So, there’s a lot more confusion going on out there about the difference between development length and lap length also known as splice length. With that, I thought I should give my words about the two very important and basic concepts of structural engineering and construction.

To understand why there is a need to provide development length and splice length across the rebars; you’ve got to have some overview on how rebars actually transfer or take stresses to or from the adjoining concrete mass.

How rebars transfer stresses to adjacent concrete section?

Reinforcement bars take up the tensile stresses from tensioned zones that are transferred by concrete matrix by using bond resistance.

[su_note note_color=”#ff7366″]If the bond between the two types of material is not at par with the induced stresses the structure may fail in brittle which is too dangerous.[/su_note]

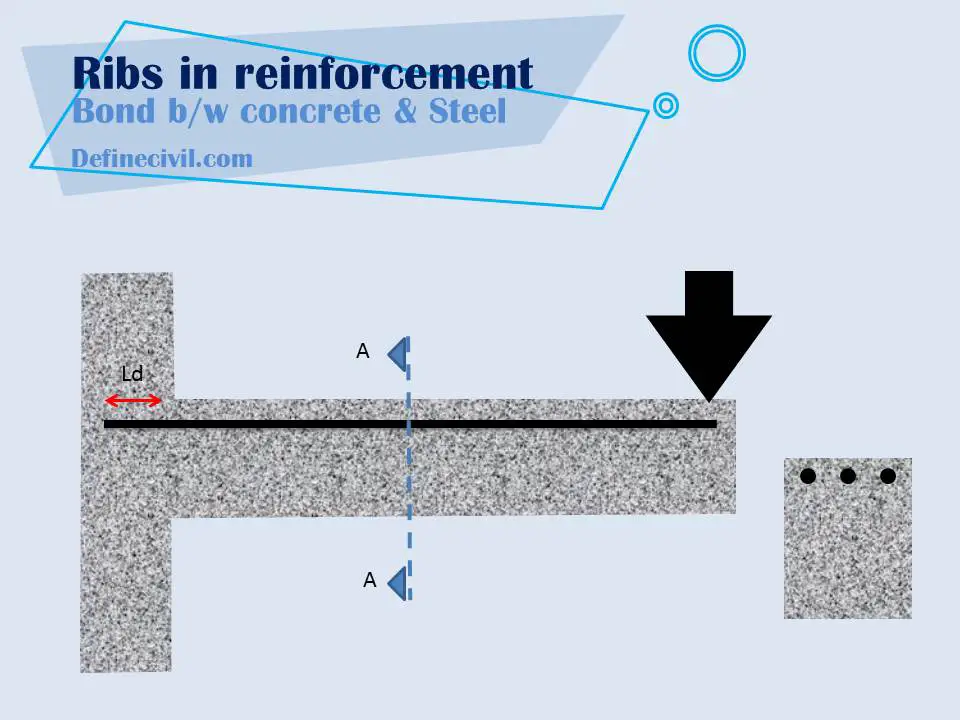

All reinforcements now have ribs across the perpendicular direction to provide some lateral restraint and anchorage against slippage bond failure.

[su_service title=”Important to Note” icon=”icon: legal” icon_color=”#2128cd”]These ribs account for about 85% of the bond strength while only 15% depends on the friction between steel and concrete.[/su_service]

[su_service title=”Important to Note” icon=”icon: podcast” icon_color=”#2128cd”]With above you might think that plain rebars have no application so why are those factories still producing them? Actually these plain smooth rebars are still used while doweling two adjacent concrete slabs when you need an expansion or contraction joint. One end of the dowel is greased and caped while the other one is embedded to allow slippage in case of expansion and/or contraction.[/su_service]

Now that you’ve got the background why it is so important for the rebars to have proper anchorage in the concrete matrix; let’s move on to our core issue which is about development length.

Why there’s a need for development length of rebars?

In buildings we have various elements of structure like a column and beam. If you have an overview of load transfer mechanism you would have picture in your mind how the imposed load (dead and live) is transferred from slab to beams from beams to columns and from columns to footing.

Now to transfer tensile stresses from element of structure to other you just can’t terminate the reinforcement at the end of the element i.e. you must have to develop and project the main reinforcement into the adjacent section to have those tensile stresses transferred efficiently.

The fixed end restraint in an element like in beams – you have to provide this development to provide resistance against induced bending moment. But in cases where you have the hinge or roller restraint you don’t have to provide this development.

Have a look at the below cantilever beam; we know the tensile stresses are maximum at the supporting end but we have to project these bars in to the supporting column for transferring the tensile stresses across.

So the rebars are projected and extended into the supporting column by a distance Ld called development length to make beam and column monolithic.

What is development Length?

Now, we can define the development length as:

The extended certain minimum length of reinforcement bars across the two different elements of a structure across the point of maximum tensile stresses to establish the desired bond strength and make them monolithic without slip or to prevent bar from pulling out under tension is called development length. It is usually denoted by the nomenclature Ld.

How to Calculate Development Length?

Development length of rebar depends on following factors:

- Diameter of rebar

- Design bond stresses

- Tensile stresses in bar at the section considered at design load.

So we can calculate the value of development length by the following formula:

[su_note]Ld = ɸϬs / 4Ϯbd[/su_note]

Where

ɸ = nominal diameter of the rebar

Ϭs = stress in bar at the section considered at design load, and

Ϯbd = design bond stress

For places where straight development length is not possible, hooks, bends and mechanical anchorages can be provided to have proper anchorage.

The design bond stresses depends on the concrete grade and type of rebar whether plain or deformed bar. So as a guide I’ve produced these tables. This design bond stress are different for limit state design method and for working stress method as reproduced below:

[su_table responsive=”yes”]

| Design Bond Stress in Limit State Method | ||||||

| M20 | M25 | M30 | M35 | M40 and above | – | |

| Concrete Grade | 1.2 | 1.4 | 1.5 | 1.7 | 1.9 | For Plain Bars in Tension |

| Design Bond Stress (Ϯbd,N/mm2) | 1.92 | 2.24 | 2.4 | 2.72 | 3.04 | For deformed bars in tension |

[/su_table]

[su_table responsive=”yes”]

| Design Bond Stress in Working Stress Method | ||||||||

| – | M20 | M25 | M30 | M35 | M40 | M45 | M50 | – |

| Concrete Grade | 0.8 | 0.9 | 1 | 1.1 | 1.2 | 1.3 | 1.4 | For Plain Bars in tension |

| Design Bond Stress (Ϯbd N/mm2) | 1.28 | 1.44 | 1.6 | 1.76 | 1.92 | 2.08 | 2.24 | For deformed bars in tension |

[/su_table]

What is the difference between lap length and development length?

In factories all over the world, the standard length produced of a rebar is 12 meters (39 feet). So if you have a pile foundation of 30 meters you have to provide lap or rebars to transfer tensile forces from one rebar to the other.

So, lap length also known as splice length, is the length of the rebar that is overlapped so that the tensile forces can be transferred across the location of discontinuity of rebars. So from definition it is quite clear that development length is across the section of structure or element whereas the lap or splice length is only across the location of discontinuity of rebars.

[su_service title=”Answer if you’re a Genius!” icon=”icon: podcast” icon_color=”#2128cd”]Now that you know what is development length? what is Lap length? What is the difference between lap length and splice length? I’d rather leave you with a question which you’ve to answer (only if you are a genius) and the question is : What do you think that the Development and Splice length of coated rebars would be more or less? (coated rebars protected against corrosion)? Answer in the below comments; I am waiting. [/su_service]