Air permeability test or Blaine’s air permeability method is one of the most accurate methods of finding the fineness of the cement. In this method, we determine fineness of the cement with the help of an apparatus patented by LEA and NURSE, it is done by the NURSE and BLAINE’S method as, apparatus consists of the permeability test cell and plunger along with sets of the discs (perforated and non-perforated).

Background of the test

Cement is filled in the cell and air pressure is applied by the apparatus. The air pressure is calculated by measuring the difference between pressure and manometer.

As fineness of the cement can be checked by the following tests:

- Sieve methods

- Air permeability methods – Nurse and Blaine’s method

It is the most accurate method of testing the fineness of the cement particle and we’re going to discuss this method in today’s post.

- Sedimentation method – Wanger turbid meter method

I’ve already explained fineness of cement by sieving in another post don’t forget to read that article for in-depth knowledge of fineness of cement.

Also Read: Fineness of Cement Test by Sieving

Standard

The Blain’s air permeability test method is standard by American Society for Testing Materials vide standard ASTM C 204-07. For the Asian region the test is standardized as per IS 4031 Part 2.

Objectives of the test

There are following objectives of the air permeability test on the cement:

- To determine the rate of hydration of the cement

- To determine the evolution of the heat

- To determine the cement water reaction

- To determine the strength of the cement

- To determine the fineness of the cement

What is fineness of Cement?

Here’s how we can define the fineness of cement.

The specific area of the cement particles measured and expressed in units of area is termed as fineness of cement. It describe the cement particle are coarser or finer.

Fineness of cement is defined as the property of cement that indicates particle size of cement and specific surface area of the cement. This property indirectly effects heat of hydration. Fineness must be in range between 5% to 10% of residue by weight.

What is degree of fineness of cement?

It is the measuring of the average size of the particle or grains in the cement.

As the cement particle are much finer, the higher will be the degree of the fineness of the cement.

Fineness of cement and Rate of hydration reaction Explained

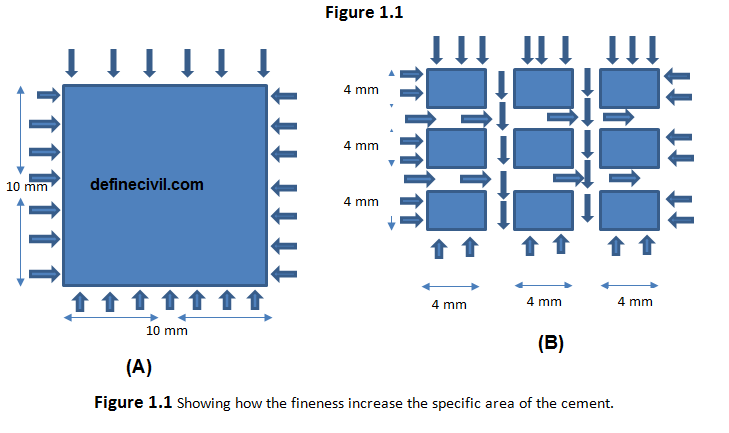

Fineness increases the specific area of the cement particle as shown in the following figure:

Area of the front face of the cube = 10 x 10

Area of the front face of the cube = 100 mm2

Area of one smaller square fine particles: 4 x 4 = 16 mm2

Total area of the smaller cube = 9 x 16

Total area of the smaller cube = 144 mm2

It is seen that fineness of the cement increase the surface area and if the surface area of the cement is increased then the water will find more space to react with the cement and as a result hydration of the cement is enhanced and as the hydration will be more, the ultimate strength of the cement will be more.

Therefore, we can analyze the surface area increases, as the cement particle gets finer.

Surface area = 144 mm2 > 100 mm2

Impact of fineness of cement on different properties

Here’s how fineness of cement impact on different properties of cement:

- It increase the workability as the water requirement increases due to fineness.

- It increases the rate of the hydration and much strength gains in initial time.

- Bleeding can be reduced by the increment of fineness in cement.

- It increase the final setting time of the cement

- It also increases the dry shrinkage and at some extent of fineness, the hydration as much exceeds that the water cement (w/c) ratio decreases and strength decreases after that.

- It is easily susceptible to shrinkage and cracking

- Finer cement reacts more strongly in alkali reactive aggregate

Apparatus:

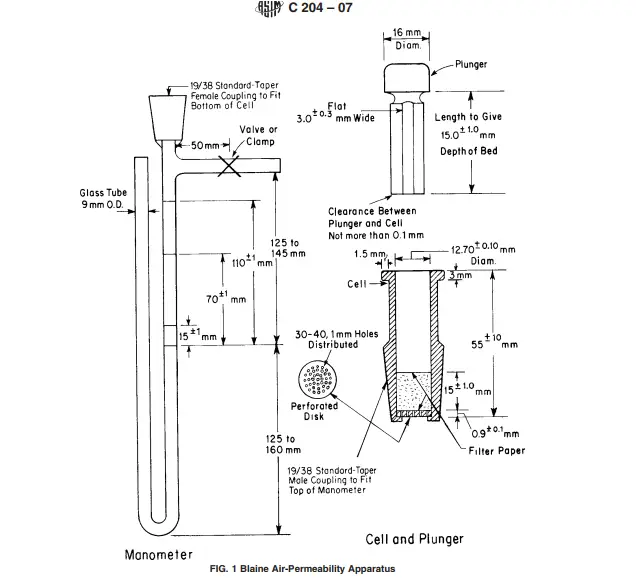

Following apparatus used for Fineness Test of Cement by Blaine Air Permeability Method:

- Blaine Air Permeability Apparatus

It consists essentially of a means of drawing a definite quantity of air through a prepared bed of cement of definite porosity.

The number and size of the pores in a prepared bed of definite porosity is a function of the size of the particles and determines the rate of airflow through the bed.

- Permeability cell and Stopwatch

- Manometer

The U-tube manometer shall be constructed according to the ASTM C204–07

- Manometer Liquid

Dibutyl Phthalate (Dibutyl1, 2-Benzene-Dicarboxylate)

There must be at least three points (A, B and C) marked on the manometer for the checking the air entrainment of the cement.

- Filter Paper

- Plunger

- Weighing balance

- Pycnometer or other convenient

- Light oil or Light grease

- Mercury with glass plate

- Circular discs (perforated and non-perforated) of filter pape

- Cement sample of known specific surface area (S).

The figure of whole apparatus with their specifications is given below taken by the standard ASTM C204–07

PROCEDURE:

- Laboratory test conditions can be set as the temperature T = 27 °C and relative humidity can be set as 65

- Firstly, place the plain disc into the cell at the bottom and level it by a rod

- Place the filter paper of 7 microns diameter and level it by the rod on plain disc

- Place the cell into the beaker or water bath, fill the cell by the mercury and level it by glass plate.

- Weight the mercury which is filled into the cell and it is the first reading WA

- Put the perforated disc into the cell and level it by the rod and also put the filter paper and level it too on the edges

- Take 2.8 grams of the cement whose surface area is known by standard as SO = 3100 cm²/g. Add this standard weighed cement into the cell and put again filter paper on it and press it by the help of lubricated plunger as no air bubble remains in the cement.

- Refill the mercury and press it by the glass plate and weight it again by the balance which is 2nd reading WB

- Calculate the bulk volume occupied by the cement to the nearest 0.005 cm3 as follows:

V = (WA – WB) / D

where;

V = bulk volume of cement cm3

WA = grams of mercury required to fill the cell

WB = grams of mercury required to fill the cell over the cement filled.

D = density of mercury at the temperature of test Mg/m3.

Make at least two attempts for the bulk volume.

- Find the mass of the cement:

M = W = ρV(1 – ϵ)

where:

W = grams of sample required,

ρ = density of test sample (for Portland cement a value of 3.15 Mg/m3 or 3.15 g/cm3 shall be used)

V = bulk volume of bed of cement in cm3

ϵ = desired porosity of bed of cement (0.500 + / – 0.005)

- Attach the cell on top of the U-tube manometer. Evacuate the air in the manometer through the side tube using the aspirator bulb until the manometer liquid reaches point A

- Now remove the plunger from the cell and the cock at the other end and note the time on the stopwatch until the manometer’s liquid reach at the point from A to B and then C.

- This is the time for the standard cement and repeat the procedure for sample of the cement and record the time for the observing sample of cement whose specific area to be known in the experiment.

- As the time for the standard sample of cement is known TO and now the time of the observing sample is to be known TS is also recorded.

- Using following relation for finding the specific area of the observing sample:

S = SS × square root (TS/To)

Where;

SS = 3100 cm²/g

TO = time for sample to be observed

TS = time for the standard sample

RESULTS AND DISCUSSIONS:

- As the true mean size of the cement can’t be determined by the help of sieve test method as the cement attaches to the sieves being finer in size. That is why the air permeability test on cement is more authentic and is carried on as the specific area of cement is known and compared with the standard samples.

- A well pulverized cement by the machines is more productive and the fineness will be more and this type of cement gives the higher rate hydration and higher initial and final strengths. As fine particles of the cement provides much paths to the water to react with than the other less fine particles of cement.

- Different researches shows that a limited fineness of the cement particle enhance the strength as if cement is made more fine then it starts decreasing the strengths.