A temporary framework to support a potentially dangerous structure or structure under repair is known as shoring. The word shoring means a timber or metal prop or pole renovators use to support or keep something in position.

Different types of shoring system offer lateral support to the walls. When walls bulge or split due to unequal foundation settlement or if repairs are required and a neighboring structure must be removed, and when apertures in a wall is required; expert use shoring.

You can utilize shoring in construction that is vertical, angled or horizontal; depending on the site situation and the type or support requirements. Civil engineers also use shoring during excavation to support the temporary steep sides of trenches. During renovation, you may have to relieve the load on a masonry wall while you make repair.

Also Read: Falsework – Types of Falsework – Applications – Components

Types of Shoring

-

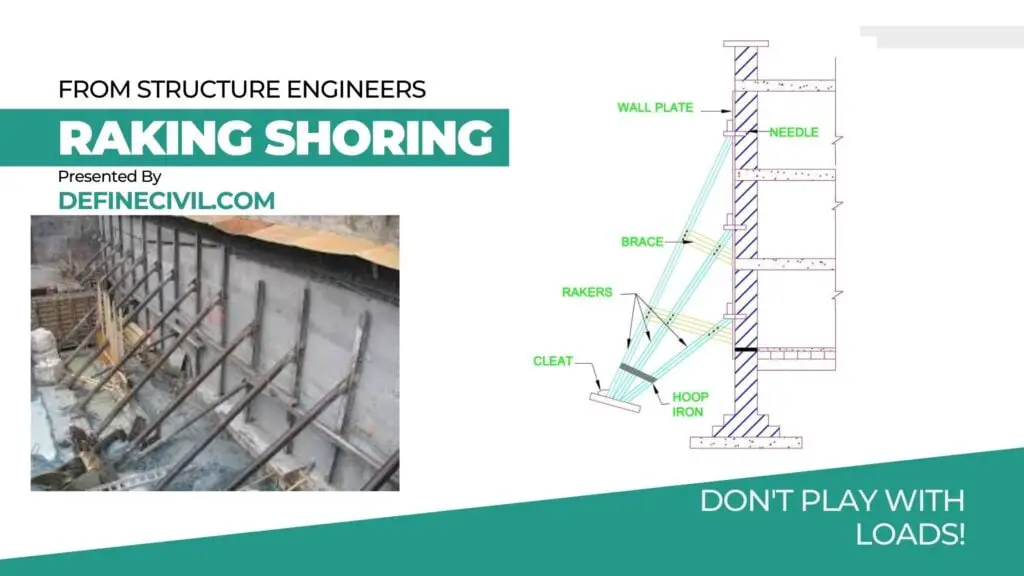

Raking shoring

In this case, rakers, or inclined members, are used to provide lateral support to walls.

-

Components

A raking coast is made up of the following elements:

- Members that are prone to rake or members that are rakers

- For the wall plate

- Needles

- Cleats

- For the sole, there is a bracing plate.

-

Component Specs

Popular wall plates range in size from 23cm * 5cm to 23cm * 76cm. The needles are used to secure the wall plates to the structure’s walls. These are normally 10cm * 76cm in size. The needles pierce the walls to a depth of about 10cm. The wooden cleats are also used to add more support to the needles. The needles are then rested against the sloped beaches’ upper ends.

The sole pieces are bedded at the base of the rakers at an inclined position in the ground to support the rakers. The rakers are attached to the soles with the help of cleats and dogs. If the ground is made up of soft soil layers, the sole pieces’ area must be enlarged in order to spread the pressure across a broader region. When there are a lot of rakers, hoop iron or bracing is employed to keep them together. The bracing is around 25 centimeters in thickness and 15 centimeters in width.

Also Read: What is wellpoint system? Types – Applications – Advantages

-

Points to remember

Important pointers for installations of raking shores:

- Rakers should be 450 degrees in the ground. In contrast, the angle might be anything between 450 and 750 degrees.

- The length of the raker can be shortened for tall buildings by using rider rakers.

- At regular intervals, rakers should be adequately braced.

- The size of the rakers will be determined by the projected wall push.

- At floor level, the raker’s centre line and the wall should meet.

- To cover a longer length of bar, shoring can be spaced at 3 to 4.5m intervals.

- The sole plate should be properly implanted in the ground with the suitable section and size on an inclination.

- When exposed to vibrations, wedges should not be utilised on sole plates since they are prone to buckling.

-

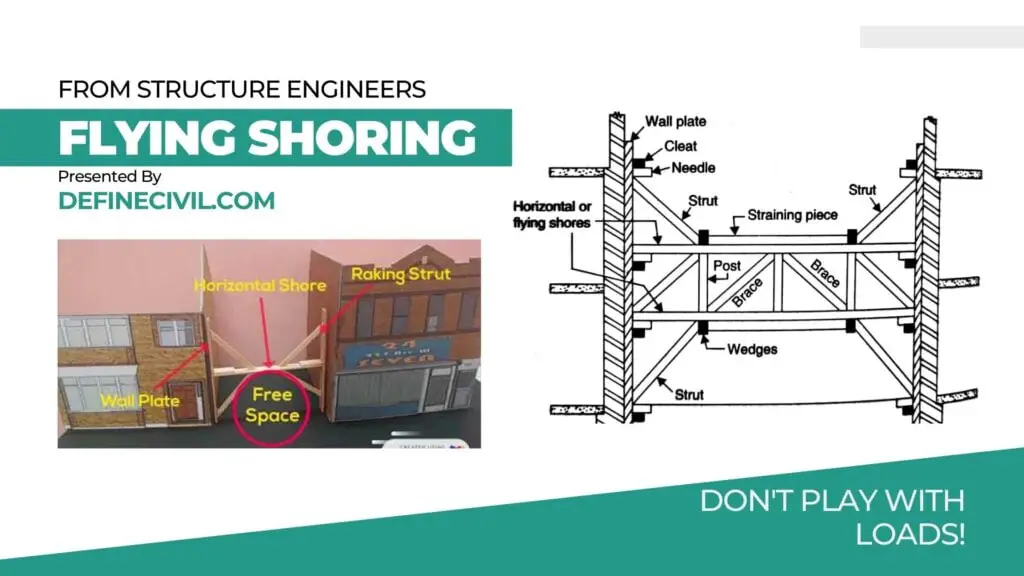

Flying shoring

Horizontal shoring is referred described as “flying shoring.” Shoring is used to provide temporary support for the party walls of the two buildings while the intermediate structure is destroyed and rebuilt. This type of shoring includes all strategies for supporting an unstable structure where the coastlines do not reach the earth. The term “flying shoring” was invented as a result. The beach that was used for this was known as the “flying shore.”

-

Components

The following are the major components of a flying coast:

- To begin, there are plates for the walls.

- Needles

- Cleats

- Horizontal Struts (also referred to as the horizontal shores)

- Inclined struts

The wall plates are put against the wall and securely fastened to it in this sort of shoring. The slanted struts are supported by a system of cleats and needles.

The needle at the top and the straining piece at the bottom support the inclination struts. A straining sill is another name for this type of straining component. Typically, it is spiked to the horizontal coast.

The strut’s width and the stressed piece’s width are the same. When the distance between the walls to be strutted apart is significant, a trussed framework of members will be employed to act as a flying sore.

Also Read: Caisson Foundation – Types

-

Method

In a nutshell, the following is the method for creating the flying shore:

- The ground is prepared before to the installation of the flying beach so that measurements and angles can be taken into account.

- The cleats are then fastened to the wall plates. The first pair adds to the strength of the struts by providing additional support for the horizontal shore.

- The horizontal beam close to the surrounding wall’s cleat must be large enough to support the wedges while allowing for an appropriate beam overlay.

- At both ends of the horizontal beam, an equal cleat-bearing surface must be provided.

- The struts must then be joined at a 45-degree angle to the horizontal beam. The straining pieces must be used on the horizontal beam to keep the struts apart. The length of such straining parts is governed by the horizontal beam’s length.

- Folding wedges are put between the shore and the wall plate to secure the horizontal beams and straining pieces to the centre cleat.

- Finally, the struts are connected between the top half of the lower cleats and the lower struts’ lower struts’ lower struts’ lower struts’ lower struts’ lower struts’ lower struts’ lower struts’ lower struts’ lower struts’ lower struts’ lower struts’ lower struts’ lower struts’ lower struts’

Also Read: 14 Types of Columns in construction

-

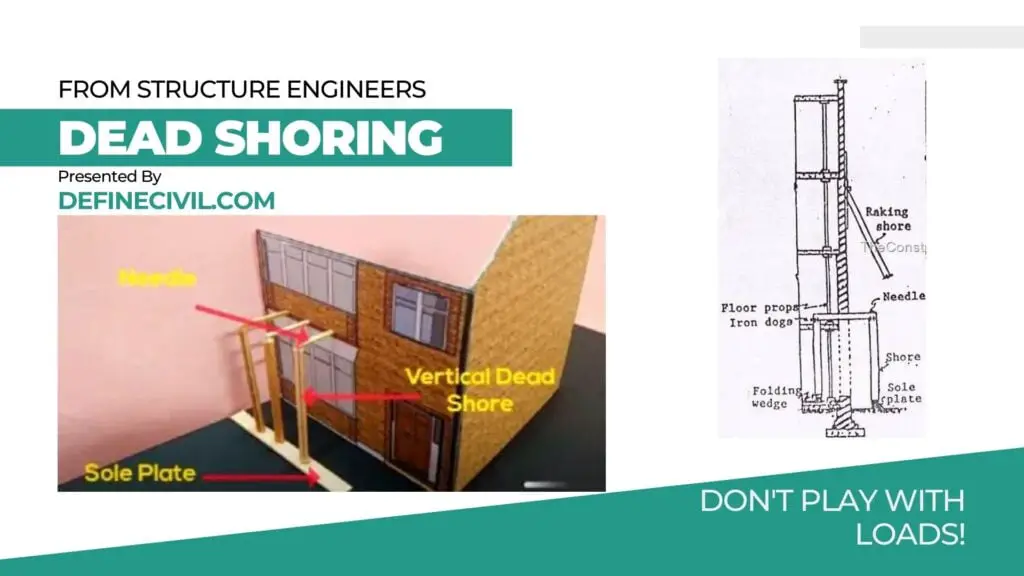

Dead shoring or Vertical Shoring

Dead shoring is also known as vertical shoring. It is the most popular type of shoring used to provide support to walls, roofs, floors, and other buildings, particularly when the lower portion of a wall has been removed to allow an additional entry or to replace a broken load-bearing wall. “Dead shores” refers to the coasts used for such activities. A network of pillars and beams support the lifeless beaches. These are needed to support the whole structure’s weight and distribute it to the ground beneath the foundation.

When cutting holes in an existing wall, the holes are made at a height that allows for the installation of the beam or girder that will permanently support the weight of the structure above.

The time it takes for such holes to form is determined by the masonry structure. The average separation is between 1.2 and 1.8 metres.

The needle beams are then put into the cut holes and supported by the dead shores at their ends on either side of the wall.

Depending on the use, the needles might be made of steel or wood.

When the supports and needles are in place, the dead beaches on either side of the wall are moved away from the wall to make room for operations.

The props are held in place by dogs, while the connection between the prop and the needle is held in place by folding wedges at their bases.

Raking shores are typically made before the operation for safety reasons, as wall cutting can produce vibrations and shocks.

If a raking system is used, it should only be removed once the entire dead shore system has been removed.

Also Read: Load Bearing Wall vs Non-load Bearing wall – Cost

Cost of Shoring

For most obvious uses of shoring in excavation; the cost of shoring will depend on

- type of shoring

- Depth of excavation

- Type of soil anchors

For most common excavation projects; you can expect to pay anything around $30 to $80 per square foot. An alternate to shoring will be to go by making slopes along the sides. But it is worth mentioning that making slopes along the sides costs more than renting a trench shield or shoring equipment.

You may also need to use shoring in residential construction excavation for protecting the property of neighbors. The shoring will protect your neighbor’s house from collapse and will hold the earth back in the excavating section.

For such, you need to use arrangement of props, beams, or posts to support and retain the earth. For shoring piles, the cost is around $4,000 per pile. You may need to have a pile every 6 to 10 feet.

Requirement of shoring during excavation

Here’re some of the cases where you need to use shoring during excavation:

- During excavation for a residential construction that is deeper than the footings of a neighboring house or structure;

- For excavation that is close to the property line, deeper than 4 feet but can’t be properly sloped 45 degrees.

- When walls bulge or crack due to excessive pressure and require additional support.

- Bad soil conditions (but especially in Type 3 and 4 soil quality)

Also Read: Hydrovac Excavation – The process – Benefits and Applications