It would be interesting for you to know about top down construction; because the deepest in the world’s building is Jinping Laboratory, China mounting to 7,900 feet beneath a mountain. Almost everyone knows about the Empire State building to Burj Kalifa or likewise but only few knows the fact that race among masses is not just to go high but is to go deep as well.

Constructing deep structures vide traditional sequence i.e. bottom to top would require much of time for excavation. Thus making it a critical activity.

In such projects contractor is expectant to have hard time for kick-starting and streamlining the construction activities.

So a term has recently evolved, of a new approach, by expert engineers and constructors which is top down construction also known as up down construction.

So in this read we would be going through the definition, procedure, methodology as well as advantages of top down construction vs down top construction.

If you are familiar with all the gamesmanship of project management, you better know the significance of time and space as constraints in urban infrastructure projects.

The planning engineers know that for buildings the activity of foundation construction could not commence before excavation of the substructure. So in planning and scheduling excavation is meant to be predecessor of the foundation construction.

A perfect approach for a project manager would be to streamline construction activities in a manner that excavation of deep foundation and construction of superstructure could continue in analogous.

This would be saving considerable amount of money and reducing enormous pressure on the project timeline as well as milestones therein to be achieved.

But thanks to this top-down construction methodology you could turn the tables on. It has twofold plus in terms of supporting the excavated face of the ground by permanent structural elements as project progress downwards as well as saving time as described above.

By doing so, you don’t have to worry about the space needed for the spoil and because of the disturbance to the soils vide unsupported excavation in a congested urban unit of a city.

[su_box title=”Do you know?”]With the old construction technique, you can’t construct two or more Empire State Buildings close to each other because excavation for the second building would damage the foundation of the first building due to ground disturbance and stresses. [/su_box]

Top Down Construction Definition

A simple definition of top down construction procedure is that the basement floors or substructure of the buildings are constructed in a manner that after completion of ground floor first, the basement floors are built from top to bottom floor by floor.

Top Down Construction Procedure

Generally, the procedure adopted for top down construction is as follows: –

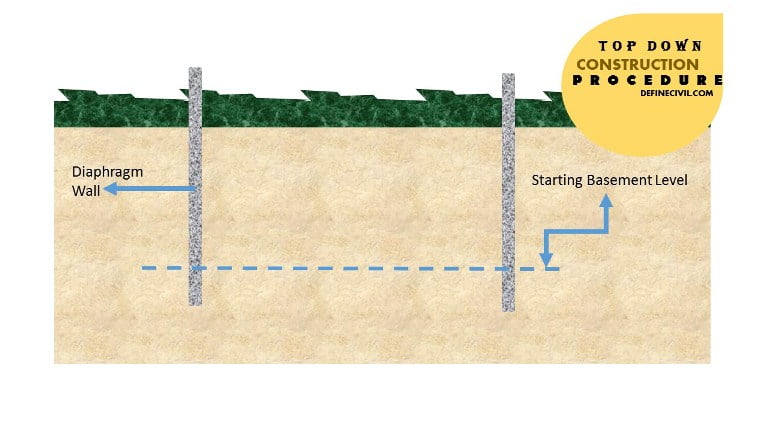

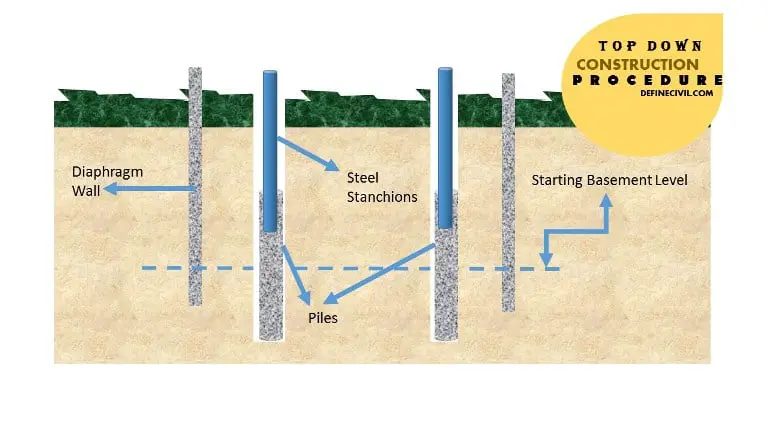

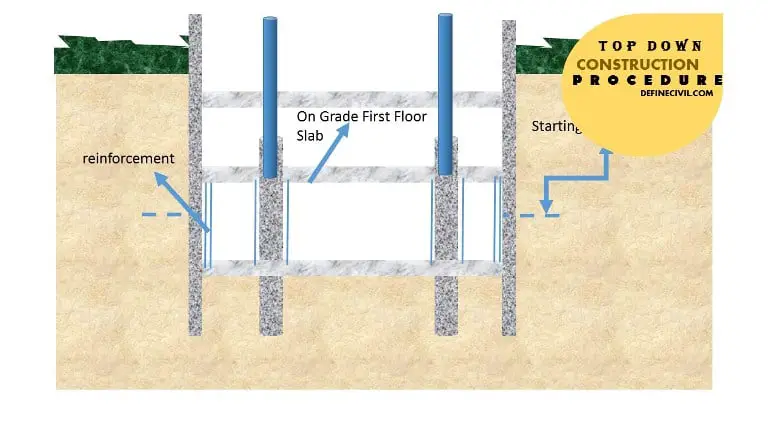

- Diaphragm walls or underground walls or also called cut-off walls, are first drilled and their foundation is casted. They can be sheet pile, pipe pile, soldier pile or diagram wall whatever is decided based on site conditions. Thickness and panel to panel distance of the wall depends on the type of soil and the amount of surcharge that is supposed to be supported. Usually 24” to 48” is general enough for normal conditions but it must be ensured that the wall has suffice embedment into the soil at full depth.

- For transferring the load of the building to hard bearing stratum, piles are drilled using auger boring or percussion boring depending on site situation. Before finishing the top 2 meters depth of pile; steel columns called stanchion are embedded below the pile cut off level.

- The Steel columns would be supporting the load of the superstructure and they must be strong to sustain imposed load during the construction time. The ground floor base slab is usually of more thickness then all other floors slab and they act as lateral supports for the columns as well as the diaphragm walls.

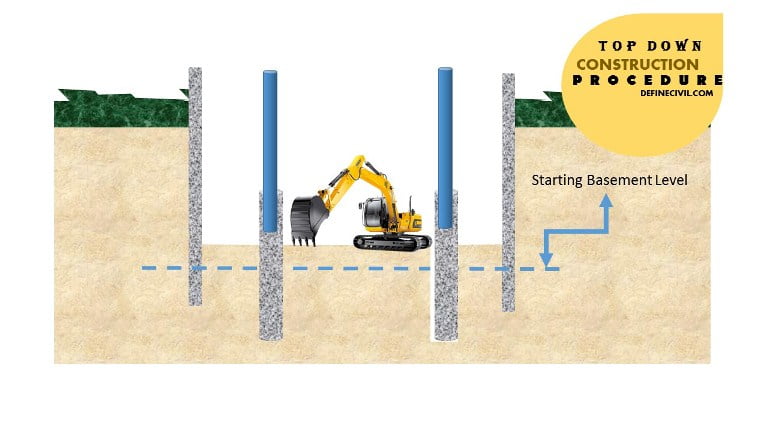

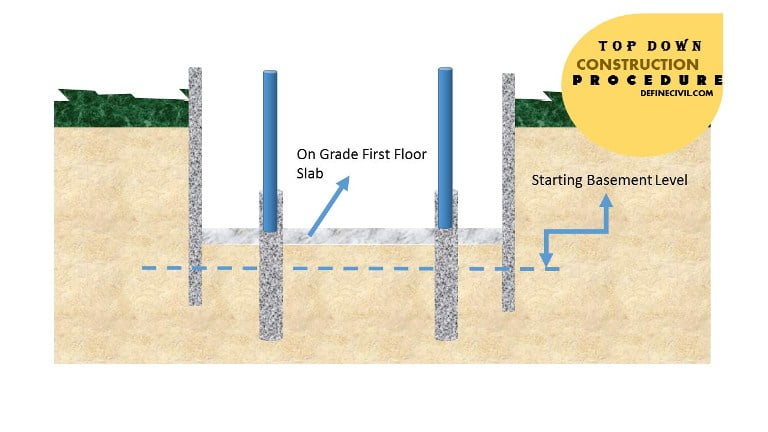

- After that the space contained within diaphragm walls are excavated to the level of ground floor slab. The ground floor slab is than concreted with steel reinforcement embedded in the diaphragm walls. Usually at the level of floor slab, rebars with end couplers are left while casting diaphragm wall which are later on connected with the reinforcement of ground floor slab.

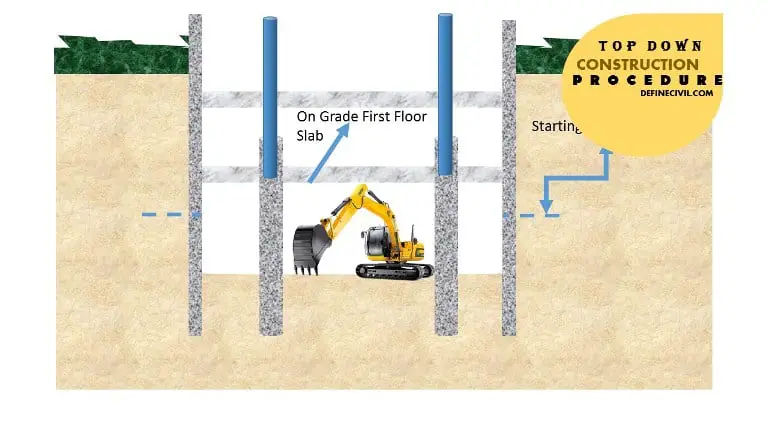

- The slabs have access voids at suitable distances through which the excavation is continued downwards for the second level of excavation or the first basement floor level.

- After achieving the depth of one level of basement, the steel stanchion columns are reinforced by reinforcing bars and are made as permanent columns for the basement floor and similarly the diaphragm walls are also reinforced with increased thickness to become permanent part of the structure.

- The process is repeated floor by floor of basement to achieve the required number of basement floors. The access points in the slabs left for excavation purposes are later on filled in with reinforced concrete slabs too match that of the floor slab.

The above procedure is actually more sort of a generic one and it is for sure going to be different for a particular project.

Top Down Construction Advantages

Although this technique of construction requires some extra planning along with some design modifications as compared with the traditional style of construction. But after reading to the top down construction vs down top or down up construction it is easy to conclude that it has many benefits.

- The substructure and superstructure can be constructed in analogous approach.

- There is minimum or no ground disturbance at all to the surrounding buildings.

- You don’t have to worry about the underground water.

- The project can be completed earlier.

- No heavy duty scaffolding and excavation supports are required.

- Because of confined excavation the problem of dust is completely avoided.

Here is a case study of one of the project carried out of deep metro station.

[su_slider source=”media: 295,296,297,298,299,300″ limit=”8″ link=”image” target=”blank” speed=”200″]

Sample Projects as application of Top Down Construction Excavation

Usually the top down construction method is used in urban infrastructure projects like of underground car parking, underpasses or even subway stations and alongside sky-scrapers with deep basement levels. Anyhow I have collected a list of some very interesting project involving top down construction excavation:-

Post Office Square Garage in Boston (7-levels deep)

It is a square situated in Boston, Massachusetts. The building stands on a parking garage that goes deep 80 feet into the ground marking as deepest excavated point of the city. The underground garage was constructed using the top down construction methodology done by Franklin, Milk, Pearl and Congress streets. The excavation for the basement was completed in 1990 and the reason for opting top down construction was that there were tall buildings up to 40 floors.

Beth Israel Hospital in longwood area of Boston Massachusetts USA with 22 m deep excavation.

Deep Metro Station at West Shanghai Railway Station.