Apart from the normal shrinkage cracks in concrete due to hydration, there’re different types of concrete cracks that one must know. Some of these cracks are critical where others are hairline cracks that you don’t always have to repair.

So, it is critical to understand the most common causes of cracking in concrete and how you should fix.

Although concrete is not immune to cracking.

As long as the hydration reaction happens, the concrete starts setting. With such, the drying and shrinkage results in hairline cracks. We should look for ways to stop concrete cracking.

Curing is critical at this stage. Either you can spray water through hose or apply water-soaked hessian or jute cloth. Anyhow, it is crucial to continue curing till 7 days of the concrete pouring.

Structural cracks in concrete

As per the American Concrete Institute Manual, ACI 302, 1-40 – that summarizes as:

Even if you’ll employ best floor designs and construction procedure, you can’t achieve a crack-free and curl-free flooring surface.

So, all designers and contractors tell homeowners that some amount of cracking and curling is fair. There’s no adverse issue on the floor’s quality.

Anyhow, still you’d need to be sure when to worry for cracks.

What is crack in concrete?

Here’s how we define a crack in concrete

Thin hair lines with varying thickness of micro to millimeters, running horizontally, vertically, or diagonally in a concrete structure is known as cracks in concrete.

These cracks are considered dangerous if their thickness is increasing with time. Usually, crack with the width less than 0.3mm is considered acceptable but with the thickness more than 0.3mm affects the durability of structure.

There are many reasons for originating cracks in concrete which is discussed as below:

- If stress produced in a structure is more than its strength it will cause cracks in concrete structure.

- Concrete expands or shrinks with the rise or fall in temperature. If no accommodation or provision is provided to counter-fall expansion or contraction it will results in cracks in concrete structure.

- Cracks also develop in structure because of settlement in foundation.

- If proper curing is not done after concreting it will also result in cracks.

There are following types of concrete cracks.

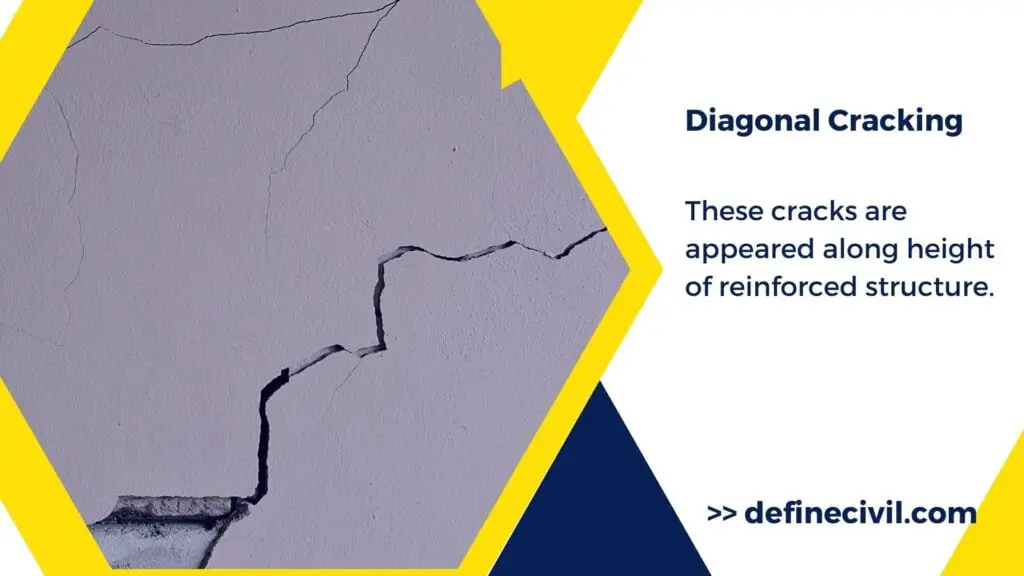

Diagonal Concrete Cracks

These cracks are appeared along height of reinforced structure. This crack includes entire face of structure. This type of crack originates because of insufficient loading capacity, insufficient cross-section, or insufficient reinforced steel.

See Also: Rebar – Types of Rebar in Construction – Grades

Horizontal Concrete Cracks

This type of crack appears at the junction where beam and column are connected together. It moves horizontally along the structure. It is generated because more tensile stresses, uniaxial bending, inadequate shear strength, and inadequate reinforced steel.

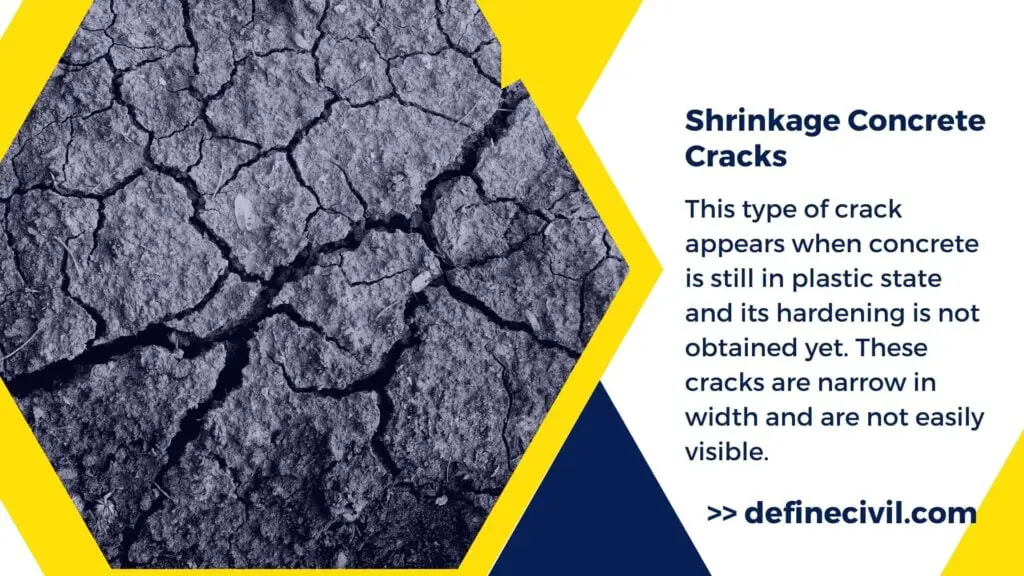

Plastic Shrinkage Concrete Cracks

This type of crack appears when concrete is still in plastic state and its hardening is not obtained yet. These cracks are narrow in width and are not easily visible. Anyhow, these cracks exist on the surface and extend throughout the thickness.

Also Read: Properties of Hardened Concrete

To your understanding, a concrete in plastic state is full of water. Now when this water evaporates or gets escapes from concrete it leaves void air spaces in concrete structure that makes concrete weak and originates cracks in it.

These types of concrete cracks are more common along corners or along the circular objects protruding from the surface like pipes, plumbing fixtures, or drains. The reason of shrinkage crack there is because of the blockage along corners.

Also Read: What is Water Cement Ratio?- Guide

Excess water in the concrete mix is the main reason for shrinkage cracks. So, you must not allow labor to add more water at site during pouring. Labors typically do that to increase the workability. As such a workable concrete is easy to pour and level. But too much water can leave more void spaces resulting in more shrinkage cracking. Another common reason of shrinkage crack is hot weather and improper curing.

Anyhow, we can control the shrinkage cracks by using adequate water just enough to satisfy hydration. Apply control joints into the slab to prevent shrinkage. Use cold aggregates or even ice if the temperature is too high.

Pro tip – Try to ensure the aggregate storage pits are fully covered and keep the surface of transit mixer fully covered by water-soaked cloth.

As per concrete experts, the best temperature for concrete pouring is around 40 to 60°F. As Per ASTM C 1064-86, a maximum limit of concrete temperature is 27 to 35 °C.

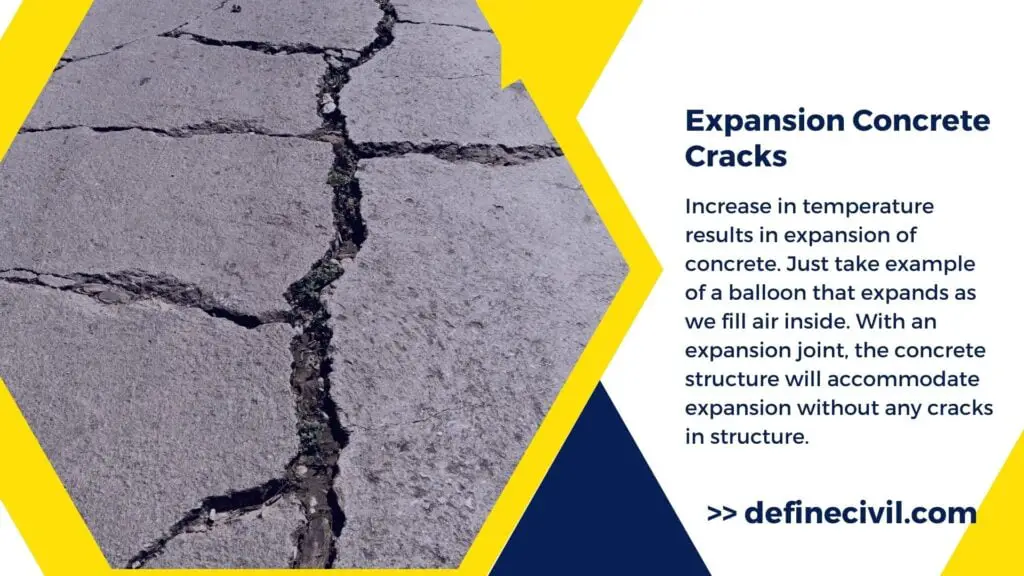

Expansion Concrete Cracks

Increase in temperature results in expansion of concrete. Just take example of a balloon that expands as we fill air inside. With an expansion joint, the concrete structure will accommodate expansion without any cracks in structure.

Also Read: How to grind concrete smooth?

While, if expansion joints are not provided or their expansion is restricted it will result in cracks known as expansion cracks.

Along with control joints, we provide expansion joints in concrete. It is a gap that allows the concrete to expand or even contract as and when temperature changes. It allows concrete patches to move without causing stresses.

Concrete slabs do need expansion joints. The expansion joint are provided no farther apart than 2 to 3 times in feet the total width of the concrete (in inches).

So, for a 6 inch concrete slab, there must be expansion joint no more than 12 or 18 feet apart i.e. 6 x 2 = 12 or 6 x 3 = 18.

The depth of the joint has to be at least a quarter of the thickness of the slab.

We use pliable material in concrete like (asphalt coated, cork, or plastic foam).

Shrinkage Concrete Cracks

As, like expansion cracks, shrinkage cracks also appear because of fall in temperature.

Crazing Concrete Cracks

It includes fine random cracks or fissures on surface of concrete which appears because of shrinkage in concrete. These cracks appear after first week of concreting and these cracks do not affect integrity and durability of concrete structure.

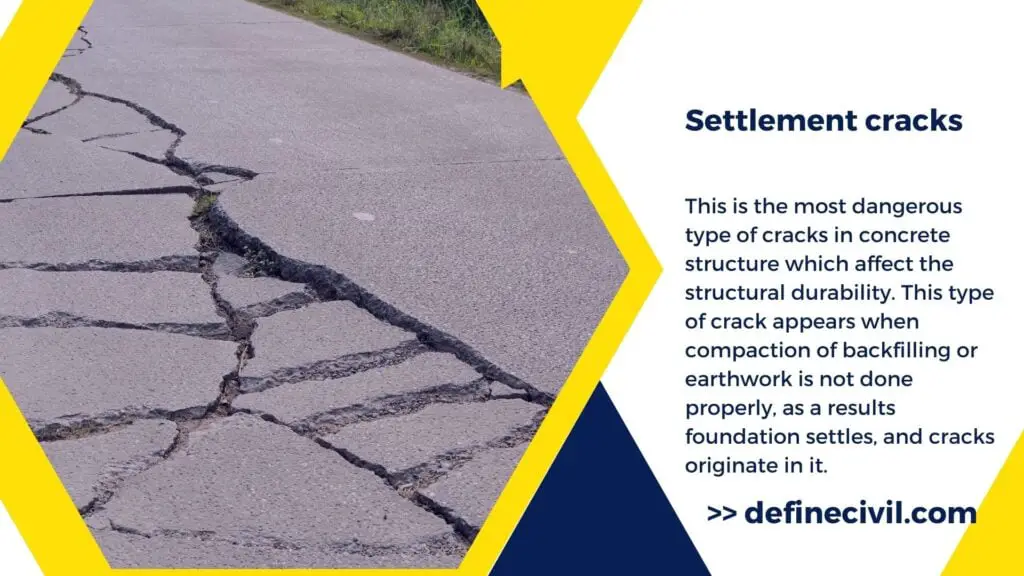

Settlement Concrete Cracks

This is the most dangerous type of concrete cracks structure which affect the structural durability. This type of crack appears when compaction of backfilling or earthwork is not done properly, as a results foundation settles, and cracks originate in it.

Freezing and Thawing Concrete Cracks

This is also dangerous type of crack which occurs because of presence of water in void of concrete. We also refer to these concrete cracks as heaving cracks.

As, temperature get reduces the water freezes inside concrete freezes and increase volume up to 9% which causes rupture and increase in tensile stress in concrete structure, Similarly, with increase in temperature this water melts with decrease in volume. Thus, with the change of temperature freezing and thawing cycle occurs and results in origination of serious cracks.

Overloading Concrete Cracks

If the load on concrete structure exceeds the given design load it will results in increase in stress compared to strength which results in formation of cracks known as overloading of cracks.

How to avoid cracks in concrete?

So, you see it is fairly difficult to evaluate and determine the main reason behind different types of concrete cracks. But when you can identify the cracks of concrete; you can ascertain the reason and remedial measures. Anyhow, you can avoid worrisome cracks in concrete by ensuring following:

- Proper site preparation – Make sure the concrete pour is free from any debris or trash as it can result in structural cracking. Evaluate the structure and utilities to make sure the base for concrete pour is of good quality and can have a proper bond. For direct pouring concrete on ground or soil, we normally provide polythene sheet to avoid moisture loss from the mass.

- Quality mix – Make sure you strictly follow the mix design and avoid unnecessary filling of water in the pouring concrete.

- Good finishing practice – A proper finishing surface is critical not just for aesthetic purpose but also to avoid structural damage to the concrete matrix. You can use a float to screed and darby the concrete right away. By taping and pushing the concrete surface with float, you’ll have water on the top but make sure the water disappears entirely.

- Proper compaction – In order for the concrete to reach its full design depth, compaction is a critical process. The strength, density, and low-permeability is only ensure when compaction is done correctly.

Also Read: Construction Tools Names and Their Uses Complete LIST [50+]

The bottom line

I hope you’d like the article about types of concrete cracks and it’ll be a helpful resource for your profession. Don’t forget to share and common below.