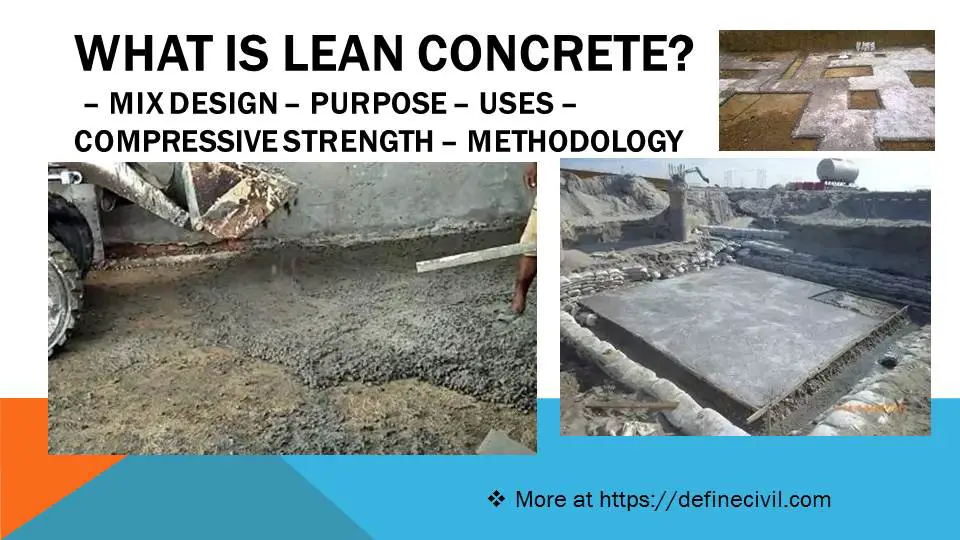

So, you’re wondering what is lean concrete? Well, concrete mix made from lean concrete is low in cement and high in aggregates. It is used for several purposes, such as blinding concrete under foundations and leveling pads below footings.

We call lean concrete “not rich.” That’s because it is not rich in cement. Cement is a costlier component of concrete.

What is lean concrete?

Here’s the definition of lean concrete:

Lean concrete refers to a mix where the cement used is less than water. Concrete with a high ratio of aggregate to cement is called lean concrete.

Technically, the mix is called lean concrete mix if its cement content falls below 10 percent.

Concrete bends more if the aggregate/cement ratio is higher. Because there is less paste available to provide smoothness and aggregates per unit of surface, aggregates have lower mobility.

India’s current construction practices for rigid pavement require a layer of dry lean concrete, abbreviated (DLC). This course acts as a base layer on which concrete slabs of pavement quality are placed.

DLC base course is used to construct even the municipal’s concrete roads, including white-topping. DLC is mainly made with regular Portland cement according to Indian Road Congress specification SP 49: 1998. IRC SP-49: 1998 recommends using Portland pozzolana and portland cement (PSC) in the production of DLC. You will find PPC common in India on a broad scale, but it has different properties than OPC.

The purpose of lean concrete

To seal the soil and create a level surface for building foundations, a layer of concrete, usually 5-10 cm thick, is placed on top of it.

For example, fine material, e.g., Sand, is used to fill in cracks on a pavement or earthworks layer.

Mix Ratio of Lean Concrete

The concrete ratio is 1 to 3:6 (M-10) for Civil construction. Below, concrete is known as lean concrete.

For lean concrete mixes, the ratio is generally 1:3:6, 1:4:8, and 1:5:10.

Mix for lean concrete examples:

- Grade of concrete (M-5); 10 (cement sand aggregates) The M-5 grade concrete will have a characteristic strength of 5 MPa.

- Grade of concrete (M-7.5) – 1:4:8 (cement, Sand and aggregates). M-7.5 grade concrete will have a characteristic strength of 7.5 MPa.

- Grade of concrete (M-10) – 1:3:6 (cement, Sand and aggregates).M-10 grade concrete will have a characteristic strength of 10 MPa.

Thickness of lean concrete

Here’s a recommended value of lean concrete in various structures:

- Dam and water retaining structure foundations = 75 mm.

- For foundation on rough or harsh conditions, thickness = 100 mm.

- For small structures like septic tank and sewerage manhole thickness = 50 mm

- For isolated foundation of a building thickness = 75 mm.

- For pad or raft foundation thickness = 50mm

Compressive Strength of lean concrete

- M-5 grade concrete will give a total characteristic strength of 5 MPa.

- M-7.5 grade concrete will give a total characteristic strength of 7.5 MPa.

Advantages of lean concrete

- Lean concrete creates a uniform foundation surface and protects it from direct contact with soil.

- We use the lean concrete mostly under the foundation to protect our slab. The level surface also helps in fixing reinforcement. The bottom rebar of the foundation slab requires a good amount of cover to avoid rusting.

- It creates a solid concrete foundation that you can easily reinforce with steel.

- It avoids direct contact between foundation concrete and soil.

- It protects the main foundation from ground below. Moisture and other chemicals such as phosphates can cause concrete to crack or become weaker.

Construction Methodology

Here’s the procedure of laying lean concrete:

- Compact the underlying surface to within 13mm 1/2in the finish grade and elevations as shown in drawings before placing lean concrete.

- To ensure that the concrete is in a moist and firm condition when placed, wet the underlying material before placing lean concrete.

- You must not allow any equipment other than lean concrete delivery and paving equipment to be installed on the prepared underlying material. Protect the underlying material against frost in cold weather. Use no chemicals to remove frost.