High Strain Dynamic Pile Testing or PDA Pile Testing is an alternate pile testing technique which takes less time for test preparation and conducting, compared to the conventional static pile load test.

This test method is used to obtain the force and velocity through measured strain and acceleration induced in a pile during the impact of an axial force. It is also sometimes referred as pile driving analysis test as it uses a pile driving analyzer (PDA) for the evaluation of the readings.

This test method is suitable for all type of deep foundation units i.e. pile or any other type of similar nature whether cast-in-situ or driven type.

PDA Pile Testing is usually performed for evaluation of bearing capacity and structural integrity of the pile foundation.

It provides the instant evaluation of quality for the piling system allowing the engineer to accept or reject the pile immediately.

Beside that some very useful and handy data is also obtained, which through experienced interpretation would develop trust of Client and Engineer on pile driving capability of Contractor. The added data obtained as a result of the test is:

- Maximum Stresses (Compressive and Tensile) occurring in the Pile

- Soil characteristics, such as soil damping coefficients and quake values.

- Performance of Hammering / Impact System

One of a very significant advantage of the High Strain Dynamic Pile Testing by PDA is its performance in non-destructive manner which not only save times but surely cut back the testing cost significantly.

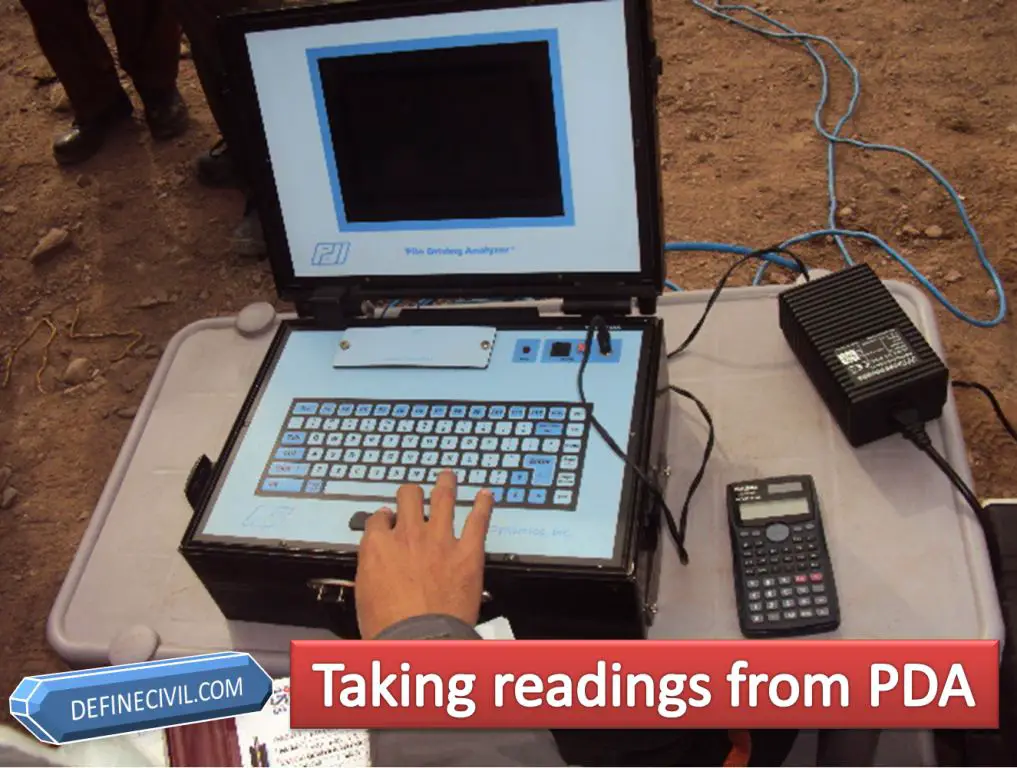

High strain dynamic pile testing is performed using Pile Driving Analyzer (PDA) together with strain Sensor and accelerometers. PDA is used to verify the mobilized capacity of all types of drilled and driven piles.

The Engineer, who is considered as the designer of the pile, is meant to analyze and interpret the result data of high-strain dynamic test so as to estimate the ultimate axial static compression capacity or simply the bearing capacity.

[su_box title=”Must Read”]Do you know the use of bentonite slurry in Pile foundation has countless benefits? Here is a very interesting guide stating all those benefits you can derive. Use of Bentonite Slurry in Pile Foundation[/su_box]

You can watch an interesting video guide I have made about High Strain Dynamic Pile Test here. You can also watch in on youtube. And please don’t forget to subscribe to our youtube channel.

https://youtube.com/c/saadiqbalengr

Factors Effecting PDA Pile Testing

Factors that may affect the estimated bearing capacity from dynamic tests (HSDT) include:

- Pile installation equipment and procedures,

- Elapsed time since initial installation,

- Pile material properties and dimensions,

- Type, density, strength, stratification, and saturation of the soil, or rock, or both adjacent to and beneath the pile,

- Quality or type of dynamic test data,

- Foundation settlement,

- Analysis method

- Engineering judgment and experience.

PDA (Pile Driving Analyzer) High strain dynamic test is recommended for piles with bearing capacity below 100 ton. For more than 100 ton Static loading test is recommended. For industrial buildings with bearing capacity of pile less than 100 ton can use HSDT. For high rise building with bearing capacity more than 100 ton Static loading test is recommended.

Dynamic measurements of force and velocity will be collected by the strain sensors and accelerometers attached to the pile. The PDA monitors the strain and acceleration caused by the hammer impact and processes these signals after each hammer below during driving or re-strikes to give immediate visual.

Results of Pile Driving Analyzer

The signals are digitized by PDA, results are computed and the data array of the signals for a low is stored.

The following PDA results are typically obtained on site:

- Mobilized Static load capacity based on CASE method

- Pile Integrity – location and extent of damage.

- Driving stresses –maximum compression / tension forces at pile top/toe

- Hammer performance-maximum energy transferred to pile.

Advantages of Dynamic Pile Testing by PDA

- Instant preliminary results on site

- Instant check on the pile integrity and the location of any damage.

- Feedback on maximum tension and compression forces

- Direct measurements of hammer input energy and efficiency

- Cost effective.

Static load tests are expensive and time consuming and therefore are often conducted only on a very small number of piles. With PDA many more piles can be tested at a much lower cost and faster speed. This improves quality assurance and helps to optimize pile driving criteria. PDA results also correlate well with the pile capacity obtained from conventional static load test and therefore confirms the structural integrity of the pile element.

“PDA is the answer for projects where static testing is prohibitively expensive or physically impossible”.

The prediction results of the static capacity from HSDT depend on the magnitude of penetration due to result of the impact. A permanent net penetration of as little as 2 mm per impact may indicate that sufficient movement has occurred during the impact event to fully mobilize the capacity. However, high displacement driven piles may require greater movement to avoid under predicting the static capacity, and cast-in-place piles often require a larger cumulative permanent net penetration for a series of test blows to fully mobilize the capacity. Static capacity may also decrease or increase over time after the pile installation, and both static and dynamic tests represent the capacity at the time of the respective test.

As the rating and correctness of of the test is directly dependent on the proficiency of the Engineer who is going to interpret the results of the High strain dynamic testing, so he must be qualified and proficient with expertise in wave mechanics, pile installation / driving methods, review of installation records. It is desirable that he should be well aware of the soil and its properties with its direct impact on pile driving.

The manufactures of the equipment offers training and seminars for the staff of the agencies willing to conduct the test at different projects.