure where we want to distribute the load uniformly. But it is not preferred for structures where there are concentrated or point loads.

King Post Truss

This type of truss is also used for supporting building roof. It is triangular in shape with vertical post at its center which is known as king post. King post is used to support tie beam. It also consists of inclined members called strut which prevent the principal rafter from bending. It is used for building spans between 5-8m.

Queen post Truss

A Queen post truss is used for roof covering. The main difference between king post and queen post truss is that queen post truss consists of two vertical posts. Queen post truss is used for span length of 8-12m.It is more suitable for structures where loads are heavy and span length is large.

Mansard Truss

A mansard truss is a combination of both king post and queen post truss. Mansard truss consists of two portion the upper portion consists of king post truss and lower portion consists of queen post truss. This truss is also used depending upon the loading condition and suitability of building roof construction.

Gambrel Roof truss

Gambrel roof is widely used for construction purposes due to its wide applications. A gambrel roof consists of horizontal, vertical and inclined members. There are two different slopes in gambrel roof. From center of span the sloped members move in opposite direction and the second sloping member is steeper that first one. Due to outward-protruding shape, these trusses are effective to be fitted with a hollow center, which is used as a storage area. The upper portion of barn is in gambrel shape that’s why it is called Gambrel roof truss.

Bow String truss

This type of truss is also used for buildings and bridges but less often used in factories or industrial roofs. It is also known as bel fast roof truss or latticed roof truss. The name is given to this truss because it is the form of bow. It consists of these sections of timber with its top chord curved. This type of truss is like an arch shape. This type of truss is suitable for span of 30m where light roof covering is used.

Benefits of Prefabricated Trusses

- The prefabricated timber trusses are made and assembled in factory and simply installed on site without on-site hassle.

- Timber trusses are lightweight which saves a lot of time, energy and backbreaking labor on behalf of contractor.

- Trusses are made in factories which reduces the chances of accidents on construction site.

- A prefabricated timber trusses are stable, resilient and more durable.

- Trusses are available in different span lengths and size according to requirement, loads and suitability of truss for roof covering and supporting purposes.

Are prefab trusses cheaper?

Yes, overall the prefab trusses are cheaper because fewer carpenters are enough to undertake the job. Moreover, the time period for a new roof or a roof replacement reduces considerably; since you don’t have to erect the roof trusses from the scratch. Unlike traditional roof framing, prefabricated trusses are the choice of modern builders and contractors.

How much are pre built trusses?

The average cost of a pre-built roof truss is around $100 to $300 for one piece. But this cost depends on a lot of factors like the type of truss, span, material, durability, and different features. A 30 ft prefab roof truss may cost you around $250 to $300 with a typical pitch of 5/12. By material, wooden trusses are cheapest in comparison to steel trusses. Wooden prefab trusses cost you between $35 to $350 whereas the steel trusses are between $150 to $600.

How many trusses do I need?

For a 40 ft roof span, you’ll probably need 20 trusses. To determine the number of trusses you can multiply the span (length of roof) with 12 and divide it by the span of one truss. So, for example, the span for truss distance is 2 feet; the truss count will be:

Truss count for 40 feet roof = ((40 x 12) / 24)+1=20 nos.