Masons apply different type of finishing between the layers of brickwork that is known as pointing. The mortar used to lay the stone or brick is mostly of lime or cement, depending on the age of the building. Homeowners prefer brickwork pointing over plastering or other finishing reserving the natural texture and color of the bricks. For such, rather than plastering the entire brick surface, masons apply a specific mortar over the exposed joints.

Let’s explore brickwork pointing in details along with different styles of pointing in brickwork.

Pointing in Construction

Raking the joints to a depth of 10 mm to 20 mm and filling them with richer mortar mixtures are some of the approaches.

Types of pointing

Lime mortar pointing has a 1: 2 ratio, while cement mortar pointing has a 1: 3 ratio. Because stones have beautiful colors and an excellent resistance to water penetration, pointing is ideal for stone construction. But homeowners also use this approach in brick work. By repairing the weaker portions of the brickwork, pointing improves the aesthetic appearance of the masonry (i.e. joints).

Older constructions are irreversibly damaged by incorrect pointing. It’s vital to understand the function of mortar joints in the home’s structure. The mortar on the wall acts as a layer of foundation and can range in size from delicate stonework joints to larger rubble masonry joints.

To efficiently reduce the size of the joints, little bricks and ‘cut’ bits of bricks are used. Masons call these cut bricks as brick bats.

See Also: Standard Brick – Brick Dimensions that you MUST Know

Role of mortar in pointing

So, how would you select a type of mortar for pointing?

Well, the mortar must perform the following functions in addition to serving as a bed or foundation:

- It must keep water out of the joints while also allowing the wall to breathe and drain, with porosity being a key consideration when selecting a mortar.

- Internal settling and heat reactions cause the structure to move/settle, hence it must be flexible. (see heat of hydration of bogues compounds). The usage of modern expansion and contraction joints was not used in many older, huge structures.

- The mortar should always be weaker than the stones around it, and it should be regarded as both a sacrificial part of the wall and a maintenance item that needs to be replaced every century or two.

- The various issues of water infiltration caused by other building failures such as gutters, roofs, and lead cannot be evaluated separately, and eliminating any walls will not fix water infiltration issues caused by these failures.

- The walls need oxygen to breathe, and if the signal prevents them from doing so, they will quickly deteriorate. A wall’s lungs are the mortar joints, which enable water to readily enter and depart the structure. If water tries to escape through stone or brick, it will eventually ruin it. If the mortar joints are blocked, the wall will be damaged.

- The mortar must be softer than the wall’s construction material. The indication should match the wall’s building material and act as a secondary visual help.

See Also: Properties of Bricks -Compressive Strength -Hardness – Efflorescence

Types Of Mortars used for pointing work

There are different types of mortars used for pointing works:

- Lime Mortar

Lime mortar is made by combining fat lime, fine sand, and water in the proper proportions. For pointing work, lime mortar in the ratios of 1:2 or 1:3 is commonly employed.

It is primarily employed in the conventional pointing of new buildings and structures, as well as the pointing of historic ones.

- Cement Mortar

A proper mixture of cement, sand, and water is mixed to make cement mortar. In most cases, pointing work is done with a 1:3 cement mortar. To avoid the mortar setting too quickly, use it within 30 minutes of preparing it. It is employed in the pointing of both new and existing structures.

- Surkhi Mortar

A appropriate quantity of the compound lime, water and a substance called surkhi, is used in the making of surkhi mortar. In most cases, pointing work is done with surkhi mortar in a 1:2 ratio.It’s typically employed in the pointing of historic constructions and buildings.

See Also: Brick Bonds -English Bond -Flemish Bond – Header Brick Bonds

Advantages of Brick Pointing

If you’re still wondering if pointing is necessary or if it is a good technique, here’re some pros of brick pointing:

- Pointing keeps the wall structure safe from adverse weather effects.

- It improves the structural strength of the building by providing a foundation for the wall.

- It reduces the need of repair or rehabilitation work in future.

- There’s no need to use plasters or costly weather resistant paints on wall.

- It enhances the overall look of the wall structure.

See Also: Quantity of Bricks in a wall (STEP BY STEP Approach)

Methods of Pointing

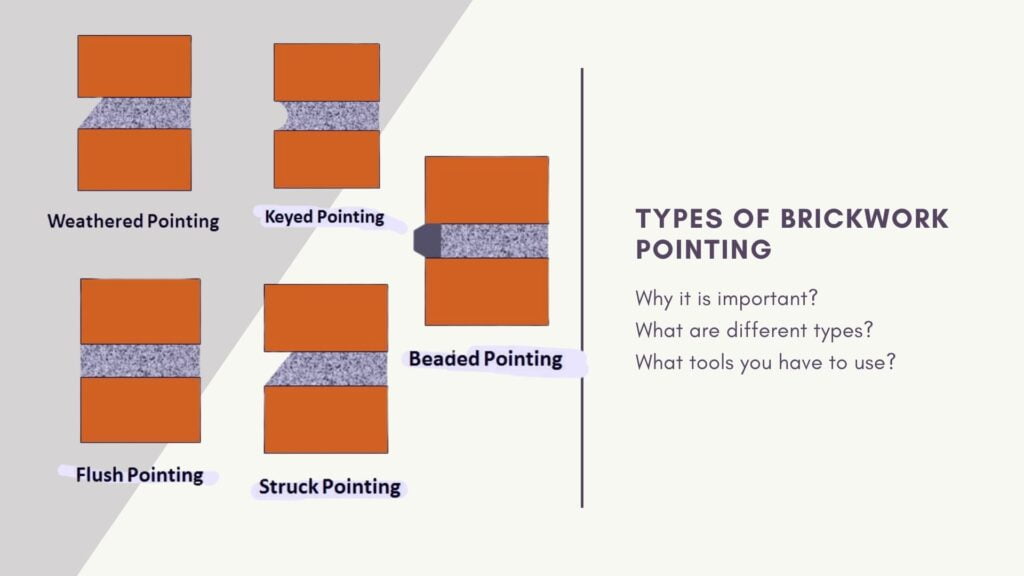

The various types of pointing are as follows:

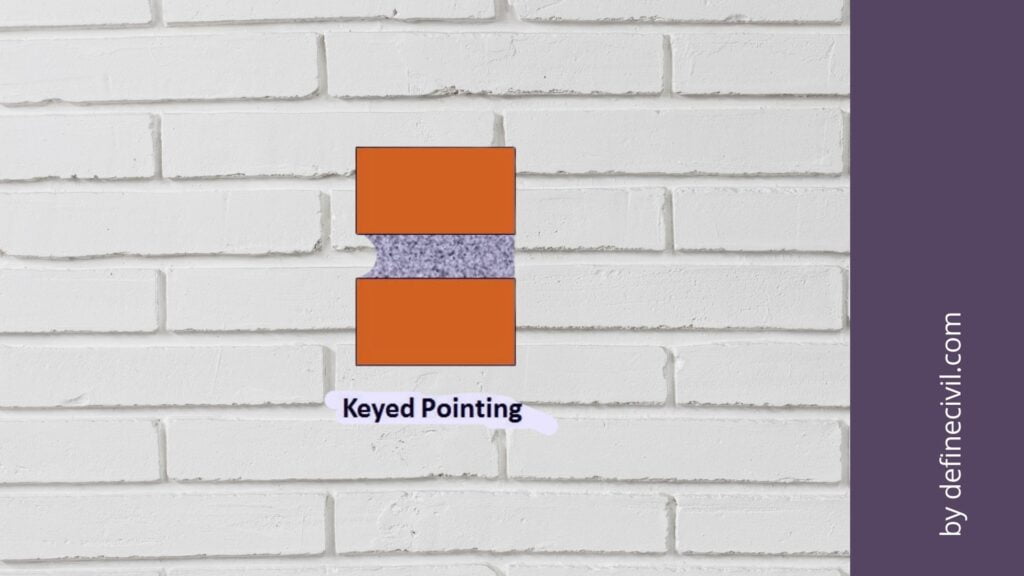

- Keyed Pointing

In this type of pointing, the mortar is completed with the wall’s face by pushing it on the joints. Before the mortar is set and while its still green, an engraving is created by passing the folded end of a thin steel bar (6 mm in diameter) straight down the centerline of the joints. Vertical joints are completed using the same manner.

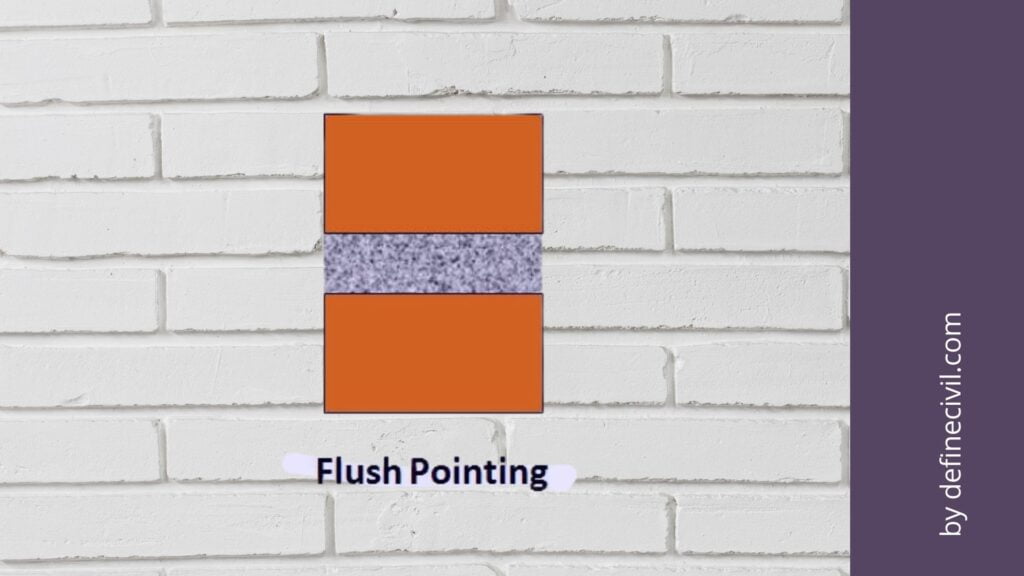

- Flush Pointing

In this method of pointing, the mortar is pushed and applied tight on the linked joints and ends flush with the edges of the masonry units. The edges are cleanly cut using a spatula with a straight edge. This method is no longer viable and aiming the flush, on the other hand, is more long-lasting since it prevents dust, water, and other impurities from entering the system. As a result, this method is widely employed.

- Cut Pointing

In this method of pointing, the mortar mix is forcefully forced into the joints first. While the mortar mix is still wet, the top sections of the horizontal joints are firmly pushed from 3 to 6 mm with the pointing tool. As a consequence, the joint is finished by tilting the joint from top to bottom.

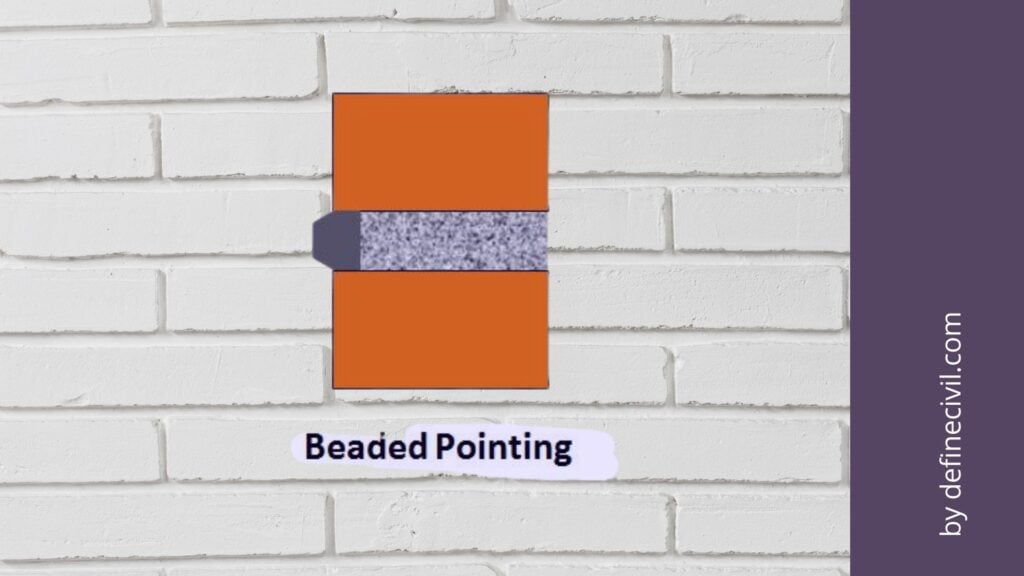

- Beaded Pointing

Steel or iron rod (metal) with concave edges are used to create it. It has a nice appearance, but it is more susceptible to injury than other varieties.

- Recessed Pointing

The mortar mix is applied 5 mm or more at the edges in this type. The face of the sharpener is held vertically during mortar placement with a suitable tool. It appears to be excellent in performance.

- V-Pointing (or V-groove pointing)

A V-groove is cut into the levelled finishing face to create this effect.

- Tuck Pointing

The mix of mortar is firstly pounded at the joint and then at the surface in this case. A channel is carved with a 5 mm width and 3 mm depth while the pressed mortar is still wet. The engraving is then filled with a mix of white cement that extends 3 mm beyond the joint’s face. It’s called a pointing bastard or half a bent point if the projection is produced in the mortar.

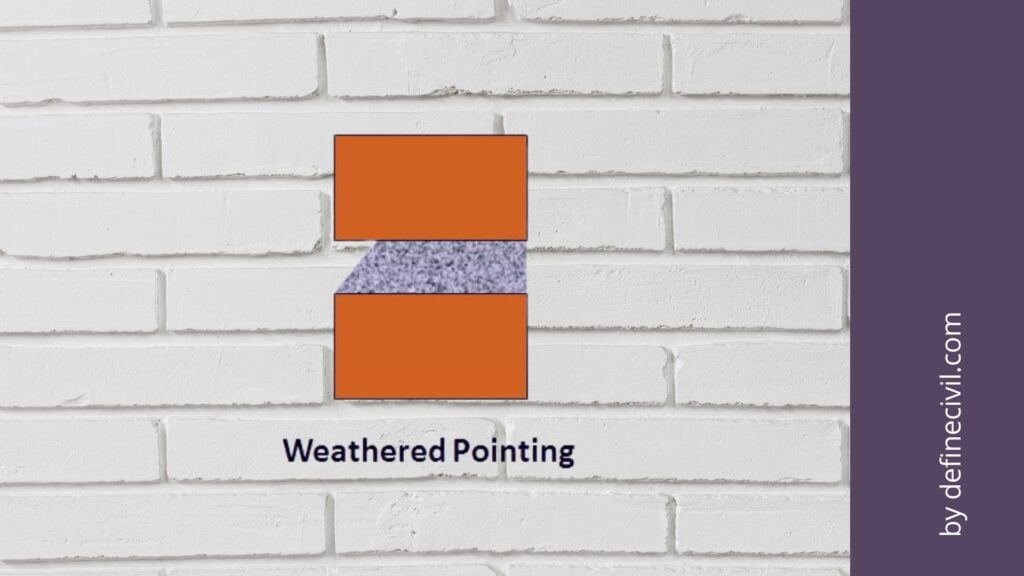

- Weathered joint pointing

As the name implies, this type of joint provides adequate weather resistance. It does, however, necessitate a significant amount of water.

- Struck Pointing Brickwork

This type of pointing is used where weather is mostly rainy and there’s a need to drain the rain splashes quickly from the brick joints. In struck pointing the mortar is filled and pressed inside the joint to match the face of the brickwork. After that, the top edge of the joint is pressed inside around 10mm in comparison to the bottom corner. This creates a slope from top to bottom for guiding the rain off the wall joints.

See Also: Different Shape Bricks (13 Shape Types I bet unknown to You)

Brick Pointing Styles

The most popular brick pointing styles are Flush Pointing · Tuckpointing · Beaded pointing · Weathered pointing · Keyed pointing · Recessed pointing · Struck pointing · V-Grooved pointing.

Brick Pointing Tools

You’ll need a brick trowel and pointing tool. Different types of pointing tools are available online. If you are going for a tuck pointing, make sure to buy pointing tool specific for tuck pointing. If you have concave mortar joints, you’ll need a masonry jointer that’s the width of your joints.

Alternative to repointing brickwork

Brick pointing is used to protect walls from the ingress of external dripping water or rains. So, the brick pointing is not always necessary if you have any external wall insulation. Moreover, if you are using a weather-tight rendering or plastering on your external wall, there’s no need of pointing for such walls.

See Also: Breast Wall – Definition – Advantages – Application – Design – Retaining Wall

FAQs

Is brick pointing necessary?

Brick pointing, if done correctly, not only help exclude the weather elements but also retard the deterioration of the wall. Moreover, a proper pointing can also enhance the visual appeal of the wall.

What is the best mix for brick pointing?

If you’re doing pointing for normal application, the best mix for brick pointing would comprise 1 part Portland cement, 1 part Lime and 5½ parts Sand. But be sure, this mortar is only ideal for use in an area subject to normal weather conditions.