Soundness test of cement by Le-Chatelier apparatus is very easy but very important test along with many other quality tests on cement.

Before going to the exact details, procedure and calculations of soundness test of cement by Le-Chatelier apparatus, let’s first discuss about the overview of soundness.

A sound cement doesn’t undergo volumetric changes i.e. expansion or contraction during its conversion from plastic paste state to a hardened state.

As an engineer what behavior do you expect from a structure that swells when gets hardened?

Have ever you heard or witnessed water supply lines being blown out in winters due to icing of waters therein? So if you answer to above questions you would know how destructive the unsoundness is.

The word soundness has a meaning of reliability and trustworthiness so in a rigid construction material like concrete; the soundness is an imperative property.

[su_box]The apparatus was named after a French chemist who invented this principle named Henry Louis Le Chatelier who was an expert chemist.[/su_box]

Significance of Soundness Test of Cement

In terms of Portland cement, according to Portland Cement Association (PCA), “soundness” is the ability of the cement to withstand any change in volume after setting and hardening.

In simple words sound cement is the one that does not changes its volume much after it gets hardened. The excess lime or magnesia content in cement that produces free CaO and MgO are said to be responsible for the unsoundness.

Beside this some other factors that can cause unsoundness in cement is improper or inadequate burning and grinding in kiln, poor original composition, excess of sulfate or magnesia and a very fine size.

Beside other ingredients of cement like Magnesia, Iron Oxide, Silica, Alumina and alkaline; lime is the main ingredient constituting about 70% of cement. If lesser lime is used in the cement than it would set quicker but excess of it would cause unsoundness.

If the soundness of the cement is not tested and there is an appreciable change in volume of mortar after setting that it will cause cracks in the concrete body and had severe impact on the structure due to which the durability of structure would be uncertain.

Overview of the Test

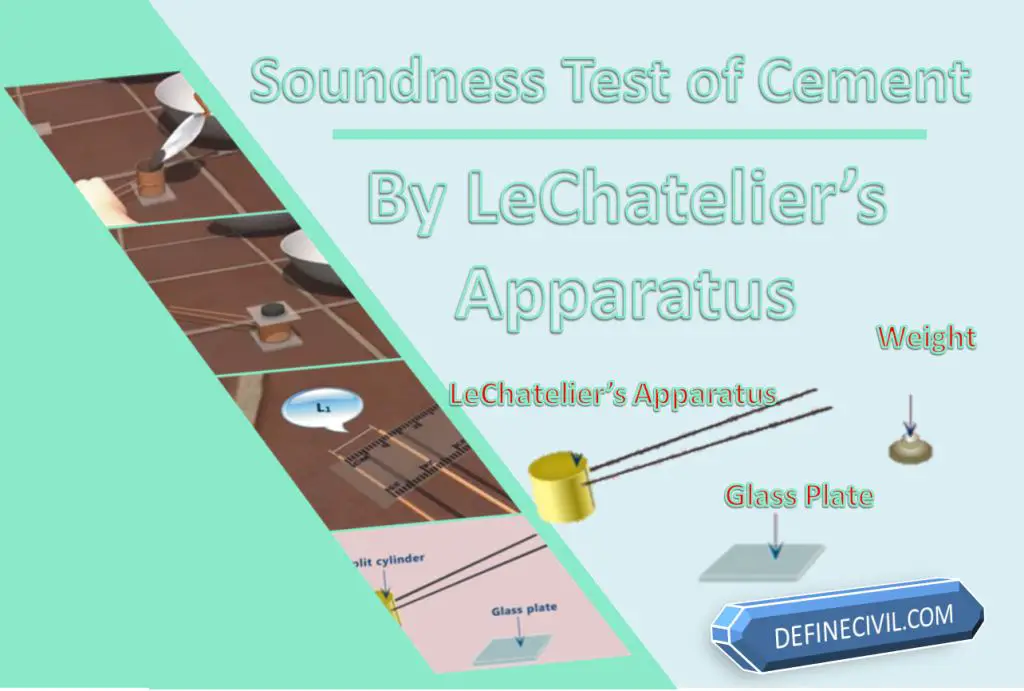

The apparatus used for the testing of soundness of cement is known as Le-Chatelier apparatus. The apparatus should be in accordance with the IS:5514 which is standardized by Bureau of Indian Standards (BIS) published in 1996.

The standard procedure that is followed in the laboratory is standardized as per IS: 4031 (part-3) – 1988. Although there are two methods for calculating the soundness of cement :-

- Autoclave Method

- Le-Chatelier Method

But in this post I would only talk about the Le-Chatelier Method as it is the most common method and is widely used in the field and projects.

Apparatus

Le Chatelier Apparatus which is the major tool that would be used for this test is composed of a split metal cylinder having clear internal dia of 30 mm (1.2 in) and same height while the thickness of wall is 0.5 mm. \

On both the cylinders of Le Chatelier apparatus for determination of soundness of cement; two indicating needles called indicator arms are fixed with length of 165 mm (6.5 in) which are actually used to determine the change in volume.

Beside Le Chatelier apparatus the equipment required is as follows:-

- Le-chatelier Mould

- Glass Plates

- Weigh Balance

- Water Bath

- Mould Oil

- Measuring Scale

- Shovel for Mixing of cement mortar

- Bowl for mixing of cement

Procedure

Before performing the soundness test of cement by LeChatelier’s Apparatus the standard consistency of the cement paste must be determined by using standard method test. After finding the amount of water that is required for the preparation of the cement past of standard consistency, the test is commenced.

- First of all the mould of the Le-Chatelier’s apparatus and the glass plates are applied slightly with some oil so that the cement past could not get stuck with them.

- A sample of 200 grams of cement is taken in a bowl properly weighed with the help of physical balance.

- The weighed sample can be placed in a mixing tray along with a pit made within it for addition of water.

- After that 0.78 times the weight of water required for standard consistency is taken in a jar.

- The water is then added to it and the cement paste is uniformly mixed with the help of showels.

- After that the oiled Le-Chatelier’s mould is placed on an oiled glass sheet and the cement paste is added in it.

- After filling the mould the other small glass sheet is placed on top of it and some weight is placed so that the assembly may not get disturbed.

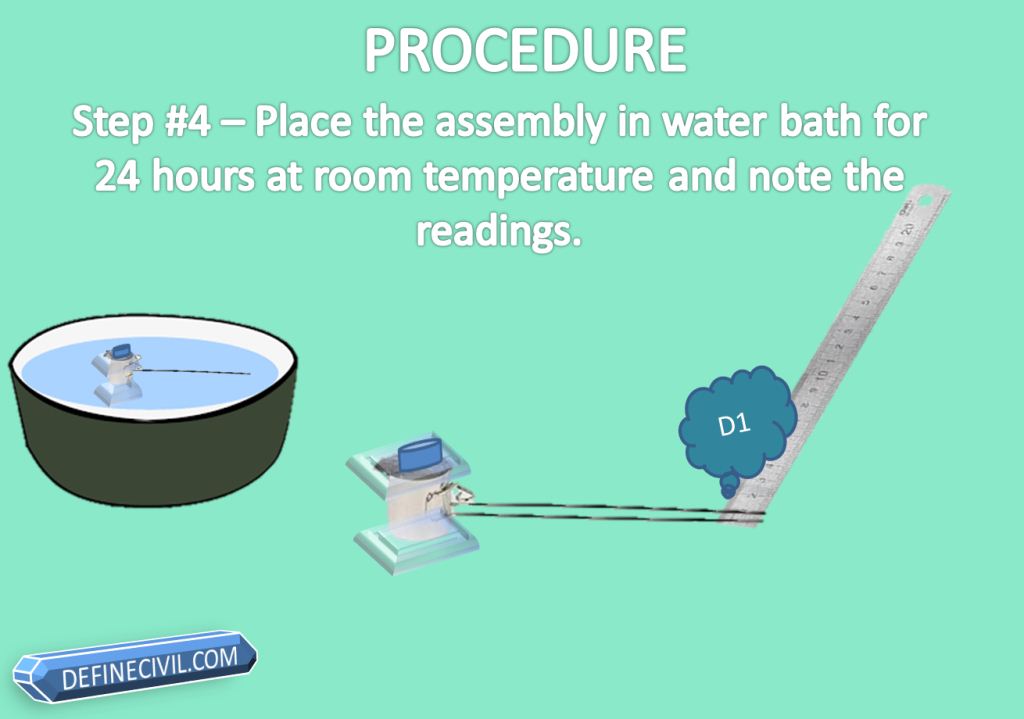

- The assembly is then placed in a water bath at room temperature i.e. 27 ± 20 C for a period of 24 hours after which it is removed and the distance between indicator needles is noted with the help of measuring scale up to 0.5 mm accuracy. Note this reading as D1.

- After that the assembly is then placed in water bath and is heated up to boiling point for 25 to 30 minutes and is then kept there for 3 hours after which it is allowed to cool up to room temperature.

- Again the reading of distance between indicator needles is noted as D2.

Must Read: Properties of Hardened Concrete

Calculation

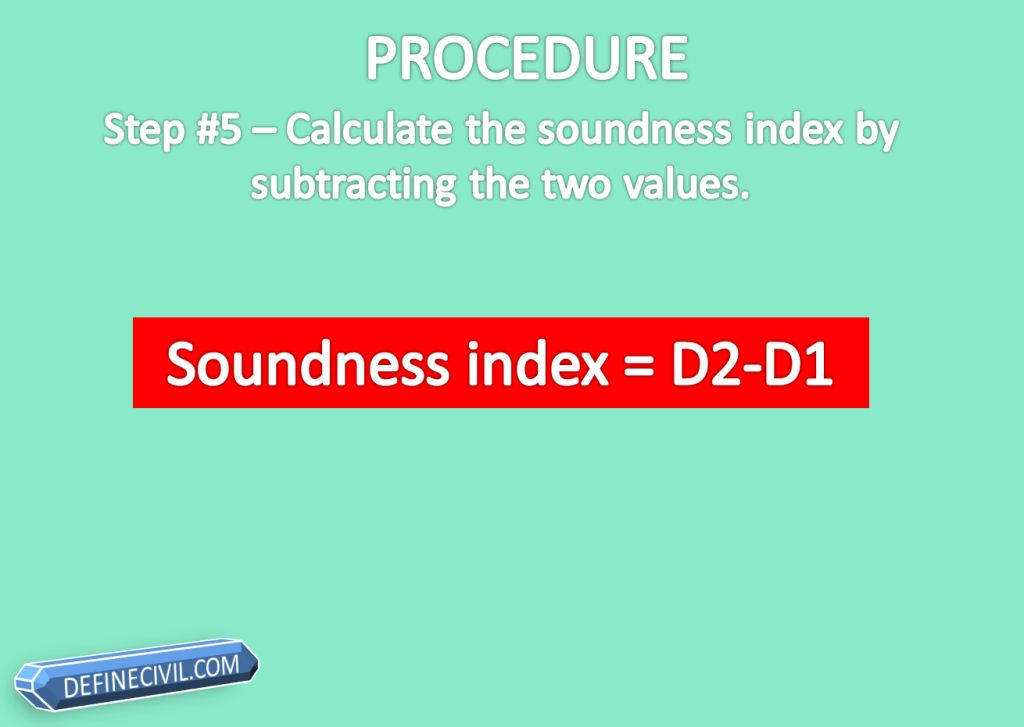

The distances noted in the procedures for the Le-Chatellier’s apparatus is just subtracted to get the soundness index of the cement.

So;

Soundness or Expansion of cement = D1 – D2

D1 = Measurement or distance between indicating needles after 24 hours of immersion in water at room temperature

D2 = Measurement or distance between indicating needles after 3 hours of immersion in a water at boiling temperature.

Precautions

- The oil must be uniformly applied on the mould and the glass plate to avoid free movement of the split cylinders in case of expansion in cement.

- The readings must be taken carefully and the indicator needles must be free from any pressure and should not be twisted or damaged.

- The apparatus must be cleaned after performing the test to avoid any permanent damage to it.

- The weight to be placed on the assembly must be of reasonable magnitude that could allow the full submergence in water without damaging the assembly.

- During filling of the mould not compaction or stroking is needed it should not be disturbed much.

Important Questions & FAQs

- Why we should take 0.78 times the weight of water for normal consistency of cement.

As we know that the lime present in cement combines with water while the remaining free lime and magnesia have increased volume causing unsoundness in cement. So we want to test the cement for the worst case so that’s why 78% water is taken instead of 100 percent.

- If the soundness index is not within permissible limit what should I do?

Well, if the value of the expansion is more than allowed; you must not use that cement in your project as that would cause excessive destructive expansion which will compromise the structural integrity.

- We have got cracks in concrete even the soundness of cement is below the maximum value. What’s the reason?

There are actually many reasons for cracks, as I have explained that expansion is one of many reasons. You must investigate your cracked structure and monitor the cracks before arriving at a conclusion. The cracks could be because of

- The improper curing of concrete.

- Bleeding and removal of cement grout from the concrete matrix.

- To presence of air voids and poor compaction of concrete.

- When to use autoclave expansion test and when to use Le-Chatelier’s apparatus?

According to ASTM C151 / C151-8 is the standard for the autoclave expansion test of the hydraulic cement.

Watch this amazing video I have made explaining every thing about this test.

[su_youtube url=”https://youtu.be/jwDjT2lWKzI” width=”460″]