You might have heard about concrete curing, a process of spraying water on freshly placed concrete. But probably have not heard about other methods of curing of concrete like using water-soaked hessian cloth or ponding. But do you know why concrete needs curing? Why curing is so important for the longevity and durability of concrete? So, in today’s post we’re going to discuss about curing, its different methods, and techniques, and why it is so important?

Curing can be thought of as the formation of a favorable physical environment for uninterrupted chemical reactions that take place during the early phase of concrete mixing.

Why water is added in the concrete?

A large amount of water is initially added to the cement ingredients while creating the mixture. The presence of water enables the mixing of various elements like cement, gravel, sand and other ingredients that mix and form the concrete paste. At this stage, some water may be lost through evaporation because of the chemical reaction called hydration. Now hydration reaction is an exothermic reaction that generates heat and results in loss of water. Thus, to compensate that water loss we need curing with methods like water-spreading systems or sprinklers.

While mixing the ingredients, water is applied on the wet ingredients using water spreaders or even a continuous flow machine. This process of applying water on the surface causes the ingredients to mix instantly.

What is concrete curing?

Concrete curing is the manual application, spraying, or ponding of water on the concrete surface to compensate the moisture loss results due to evaporation.

Curing of concrete depends on the initial curing period, which is defined as the time from when the water begins to evaporate until the resulting paste is formed. This is generally considered to be a critical point and measures are consequently in place to prevent excessive drying.

This can be done by regulating the temperature. Generally, the most important factor affecting the drying period is the difference in temperature between the fixed point and the area over which the curing is taking place. This temperature differential affects the rate of shrinkage.

Shrinkage can either be complete or partial. Complete shrinkage occurs when there is a total loss of water content. Partial shrinkage occurs when a larger amount of water evaporates, but not to the extent that the surrounding area is left wet. Under normal conditions, a good mixture of water and graphite or sodium silicate is mixed into the concrete mix to make it capable of resisting water evaporation and provide adequate hydration.

What is hydration reaction of cement?

Hydration is the chemical reaction between cement and water that results in the formation of various chemicals. These chemicals contribute to setting and hardening resulting in an exothermic reaction. So, in order for this process to go well, concrete must have sufficient moisture and temperature must be favorable.

Concrete curing duration and time

American Concrete Institute (ACI) recommends a minimum curing period corresponding to the attainment of 70% of the compressive strength of concrete. Experts have established the fact that 70% strength can be achieved in 7 days of curing in normal conditions. However, the strength can be achieved quicker when concrete cures at a higher temperature or when you use certain admixtures in the concrete mix.

What temperature is best for concrete curing?

You can expect to have a longer duration of concrete curing at lower temperatures. Anyhow, it is a well-established fact that 20 degree Celsius is the ideal curing temperature for concrete.

Importance

Concrete curing is an important process. It ensures that the concrete structure is strong and lasts for a long time. There are some disadvantages involved in the process. Although concrete is stronger and durable than other materials due to its chemical makeup, but it cannot withstand extreme weather conditions and is vulnerable to cracks.

Now normally a freshly mixed concrete has even more water than is required for hydration reaction of cement. But during this process of curing, there’s an excessive loss of water by evaporation. Such a loss can delay or prevent adequate hydration especially for structures that have more surface area exposed like in slabs or bridge decks.

Concrete also tends to expand and contract to a greater extent than other materials. That’s why you can see in general specifications of the project that Contractors have to use ice in concrete to lower its temperature during hot weather. Some other methods of avoiding hot temperature is covering aggregate stockpile with sheets or applying cold water on the transit mixer drums.

Thus, you need to ensure methods to retain moisture in the concrete until it has attained sufficient compressive strength. Curing directly influences the quality of your overall concrete structure. Here’re some benefits of proper concrete curing.

- higher durability of concrete

- enhanced strength

Methods of Concrete Curing

All different methods of concrete curing are meant to maintain adequate moisture in concrete within a proper temperature range. Concrete needs feasible temperature and water to undergo hydration without having excessive shrinkage and deterioration.

Well, there’re many factors that affect the rate at which water evaporates from freshly placed concrete. Some of these factors are :

- Temperature of the atmosphere

- Humidity

- Concrete temperature

- Wind Speed

With that in view, construction experts and civil engineers have established many techniques and methods to help concrete retain moisture at the early stages. These methods also help reduce the loss of water from the surface of the concrete. They help accelerate concrete strength gain by supplying heat and adding moisture from the outside. Selecting one of these methods or combination of methods depends on the availability of curing material, size and shape of concrete structure, production facility in place, aesthetic appearance, and economics.

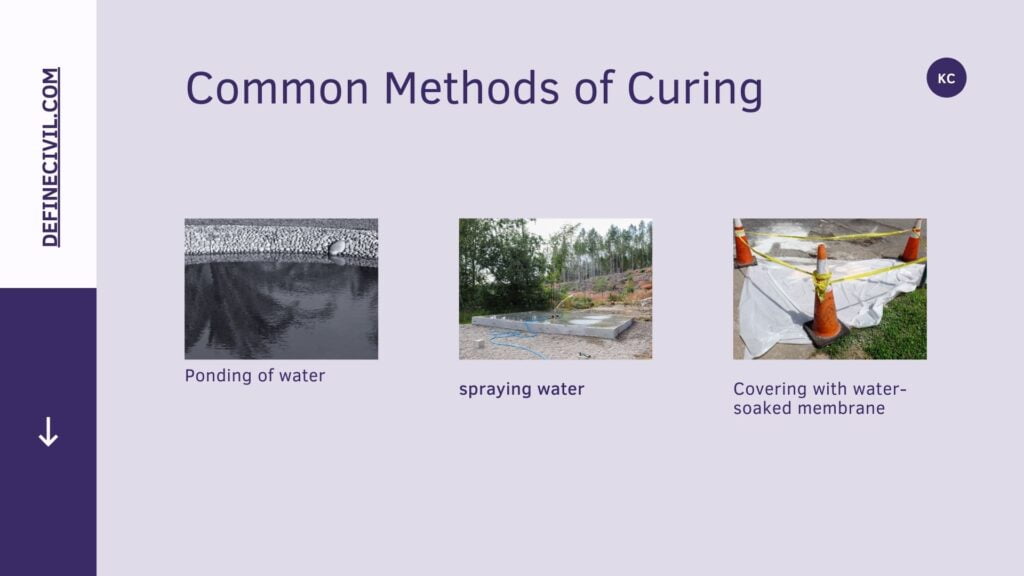

Here’re some of the common methods used for concrete curing:

Ponding

Ponding is typically used to cure flat concrete surfaces like pavement and floors. We use earth and sand placed around the perimeter of the concrete surface that can retain a pond of water. Ponding is ideal method for preventing loss of moisture from the concrete. Ponding is also effective for maintaining a uniform temperature throughout the concrete.

Spraying and fogging

Spraying and fogging methods are used when the ambient temperatures are well above freezing and humidity is low. Fog mist is applied through nozzles or sprayers to raise the relative humidity of the air over flatwork. This method helps slowing evaporation from the surface. Fogging helps minimize plastic shrinkage cracking.

Using water soaked fabrics

Another very common method of concrete curing is by application of water-soaked burlap or similar materials. These wet coverings saturated with water like burlap, cotton mats, rugs, or other moisture retaining fabrics can do wonders for curing of the concrete. Anyhow, you must use the fabric on the concrete to prevent surface damage. You need to make them wet constantly so that a film of water remains on the concrete surface throughout the curing period.

Using impervious paper and plastic sheets

In order to prevent moisture loss from concrete surface, we can apply impervious paper and plastic sheet layers on a thoroughly wet concrete surface. An example of such material is polyethylene film. It helps control moisture loss from freshly finished concrete surface.

Also Read: Concrete Retarders – Disadvantages – Types – Uses – Price

Using curing compounds

Membrane forming curing compounds is used to reduce evaporation of moisture from concrete. They can be clear or translucent. White pigmented compounds are generally recommended for hot and sunny weather conditions to reflect solar radiations.

Using steam

Live steam and high-pressure steam are two common methods of steam curing. The temperature for live steam is kept at about 140 degrees farenheit or less until the desired concrete strength is achieved.

Stages of concrete curing

American Concrete Institute (ACI) has defined three stages for concrete curing. These are:

- Initial concrete curing

- Intermediate

- Final Concrete curing

Concrete curing is carried out in these three phases. The length of the time for each stage depends on the concrete temperature and environmental conditions.

Initial Curing

During initial curing or settling, concrete sometimes bleed water. This water starts evaporating from the surface faster than it is rising out from the concrete. Due to high overall temperature, evaporation can happen faster than usual time. So, to avoid evaporation of the entire water, you need to do some initial curing and minimize moisture loss. If you won’t start the curing, it may lead to plastic shrinkage cracks in concrete. The initial concrete curing can also be done by fogging.

Intermediate Curing

After the finishing of concrete has been completed, intermediate curing is carried out. This phase of curing is sometimes necessary before the concrete has reached its final setting. Evaporation still happens at this stage but the concrete is not able to withstand direct application of water or the mechanical damage. Thus, it is recommended to use plastic sheet covers or use liquid forming membrane compounds.

Final Curing

Final curing is carried out after final finishing and after the concrete has reached its final setting. Final curing is carried out by application of wet covering like ponding or use of saturated burlap, spraying, water compounds etc.

Normally, the setting time of cement is not less than 6 to 8 hours. So, curing should start after minimum of 6 hours but not later than 24 hours.

Benefits of concrete curing

- Concrete curing is an important quality control and quality assurance aspect of all concrete structures. You need to ensure adequate control of moisture and favorable temperature of during concrete pouring.

- Curing in the right manner will prevent concrete from having excessive drying shrinkage or cracking.

- Curing will enhance the overall performance of your concrete structure.

Thus, it is essential to continuously monitor concrete curing conditions for minimum of 7 days.

If the water of concrete evaporates before it has attained maximum compressive strength, the concrete may not have adequate water than to achieve maximum compressive strength. You need to take care of the weather conditions during extreme situations.