Stirrups in reinforcement of beam play a vital role in resisting shear stresses. During construction of buildings, civil engineers provide stirrups with the purpose to hold reinforcement in place and to prevent collapsing of the main reinforcement during seismic activity.

What is a stirrup in construction?

Closed loop bar provided at a regular center to center distance for holding the position of main reinforcement bars in beam and column is known as stirrups or lateral ties.

Difference between stirrup and ties

Both are same and their purpose of providing is also same. Only difference is the difference of their placement. When this closed loop bar is provided in a beam at a regular interval it is called as stirrup while when it is provided in column it is called as lateral tie.

Stirrups include mild steel bar that is usually of 5 to 8mm and provided in beam or column reinforcement to resist shear force and to obtain various objectives which are discussed in this article.

So, let’s get started:

Why are stirrups used?

There are various purposes of using stirrups in reinforcement work some of which are shown here:

- Main purpose of using stirrup is to hold the position of main reinforcement.

- Stirrups are also used to prevent structure from failure due to shear force as it provides shear resistant in reinforced structure.

- It prevents buckling and deformation of main bars.

- Stirrups provide resistant to lateral forces such as earthquake.

- Stirrups are provided to provide stability and keeping alignment of main bars.

- Stirrups are provided to control movement of main reinforcement bars while process of concreting.

- Stirrups also provided to increase compressive strength of beam or column and to increase their ductility.

Types of Stirrups:

Stirrups comes in all sizes of shapes, arrangements, and sizes. So, let’s see how can classify stirrups.

On the Basis of Shape

On the basis of dimensions and number of main reinforcements in a beam, stirrups are provided in different types of shape which includes:

Rectangular Stirrup

As the name suggests, these stirrups are used in rectangular beams. Their one dimension is shorter than the other and are mostly used in beams.

Square Stirrup

These are stirrups with both dimensions same and are used in square shaped beam or square shaped column.

Circular stirrup

Well, it is quite rare to see a square beam but columns are circular in many cases. So, we can say circular stirrups are common in columns.

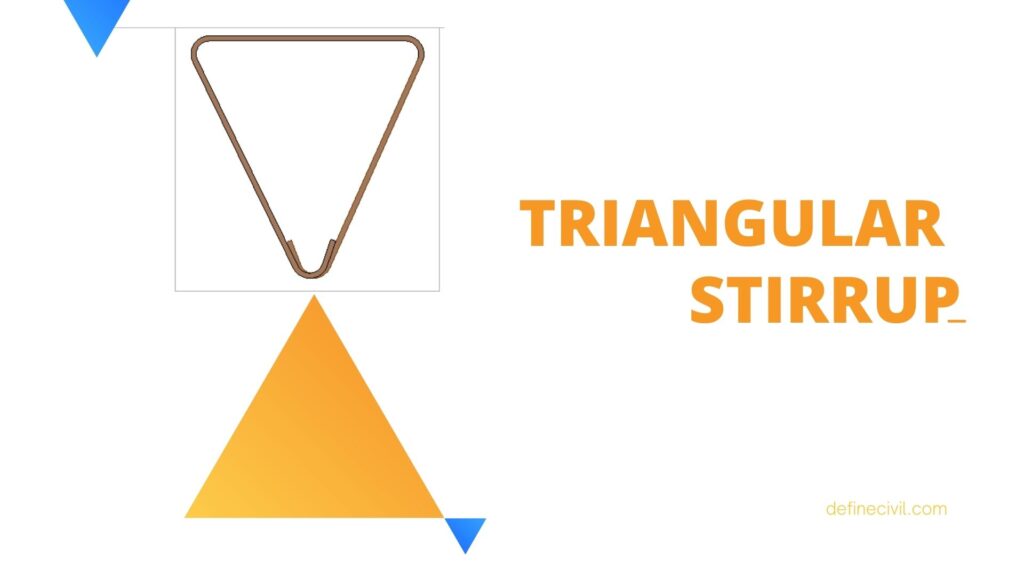

Triangular Stirrup

These stirrups are used in combination with other types of stirrups in beams.

Spiral Stirrup

These stirrups are provided in pile or columns.

On the basis of nature of Construction:

On the basis of nature of construction work, stirrups are divided in to following types.

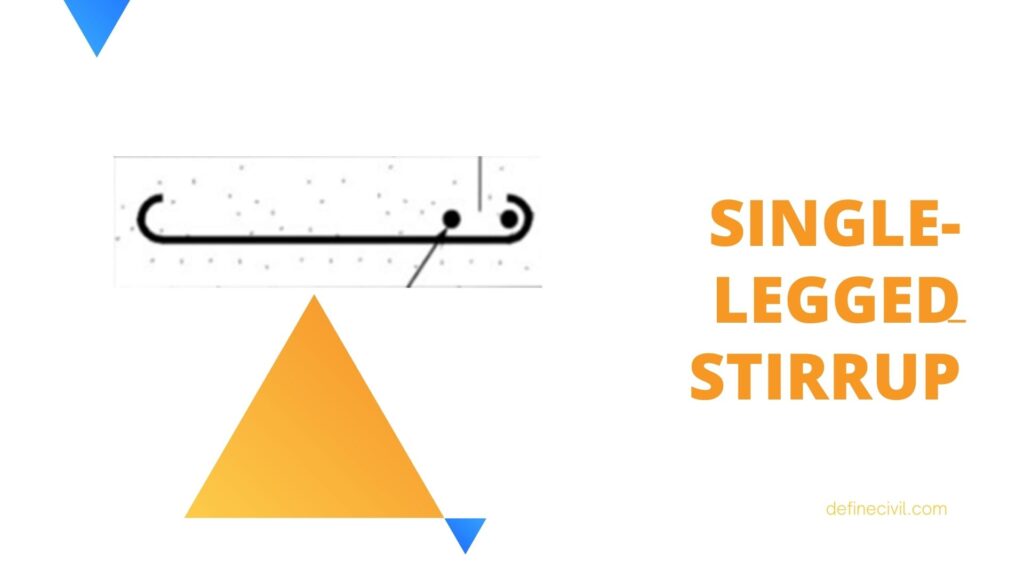

Single Legged Stirrup:

This is an open type of stirrup which is not widely use in construction while use only if there is a need to simply connect two rods. This type of stirrup does not have complete loop while has only flatten U-shaped form which helps to connect main reinforcement.

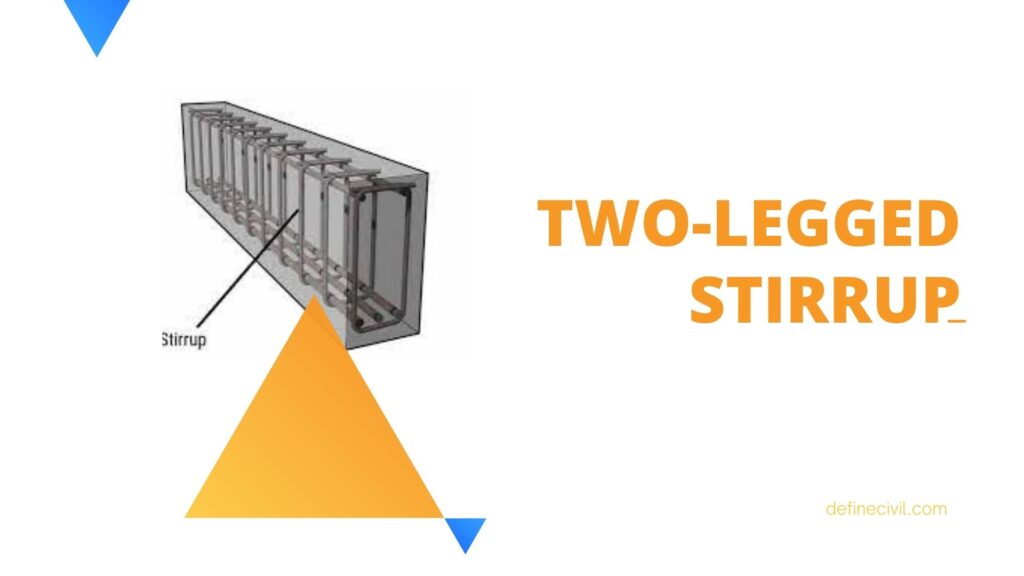

Two-Legged Stirrups

This is closed stirrup and most widely used in construction in these days. It requires four main reinforcement bars to get completed.

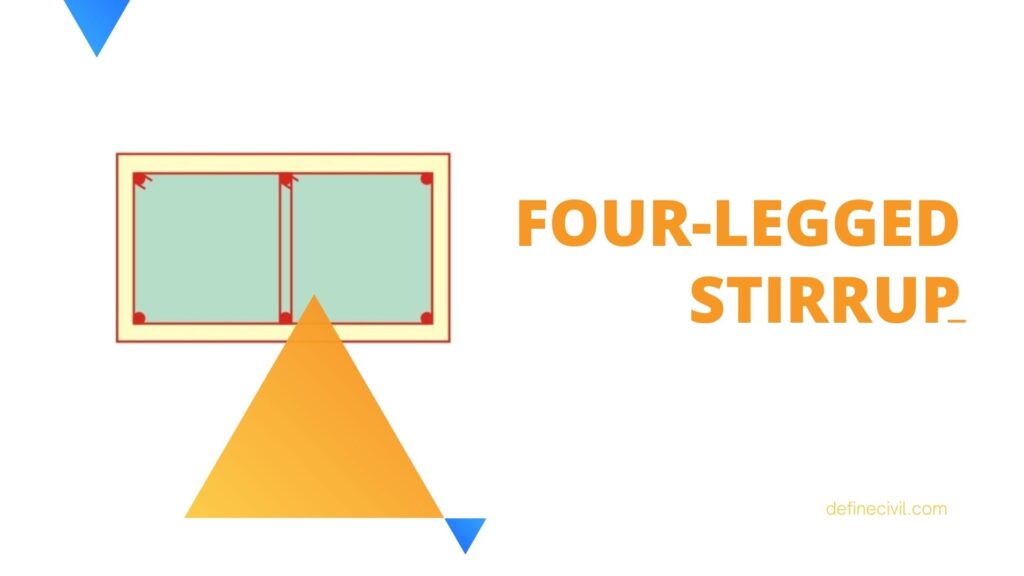

Four-Legged Stirrup:

This is also closed type stirrup which is of higher type and used in heavy reinforced structures. It is used for minimum 6 main reinforcement bars. This type of stirrup is form by overlapping two 2-legged stirrups. It is shown in figure below:

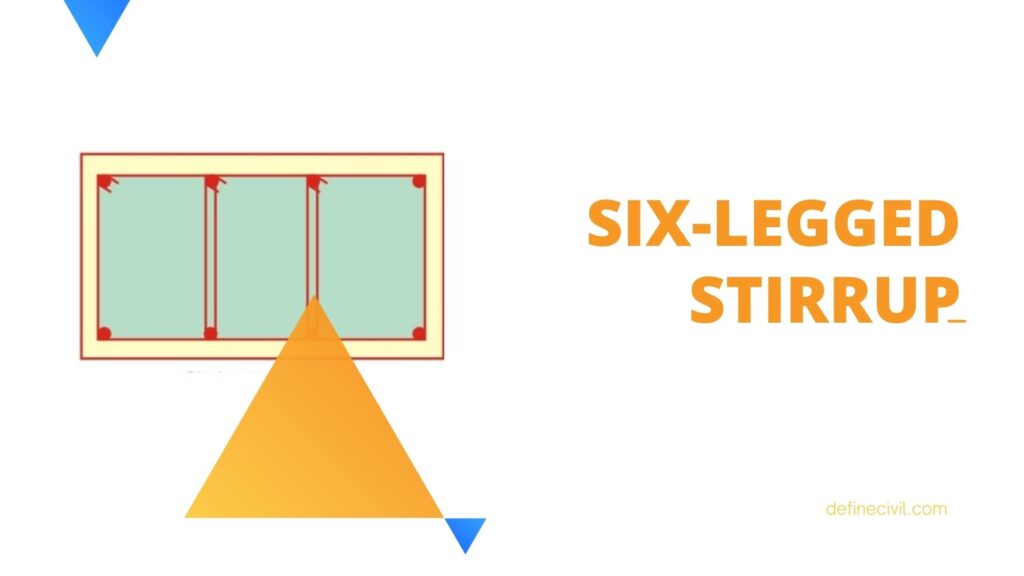

Six-Legged Stirrup:

This is also closed and higher type of stirrup which is used in heavy reinforced structures. It is formed by overlapping three two-legged stirrups. It is shown in figure below:

Types of Stirrups used in Columns:

Stirrups in column is known as ties or transverse reinforcement. On the basis of number of main reinforcement bars, loading conditions, and on varying cross-section, stirrups in columns are provided in two types that include:

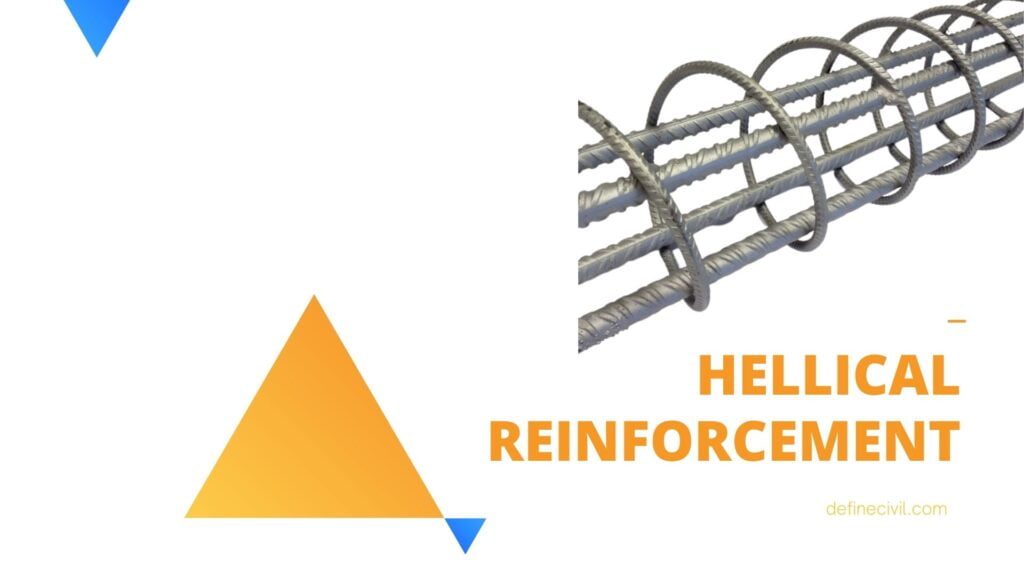

Helical Reinforcement:

In this type, stirrups are provided in helical shape which provided more ductility and flexibility to column structure which results in increase in efficiency of using helical reinforcement as compared to other ones. This type of stirrup also increases buckling resistance of column structures as compared to other ones. This type of stirrup is considered effect for bearing lateral loads and that’s why they are strongly recommended for seismic design. Therefore, helical reinforcement is better recommended to other rectangular or normal rings. This type of stirrup is shown below:

Lateral Ties:

It is a type of stirrup or tie which is use in columns and known as transverse reinforcement in column which is provided at regular spacing in column to provide support and stability to main bars and for shearing resistant. This type of stirrup is provided in rectangular close looped bar in the form of 2-legged stirrup, 4-legged stirrup, and 6-legged stirrup.

Also Read: What is a tie beam? – Details – Advantages Reinforcement – Design

Design Consideration of Stirrups:

Distance for stirrups:

- Center to center spacing of stirrups increases towards center and decreases towards support. Usually, it is provided at distance of 6 inches.

- Center to center spacing of stirrup should not be more than lever arm of resistant moment.

- Spacing of stirrups should not be more than 6 inches or 0.75d according to Indian Standard IS456.

Number of Stirrups:

Number of stirrups in a beam or column is find out by dividing length of bar to center to center distance of stirrups.

Cutting Length of Stirrup Bar:

Cutting Length of stirrup bar is founded by following step:

- Consider the dimension of beam or column.

- Take the diameter of stirrup bar usually it is 8mm.

- Subtract concrete cover or clear cover.

- Now find the length of stirrup.

- Add the length of hooks.

- Subtract the length of bend.

- Now consider following formula for finding stirrup cutting length.

Cutting length of stirrup=Perimeter of shape + Total hook length – Total bend length.

Hook Length of Stirrup:

Hook length of column is taken as 9d or 75mm.

Bend Length:

Following bend length is provided for different angles bend.

- 45 degrees bend = 1d

- 90 degrees bend = 2d

- 135 degrees bend = 3d

Conclusions:

Stirrups is the closed loop bar provided in beam or column to resist shear forces and provide stability to main reinforcement during concreting or other loading conditions on beam or column. These are provided in various shape like circular, rectangular and triangular on the basis of varying loading conditions of beams or column. These are also divided into 2-legged, 4-legged and 6-legged stirrups depending upon the way how they are employed during construction while connecting main reinforcement bars.