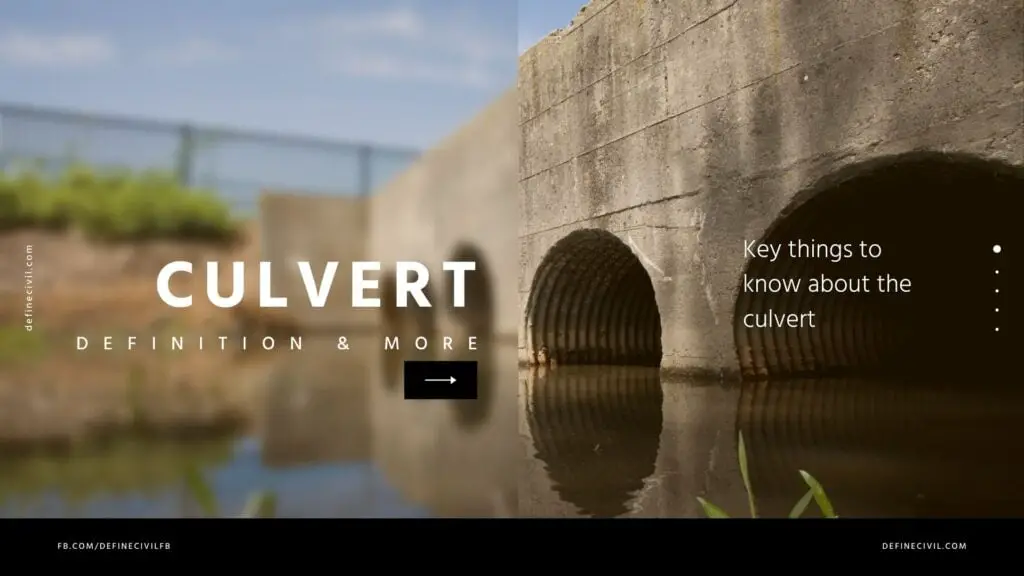

A culvert is basically a structure that allows water to pass through a roadway, train, trail or other structure from one side to another. In most cases, it is embedded in soil in order to be protected from the elements. The culverts may be constructed either with a concrete pipe, steel tubing or other flexible material. In many cases, this structure is necessary for the safe passage of water along a trail or stream.

While it may seem somewhat obvious on the one hand, understanding the definition and benefits of a culvert and their installation is imperative for those who are interested in installing such structures on their property. So, in this brief article, several different types of culverts have been discussed.

Definition

A typical culvert is like a trench or box shaped construct designed to transport large amounts of water away from the property. It can be a permanent or a temporary drainage structure primarily built to carry railway or road line over pre-existing channels or rivers.

Now what if you won’t provide a culvert? Well, in that case the water can keep piling up at one edge of the road until it can rise to the top of the roadway. Once it’s there, the road structure would be exposed to erosion and further damage.

So, here’re two basic functions that a culvert perform

- It allows the safe passage of water obstructing a highway, roadway, or railway trail.

- It protects the roadway from erosion and damage from the impounding water.

Parts of a Culvert

Essentially, any pipe or other flexible material that you use for culverts has two ends – one straight, and the other sloped. The slope or inclination will determine the speed at which water would travel through the culvert. Anyhow, here’re some parts of a typical box culvert:

- Pavement

- parapet

- Headwall

- Dingwall

- Crown

- Apron

- Road embankment

- Culvert inlet

- Culvert pipe

- Culvert outlet

- Culvert foundation

Materials for Culverts

As a result, culverts are generally constructed with concrete. This construction method provides several advantages over alternative options such as an embankment pipe system, steel tube embankments, and buried pipe systems.

Concrete

First, concrete is inherently more resistant to damages caused by environmental factors such as rainfall, snow, and ice. It is also capable of resisting pressures that could cause damage to the pipe walls. Lastly, concrete is a very economical option when compared to other materials such as steel and asphalt.

The installation process for what is commonly referred to as “box culverts” typically begins with a steel trench. This is then followed by the application of what is known as “shore line concrete”. This is a highly flexible slab that is implanted directly onto the pavement of the adjacent structure. Once this is dry, the concrete is then secured and frames are installed.

In the construction of what is commonly referred to as “box culverts”, multiple numbers of steel reinforcement are placed on the roadway in order to create a series of strong points that are aligned with the main body of the culvert. Multiple numbers of steel ties are then placed on the ground beneath the pavement, while the roadway is constructed. In most cases, multiple numbers of steel ties are placed on each corner of the box culverts.

Also read: Difference between bridge and culvert.

HDPE Pipe

An alternative to the concrete box culverts of the past are what is commonly referred to as “HDPE” pipes. While there are not traditionally known as “HDPE” pipes, they are in fact designated as such by the California Department of Transportation (CAD). These specialized roadway structures are composed of two different materials – flexible polyethylene (fiberglass) and flat steel. The flexible polyethylene is typically used in commercial applications, whereas the flat steel is typically used on residential streets.

Although it takes a bit more time and effort to construct a traditional or culverts, there are benefits to using high density polyethylene as well. One of the benefits of using HDPE in place of traditional pipes is that the material can be manufactured to specific shapes and sizes, and can then be shipped to almost any location in less time.

In addition, many HDPE pipes come with a life expectancy of twenty-five years or more. Because of this, the installation of a culvert constructed with HDPE can be a cost-effective long-term solution for any landscape project.

Also Read: Zero Force Member In Trusse – Definiton – Identification Examples

PVC

With respect to the depth of either the driveway or the sidewalk of the area in which a culvert is located, different types of pipe culverts may be used. For example, in some cases, a two-foot wide, one-inch thick PVC pipe is used to support the structure. The actual depth of the soil at the bottom of the driveway may vary, and the application of PVC pipe may vary as well.

Types of Culverts

Arch Culverts

– Arch C culverts: The arch culvert refers to precast or raised arch concrete forms generally used as a component of the main channel of the river for large spans and embankments. The arch culverts may be constructed directly onto the banks or may be constructed in mounds, which provide a firm and safe footing. They are most often used for low-clearance structures such as railway viaducts. The main appeal of concrete arch culverts is their strength and capacity to withstand torrential downpours. Although the construction cost may be high, at least they can be transported by crane.

Box Culverts

A box culvert generally consists of a rectangular or circular shaped box formed into a solid shell. The length of an arch culvert depends on its width and thickness. To manufacture the solid shell, various materials like crushed stone, corrugated steel, vinyl, wood or insulated concrete are used. The concrete mix design of an arch culvert facilitates the expansion of the concrete leading to better flexibility. However, they are prone to damage by water and also have a lower capacity than other types of culverts.

Top heave Box Culvert

The topheave box culvert comes with two parallel layers made from steel to support the bridge. The steel layer is generally considered as the strongest layer as compared to the other two. The concrete that forms the bottom surface is known as the overhangs. They are usually wider than the rest of the concrete and hence they give strength to the structure. They are also known for their resistance to extreme weather conditions.

Solid Concrete Box Culvert

The solid concrete box culverts have a deep slot in the center that is wider than the length of the shell. The slot has a very deep curvature so that it can accommodate a vehicle lying in the same depth. The depth inside the slot may vary depending upon the use of the vehicle. They are considered to be the cheapest among all types of culverts.

Arch Concrete Bridge

This type of culvert is generally made up of rounded or rectangular shape. It is used for both motor vehicles and bicycle. The concrete used for making these types of culverts can be expanded easily. However, it is not easy to maintain them because they tend to break or crack due to heavy rains and strong winds. On the contrary, arch culverts do not experience much change in their width.

Pipe Culvert

It is the simplest of all types of culverts, discussed prior. You can use one pipe or more side by side to adjust the opening requirements based on the flow requirements. Pipes are available in different types of materials like Cast iron, PVC, Steel, or RCC. Pipe culverts are very common due to the ease of installation. However, pipe culverts are only feasible for small type of drainage works or for low flows.

Advantages and Disadvantages of Culverts

All the types of culvert have their own advantages and disadvantages. In case of concrete box culverts, the biggest advantage is that they are cheap. In case of an arch culvert, their greatest advantage is that they can support a greater weighty load. As a result of this wide shape, they provide adequate support to the heavier vehicles. However, they are quite expensive.

Culverts are pretty useful in preventing erosion of the road embankment. In the absence of a culvert, the water can seep inside the subgrade and sub-base of the roadway causing deterioration and foundation failure of the road.

With such, it does not allow water to impound on one side of the road embankment. So, it prevents flooding and avoid overflow. Designers use culverts to divert water for farming purpose.

But still there’re some pitfalls and drawbacks of using a culvert.

First of all, it is not economical in some cases where the discharge of water is too much or the span is more. The design of culvert is bit more complex and installation is also bit difficult.