If you’re bit concerned about quality of freshly mixed concrete, you’d be dealing with terms like slump of concrete, consistency, fineness of cement, and compressive strength. Of all, slump of concrete is an important quality control parameter. The next time you step in as incharge of concrete pouring activity, you should know different types of concrete slump. You need to make sure the concrete slump falls in the range set for your project.

What is concrete slump?

Concrete slump is a figure that defines the workability of the fresh concrete mix. The term workability relates well with the concept and requirement of the consistency of the fresh concrete mix. Civil engineers often use terms like workability and consistency to define the flow-ability of fresh concrete.

Flow-ability is an important consideration for concrete pouring activities. The slump of concrete you will design for the rigid pavement would be way less than that you will design for a heavy reinforced concrete column.

Do you know, the slump of concrete dictates the compaction requirement of the concrete?

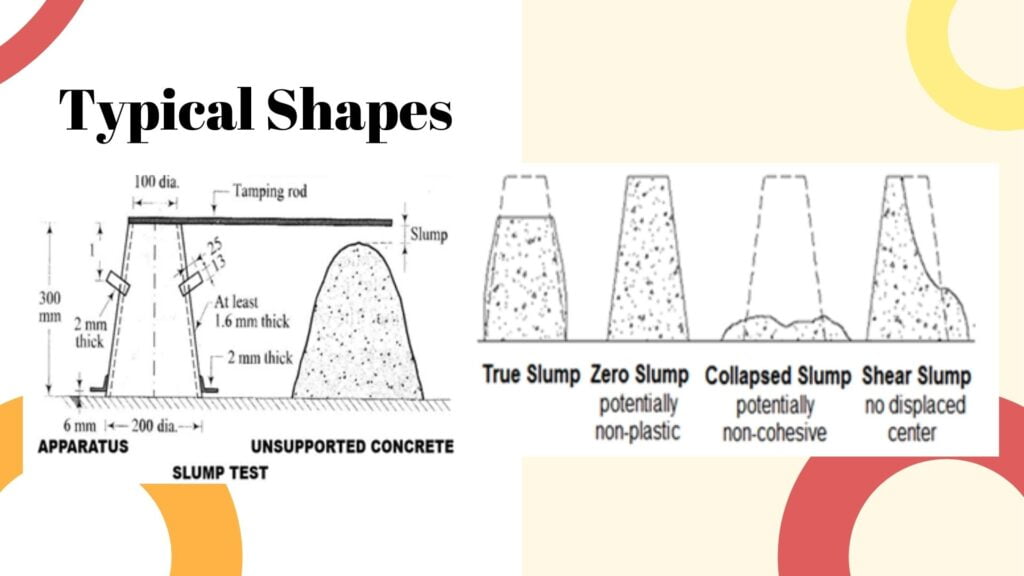

Concrete slump is the value that defines the fluidity in the fresh concrete mix. It is measured by slump cone test at the time of batching and placing of concrete. All you have to do is to pour the concrete mix in a slump cone in layers properly compacted. Afterwards, you will find difference in height of unsupported concrete and that of the standard cone. The slump value is noted in inches/millimeters.

Do you know – the height of a standard slump cone is 30 cm with top diameter of 10 cm.

Concrete is widely used in many construction purposes so, the requirement of slump in the mix designs of the concrete is different for every specific purposes.

Why you need to test slump of concrete?

- To ensure adequate mixing of concrete ingredients while batching.

- To ensure the concrete is workable and flowable during concrete pouring in forms.

- To meet the requirements of the compaction of concrete around congested reinforcement and tight corners.

The fresh concrete mix is tested for the consistency or workability by following the standard tests method for slump of hydraulic cement concrete ASTM C 143.

Do you know – beside slump cone test there’s another test for workability of concrete? – that’s called the compaction factor test.

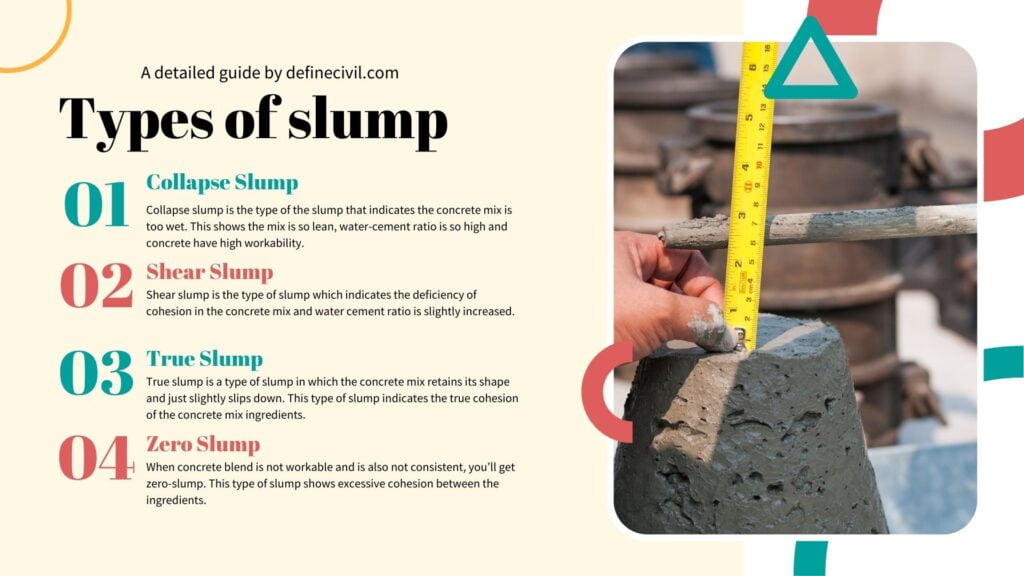

Types of concrete slump

As the freshly concrete mix is being poured, the flow-ability of concrete is verified by performing the slump cone test.

When the slump cone is filled in layer with the fresh concrete mix, the unsupported concrete makes different shapes according to the profile of the concrete.

The different types of profile for the concrete are named as:

- Collapse slump

- Shear slump

- True slump

- Zero slump

Collapse slump

Collapse slump is the type of the slump that indicates the concrete mix is too wet. This shows the mix is so lean, water-cement ratio is so high and concrete have high workability. The perfect example of collapse slump is that of self-compacting concrete.

Do you know- Self compacting concrete has a slump value of more than 650 mm.

Beside intentional use for specific application, the reason for collapse slump can be :

- Concrete mix is not properly mix.

- Water cement ratio is so high that the concrete is highly workable.

- This type of slump is not recommended in any type of the concrete mix design.

- It is inappropriate for normal applications.

Shear slump

Shear slump is the type of slump which indicates the deficiency of cohesion in the concrete mix and water cement ratio is slightly increased. If one-half of the concrete in slump cone slides down in an inclined plane the slump is called as shear slump.

The slump is also not preferred and concrete mix is remixed for the legitimate results. This type of slump indicates that the concrete mix is not properly mixed and there should be remixing of the concrete to obtain the adequate results.

If the shear slump is repeatedly obtained, then you need to manipulate the mix design to enhance cohesion between the ingredients. So, if you use the concrete with shear slump there’d be problems like bleeding. Moreover, there will be cracking failures in structures.

True slump

True slump is a type of slump in which the concrete mix retains its shape and just slightly slips down. This type of slump indicates the true cohesion of the concrete mix ingredients. True slump is obtained when concrete mix is prepared with full consistency.

This type of the slump is desired in all the type of concrete constructions.

Also Read: Concrete Retarders – Disadvantages – Types – Uses – Price

Zero slump

When concrete blend is not workable and is also not consistent, you’ll get zero-slump. This type of slump shows excessive cohesion between the ingredients. Such a concrete is not easy to pour or work with at site.

This type of slump is also not preferred in most concrete structure. However, with slight adjustments you can convert this slump into the other types. One of the useful characteristic of the true and zero slumps is that you can transform them into shear and collapse slumps.

Figure 1, for collapse, shear, true and zero slump is shown as

Typical values of the concrete slump and its uses.

| Degree of workability | Slump | Compacting

Factor |

Type of mix |

Uses in construction | |

| mm | in | ||||

| Very low | 0-25 | 0-1 | 0.78 |

Very dry mixes |

1. Pavement constructions.

2. Roads vibrated by power operated machines. |

| Low | 25-50 | 1-2 | 0.85 |

Low workability mixes |

1. foundations with light reinforcement.

2. Parapet, slab, beams, columns, piers, and walls 3. Roads vibrated by hand operated Machines. 4. Mass concrete |

| Medium | 50-100 | 2-4 | 0.92 |

Medium workability mixes |

1. Manually compacted flat slabs using crushed aggregates.

2. Normal reinforced concrete manually compacted. 3. Heavily reinforced sections with vibrations. 4. Concrete for canal linings 5. Retaining walls |

| High | 100-175 | 4-7 | 0.95 |

High workability mixes |

1. Sections with congested reinforcement

2. Not normally suitable for vibration |

Effect of slump on the concrete

Slump, being property of fresh concrete-mix depends a lot on the water-cement ratio. The ratio of mass of water to the mass of cement is termed as water-cement ratio. Civil engineers write it as “W/C”. The typical value is around 0.40 to 0.60.

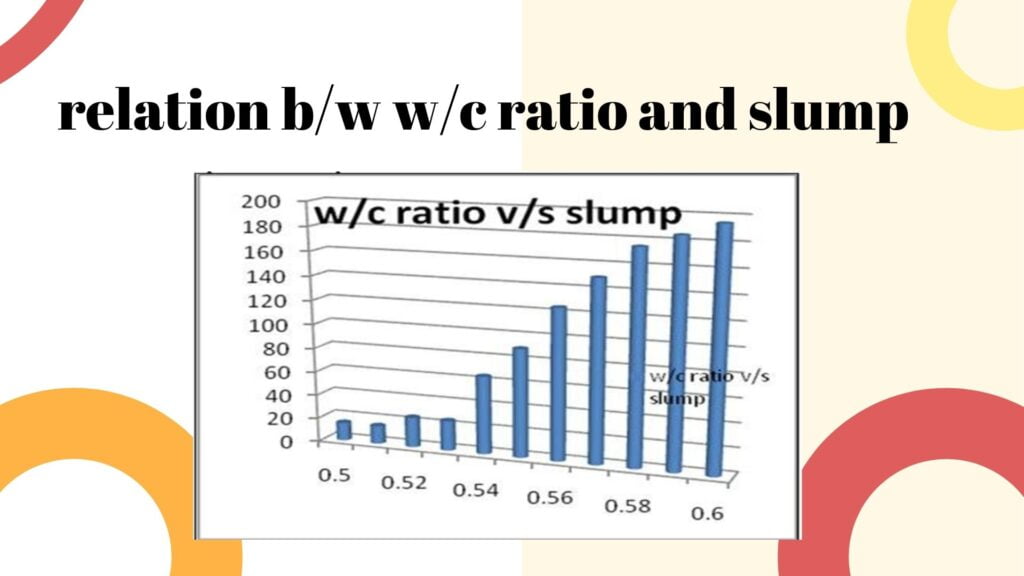

Workability and slump of concrete is directly-proportional to the water-cement ratio. So, you can assume that for zero or true slump, you need a lower value of water-cement ratio. The lower value of w/c means more cement and less water. On the other hand, a higher value of w/c ratio will give you more workability.

The water/cement ratio vs slump graph is shown below

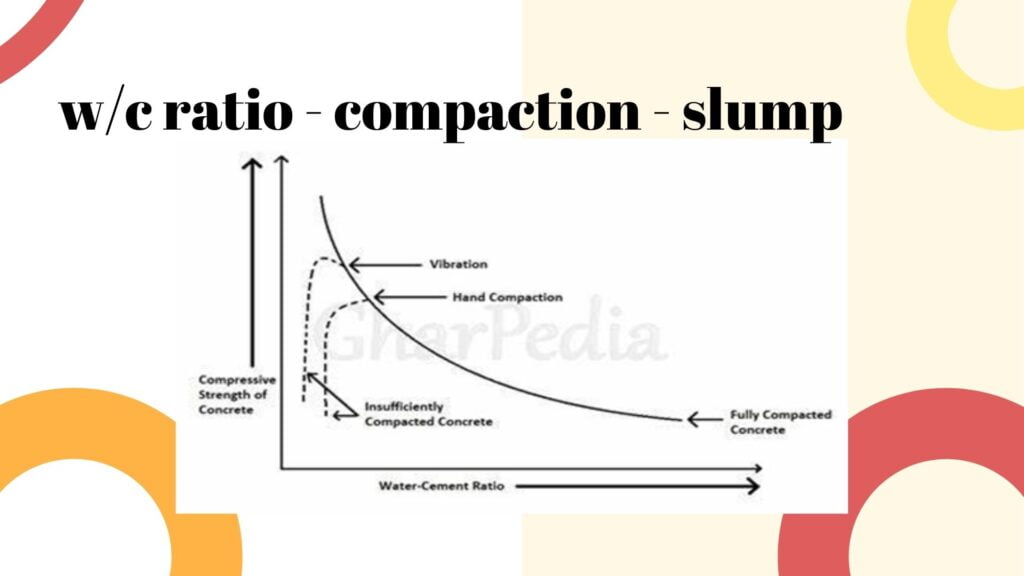

The water/cement ratio also greatly affect the strength of the concrete explained in following graph:

The above graph shows that the compressive strength of the concrete is decreasing as the water/cement ratio is increasing.

Slump also impacts the mechanical properties of the concrete. As lessor the w/c ratio means or lower the slump the higher will be the concrete mechanical properties. That is why the true slump, and lower or moderate water/cement ratio is recommended in the concrete for the construction purposes because, it provides the ultimate strength to the concrete.

Factors effecting the slump of conccemenrete

Following are the factors that impact the slump of the concrete:

- Water cement ratio: The more the water-cement ratio, the more the slump. The water decreases the friction between filler aggregates. As a result, the ingredients get a slipping effect that results in more slump value.

- Aggregate: The grading of the aggregate and the shape / angularity or the surface texture greatly impacts the flow-ability or slump of the concrete. The absorption capacity of the aggregate also impacts workability.

- Temperature: You know during pouring of concrete, a higher temperature is not preferable. A higher temperature not only evaporates the water in the concrete mix but also elevates the temperature during hydration reaction. So, at higher temperatures you’ll get lower values of slump.

- Fineness of cement & aggregate: Finer the aggregates, the more surface area and water requirements and thus lower values of slump are achieved.