When it comes to treating water in developing countries we mainly rely on two types of filtering system. One is slow sand filters and the other is rapid sand filters. The later on is also termed as rapid sand gravity filters or in short form as RSF (rapid sand filter). It is a low-cost filter that uses the concept of settling to clean water. It is also sometimes used in developed countries, if the need arise.

What is the purpose of rapid sand filter?

As the name implies, rapid sand filter uses sand and gravel to clean the water. But what actually makes it work so efficiently and how it compares with some other modern types of filter? So, in our today’s article; we’re going to explore all of these questions.

Let’s get started:

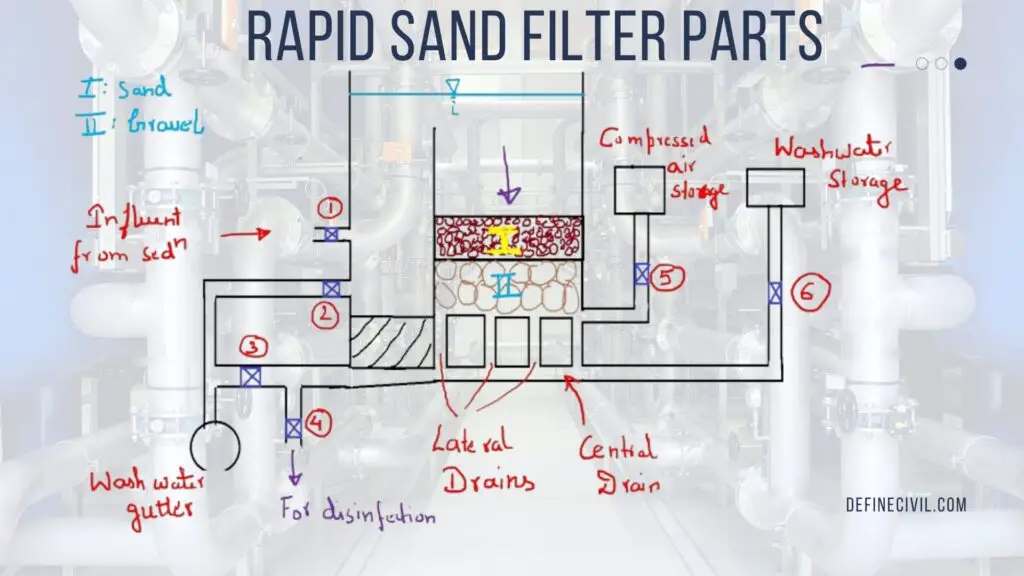

What is rapid sand filter? – The components

Rapid sand filters are made from four layer of materials: The first layer consists of coarse sand, followed by a layer of fine sand that acts as a filtration bed. A third layer called the underdrain or under drain contains coarse gravel that prevents particles in the filtration bed from floating to the top of the filter and clogging it. On top of this there’s an overflow pipe that drains out waste water into another tank.

Developing countries have always shortage of clean water. Moreover it is accessible only by traveling long distances over dangerous terrain. For such, rapid sand filters are very beneficial. They are easy to transport and install or setup. You can use this filter to purify drinking water from any source including lakes, ponds, and rivers that are full of weeds or debris. You can also purity water from microorganisms or other contaminants.

Enclosure tank

It is a typical tank that encloses every bit of thing we have for the rapid sand filter. It houses the filter media, the valves, the under drainage system, and the perforated pipe system. We normally prefer a depth of around 2.5 to 3.5 meters. You can construct the enclose tank from concrete or brick. But make sure to use the material that is readily available in your area.

Also Read: Turbidity Curtain -Arrangement -Structure – Installation

For a typical size filtration system, we recommend a plan size of 15 to 50 meter with length to breadth ratio of 1.25 to 1.35 meters. But be sure that the size of the tank has a direct impact on the filtration rate of your system. Usually we need a filtration rate of 3000 to 6000 liters per hour per meter square.

Filter media

As the name implies, for rapid sand filter the filter media must be sand. Yes, it consists of a sand layer in thickness of 600 to 750 mm. The effective size of the sand ranges from 0.45 to 0.75 mm. The uniformity coefficient of the sand or filter media varies like 1.3 to 1.7 but commonly it stays at 1.5. If you’re not sure of the uniformity coefficient, here’s a very good video by Ganesh.

Base material

When we speak of the base material, we are referring to the gravel that act as supports of the filter media. The gravel bed is typically 450 to 650 mm thick. Anyhow, it is graded and laid in different layers while each layer is 150 mm thick.

Under drainage system

I’ve already talked a bit about under drainage system in the introduction; so let’s now see what it really is.

Under drainage system or under drain helps collect the filtered water and gives a mechanism to provide uniform distribution of backwash water. Two common types of under drainage system are :

- pipe and strainer system

- Perforated pipe system

While perforated system is economical and simple in operation but it needs high velocity of water during backwashing the filters. Pipe and strainer system consists of series of lateral drains that are connect to a central drain. It consists of strainers on the holes in the lateral drains.

Appurtenances

Other components of the system include air compressor, valves, head loss measuring system, flow regular, and wash water trough.

Working of the system

To understand the working of the rapid sand filter; we’re going to see how it operates during normal condition and how we can undertake the backwashing.

Normal operation

During normal phase or working of the system, we only use two valves: inlet and outlet. The inlet valve takes the water from the raw water channel and sends it to sedimentation and coagulation. The next outlet valve delivers the filtered or treated water to the storage tank. From there it is supplied to the consumers.

Backwashing

When the head loss reaches around 2.5 to 3 meter, we recommend the backwashing or filter cleaning of the system. During normal circumstances, we recommend backwashing at the interval of 1 to 3 days. Although the backwashing typically takes only 10 to 15 minutes but you can expect a system disruption of about 50 minutes.

Anyhow, here’re some steps for backwashing the system:

- First close the inlet valve (valve-1) and let the water level lowers as it washes through water troughs.

- Now close the outlet valve as well. Open valve of the compressed air and wait for 2 to 3 minutes. The compressed air will break the scum, loose the dirt, and will push both in upward direction. Now close the valve of the compressed air and open the valve for wash water from the wash water storage tank.

- Now as the dirty water is in ready to dispose, open the valve towards the wash water gutter. It will remove the dirty water. Now after flushing, close the valve of the dirty water and let the material to settle to the surface of the sand.

- Now open the inlet valve slightly and valve of the filtered water storage tank for few minutes to allow fresh water to wash the water drain.

- Now you’re all done, close valve 5 and open valve 2. You can now operate the filter as per the normal procedure.

Rapid Sand Filter Efficiency and Speed

This type of water treatment system is typically very efficient, especially when it comes to maintenance. Here’re some factors that indicate its efficiency:

- Bacteria removal efficiency – 80 to 90 %

- Turbidity removal – 35 to 40 ppm

- Color removal of water – below 3 on the cobalt scale.

Since they’re relatively low-maintenance, they typically have lower operational costs than other methods. However, they also usually don’t work as quickly as other types of filters. But if you’re looking for something that’s cheap and effective over time, a rapid sand filter might be just what you need!

Unlike slow sand filters, rapid filters give you swift flows. You can expect to achieve a flow of between 4 – 21 m/h with rapid sand filter. This is around 20 and 50 times faster than the range of slow sand filtration.

Advantages

A rapid sand filter can be built from readily available parts, is easy to use and it works very well to reduce turbidity in water. It’s much more efficient than other types of filters and can remove up to 98% of suspended particles

Disadvantages

The equipment is not as efficient at removing heavy metals as slow sand filters. It also requires more regular maintenance and is more difficult to use. Rapid Sand Filters need high capital and operational costs that can further increase the need to pretreat raw water.

Moreover, high degree of training and experienced plant operates are must. The technology like use of energy for pumping and sophisticated system needs high capital and operational costs.