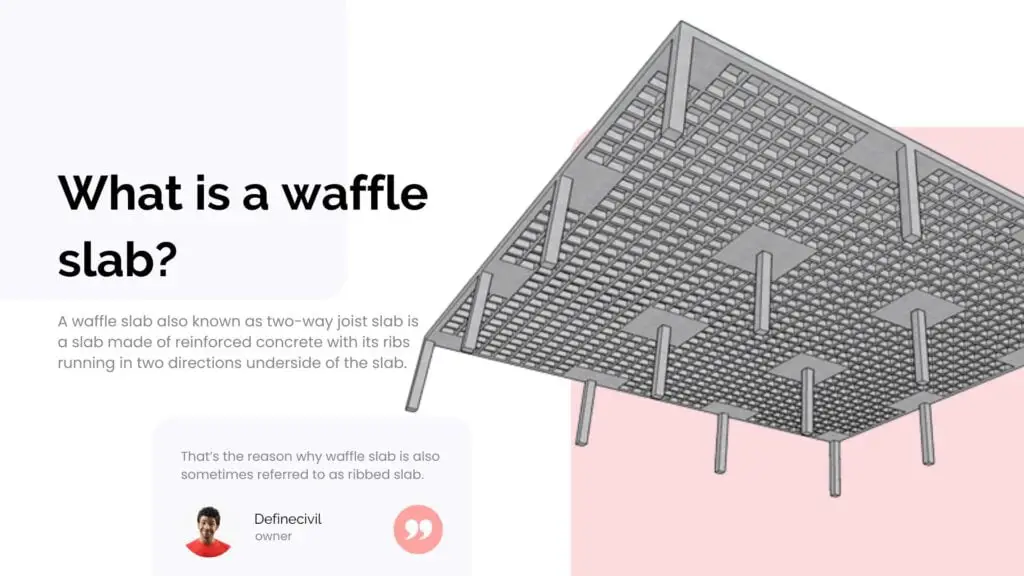

A waffle slab also known as two-way joist slab is a slab made of reinforced concrete with its ribs running in two directions underside of the slab. Ribs are wide band beams that run between columns spanning the orthogonal direction. That’s the reason why waffle slab is also sometimes referred to as ribbed slab.

The name waffle is given to this type of slab because of its grid pattern which is created by reinforcing ribs. Ribbed slab is flat on the top and grid like pattern is created on the bottom side of slab which also support the load. The shuttering of this slab is formed and then concrete is placed and when concrete is set the shuttering is removed.

This type of slabs when designed structural rigidity is consider more for longer spans with heavier loads. This structure because of its large rigidity is recommended for buildings like laboratories and manufacturing companies which require minimum vibration.

It can be designed for open spaces and railway stations as well. A Ribbed slab is composed by intricate formwork and because of its complex shape its construction cost is more as compared to other slabs, but it is more suitable to resist heavier and longer span loads and decreases deflection and vibration.

Waffle slab is preferred for span greater than 12m because it is much stronger than simple flat slab, flat slab with drop panel, one way and two-way slab.

Types of waffle slab

- One way waffle slab

- Two-way waffle slab

Ribbed slab construction

The waffle slab can be made by different ways. The difficult and complex task is to arrange formwork in such a way that it forms a grid pattern mold without any leakage and gap. After testing the formwork by Engineer the approval for concreting is given.

The formwork of waffle slab is made of many elements which includes

- waffle pods

- horizontal supports

- vertical supports

- hole plates

- cube junctions

- clits

- steel bars.

The construction of waffle slab can be occurred in three different ways, but its initial process is same

Precast slabs

In precast system the slabs are made in waffle panels form with the same construction technique. These types of structural members are mostly made in construction factories and then transport to site and then assembled.

In situ slabs

In In situ system the slabs are designed on construction site. First formwork is placed and then concrete is poured on it. After it attain suitable strength shuttering is removed and curing process continues.

Also Read: What is a stem wall – meaning – detail – benefits – design – procedure

Prefabricated Slab

In this system the reinforcement is installed while manufacturing concrete slabs. Then it does not need to reinforce the assembly on site. But the cost of this process is more than other two processes

Also Read: Rebar – Types of Rebar in Construction – Grades & Sizes – Properties [PDF]

Ribbed Slab Design

Various manuals and codes are available in the market which are written by world class institutes and are today followed for design of structures. Waffle slab parameters such as slab thickness and rib dimensions can be accurately determined by these codes. But there are some rules of thumbs as well which are explained below.

- As a rule of thumb, Slab overall depth is normally 3 in to 5 in thick (between 75 to 130 mm)

- The depth should be 1⁄24 of the span.

- The width of the ribs is normally taken 5 in to 6 in and ribs usually have steel rod reinforcements

- The distance between ribs should be typically 3 ft.

- The height of the ribs and slab beams should be 1⁄25 of the span between columns.

- The width of the solid area around the column should be 1⁄8 of the span between columns. Its height should be the same as the ribs.

Post-tensioning of slab panels

A Ribbed slab can be with or without post tensioning. It’s all your design preference. You need to evaluate your span and floor thickness requirements. A post tensioned waffle or joist slab is an economical solution for generous spans.

Post-tensioning strands can go along the joists in the longitudinal and transverse direction. However, it is not economical to post-tension the longitudinal joists.

The post-tensioning is only recommended along the slab bands between the two long sides of the structure. The profile of the tendons will go along the adjacent supports.

Also Read: Post Tension Slabs – Detail – Components – Advantages – Cost – Applications

Waffle concrete slab

Waffle concrete slab is a type of concrete footing system that is constructed on the ground. It is generally of 80 mm thickness and has edge or perimeter beam with intermediate ribs or beams running each way.

A concrete ribbed slab has polystyrene inside the voids between the slab beams. The foundation shows a waffle arrangement from the underneath. It’s a faster and cheaper type of footing. However, you need to evaluate your site condition and sloping situation. Waffle concrete slab is not a good choice for areas with cyclonic events or high wind areas.

Also Read: Continuous Footing – Detail – Diagram – 3 types (DETAILED GUIDE)

Advantages

Large span

The main benefit of this type of slab is large span and it is used for large span slabs and floors such as factories, halls, theaters etc. The span length limitation is one of the issues while designing one way and two-way slabs while waffle slab can be used for longer span because of its unique design and shape. It is preferred where there is limited requirement of number of columns.

Load carrying capacity

Waffle slab has greater load carrying capacity as compared to simple flat slabs and one way and two-way slabs. The greater load capacity of slab is because of its unique design and supporting ribs beneath the main slab. The ribs in combination with slab helps in supporting loads and increases structural rigidity of structure which also reduces vibration in structure.

Material for construction

Ribbed slab can be made of wood, steel and concrete depending upon the loading requirement and type of building. For small loads and lighter buildings such as garages the wooden material is preferred while for heavy loads and commercial buildings concrete waffle slab is recommended.

Vibration Control

The ordinary building structures having one way or two-way slab have vibration issues in case of large number of persons walking on it. It can also cause deflections. While waffle slab because of its structural rigidity and ribs beneath the slab decreases chances of vibrations. It is suitable for public office buildings and malls where large persons are walking at a time.

Economical

The construction of waffle slab requires less concrete as compared to one way and two-way slab for same design strength. The waffle slab designed in such way that it takes larger loads with less slab thickness requirement. So, the cost of construction also reduces and make the design economical.

Structural Stability

The waffle slab is in such shape which provides greater stability to structure as compared to other slab design and good for aesthetic appearance as well. It is constructed for hospitals, airports etc.

Disadvantages of Waffle Slab

Large formwork cost

The formwork for waffle slab is different from other slabs. Due to its complex shape different formwork tools are required which are costly and required in large quantity.

Require skilled Labor

Ribbed slab construction is complex and requires skilled labor as compared to simple flat slabs. The formwork construction and then checking of formwork needs skilled labor.

Require more height

Ribbed slab contains slab and ribs with suitable thickness and width which occupy space and reduces the floor height. By maintaining the suitable height of floor number of floors are reduced

Waffle slab vs flat slab

| Waffle slab | Flat Slab |

| It is stiffer and lighter slab | It is of made of full concrete, so it is a heavier system |

| It has a greater resistance against overall cracking | It can have shrinkage, plastic settlement, and overload cracks. |

| It is best for areas where slab vibration is an issue like in a hospital or laboratory | Flat slab needs additional reinforcement to resist vibration. |

| Waffle slab let you have open space without the need of intermediate columns. | This system has limited span allowance. |

| The construction may take more time. | It is typical slab system and so doesn’t need excessive time of construction. |

Is waffle slab cheaper?

Waffle concrete slab is a cheaper solution for your foundation system than typical raft slab or other types of slabs. It is also a better alternate for stem wall foundation system. All you need are void formers in the form of foam that helps create the voids between the ground slabs. Anyhow, in terms of durability and reliability, waffle slabs are as good as raft or any other foundation system.

What is the main disadvantage of waffle slab?

One of the main disadvantages of Ribbed slab is the need for rigorous supervision and skilled labor. As it is bit new technology, so it may not be an economical choice for large scale production.

Do waffle slabs crack?

Ribbed slab do have less overall cracking in terms of pure shrinkage or overloading cracks. Whether you have a conventional slab at-grade foundation or a waffle slab, plastic shrinkage cracking will be there in both the cases. All you can do is ensure proper curing of the slab during construction. Same stands true for plastic settlement cracking that is mainly due to poor compaction or wet concrete. In case of pure shrinkage cracking, waffle slab will have less cracking than conventional slabs as it allow free movement with less restraint by the ground.

Also Read: 9 Types of Concrete Cracks (With Pictures)- Tricks to Prevent – PDF

Is waffle slab strong?

Yes! Ribbed pod slab is enormously strong and durable. It not only reduces the building cost but also help create a strong structure that can go for decades without showing any signs of damage. Waffle slab system ensures greater stiffness and strength in comparison to conventional footing types.

Is waffle slab load bearing?

Because of greater strength and durability, the load bearing capacity of Ribbed slab is way too much than conventional concrete slab types. Its stiffness and strength allows to have large spans with less number of columns. So, it is a complete economic package for your house construction.