A rigid pavement, as the name implies, is a type of pavement that stays like a rigid slab under the loading. The rigid slab bridges the low-bearing or poor compacted soil. So, rigid pavement is an ideal pick if you have poor bearing soil or the loading is heavy.

Normally, civil engineers construct rigid pavement with un-reinforced or plain cement concrete. But in cases where loading needs more flexural strength or there are chances of temperature cracks, we can provide reinforcement mesh in both ways of the slab.

The type of the pavement offers high overall flexural strength. It turns out as a durable and long-lasting wearing surface with strong base. Upon loading, rigid pavement deflects very little due to high modulus of elasticity of the concrete.

That is the reason why most of the pavements for truck lanes or HTV type traffic make use of rigid pavements instead of the flexible pavement.

Rigid Pavement Layers

The typical details of the rigid pavement include:

- A subgrade

- Lean concrete (only for reinforced rigid pavement)

- Top wearing surface

For designing the rigid pavement, you have to estimate the thickness of the slab depending on the density of traffic and normal loading conditions. The designer has to play around thickness of the slab as well as the mix design or compressive strength of concrete.

See Also: Camber in road construction, Types, and Advantages

Stresses in rigid-pavement

The load-carrying capacity of the rigid pavement is because of the rigidity or high modulus of elasticity. So, the design of the rigid pavement deals with two basic types of stresses.

- Stresses due to loading condition – We can calculate wheel load stress with the help of Westergaard’s equation for stress. We normally do that for three critical locations i.e. interior, edge, and corner.

- Stresses due to temperature changes. It is further divided into two types of stresses

- Warping stresses – Due to daily variation of the temperature, the top and bottom of the slab has different temperatures. This results in warping action of the slab causing warping stress.

- Frictional stresses – This type of stress is mainly due to overall increase or decrease of temperature of the slab due to seasonal variation.

Design of rigid pavement

You can decide to use C30 concrete having 28 days cylindrical compressive strength of 30 Mpa and your required slab thickness comes out as 200 mm. If you want to reduce the thickness of the slab, you might have to increase the compressive strength or provide a steel mesh to provide necessary flexural strength.

Also Read: Curb and Gutters – Details

For the exact design of pavement steps, I’m going to add a dedicated section in my website, so stay tuned for that. If you’re still keen to know, here’s a design guide.

Now, let’s proceed with the introduction to rigid pavements.

TYPE OF RIGID PAVEMENT

Experts classify rigid pavement depending on the reinforcement into following categories:

- Reinforced concrete rigid pavement

- Jointed reinforced concrete pavement

- Continuous reinforced concrete pavement

- Un-reinforced concrete rigid pavement

See Also: Different Modes of Tranportation

-

Reinforced concrete rigid pavement

The type of the pavement in which we provide reinforcement bars mesh is termed as reinforced concrete rigid pavement. It is further classified into following types:

- Jointed concrete reinforced concrete pavement (JRCP)

- Continuous Reinforced Concrete Pavement (CRCP)

-

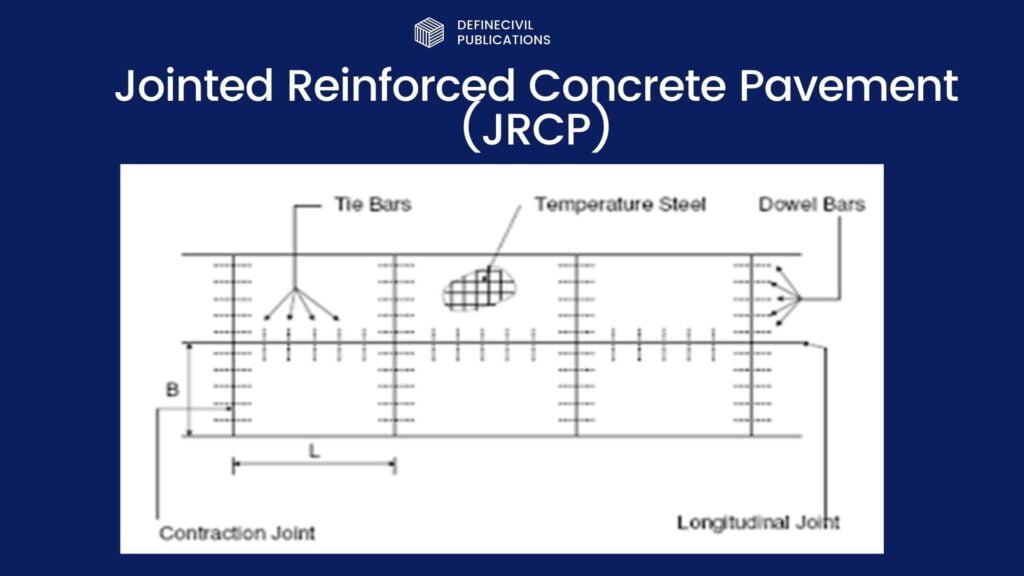

Jointed Reinforced Concrete Pavement (JRCP)

Jointed reinforced concrete rigid pavement has transverse joints placed at mid height and discontinued at the joints generally spaced at 9 to 12 meters apart. The purpose of the reinforcement is to protect the rigid concrete slab against development of transverse cracks and transfer the load over a wide area of the pavement.

It can be used for low or medium traffic. The use of reinforcement is only to control the cracking in the rigid concrete slab rather than other structural purposes in the pavement.

-

CONTINUOUS REINFORCED CONCRETE PAVEMENT (CRCP)

This type of rigid pavement in which the reinforcement is used in the whole pavement rather then mid height or the along the joints. The main function of providing the steel meshes for controlling the longitudinal cracking in the rigid concrete slab.

- This type of rigid pavement is very costly and often used and used where the higher traffic and busy roads.

- This type of pavement provides much strength to the sub-grade of the pavement where the sub-grade is poorer.

- This is so strong and can bear heavy loadings

- Used where adverse weathering conditions of the environment.

Use of the continuous reinforcement in the rigid pavement as;

-

UN-REINFORCED CONCRETE RIGID PAVEMENT

The type of rigid pavement in which no reinforcement is used is called un-reinforced/plain concrete pavement. It is divided into two types as:

- Jointed plain concrete rigid pavement (JPCP)

- Plain concrete rigid pavement

-

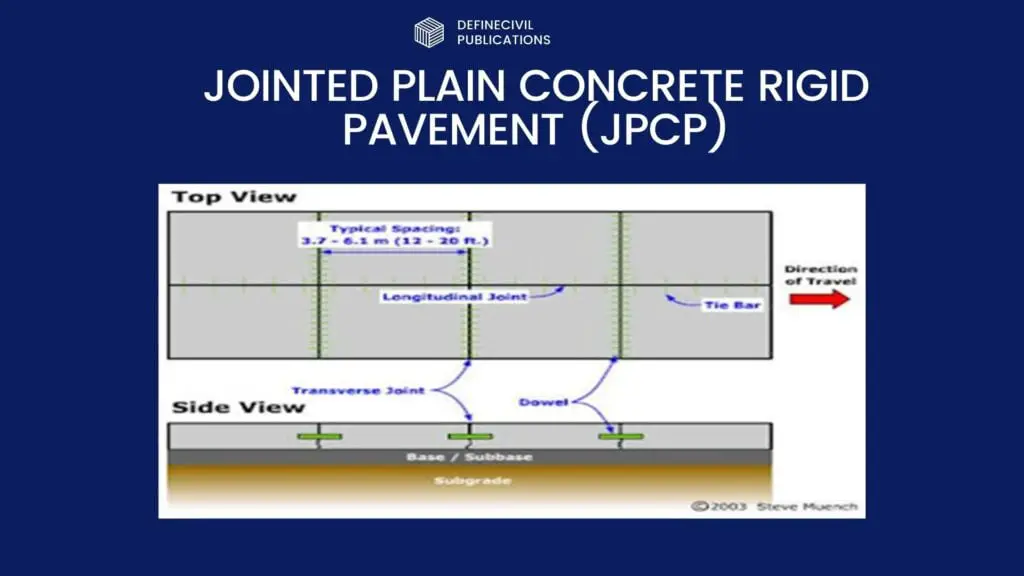

JOINTED PLAIN CONCRETE RIGID PAVEMENT (JPCP)

-

In this type of the pavement the steel reinforcement is not generally provided and having some transverse and longitudinal joints that are provided and some dowel and steel ties are used for transverse and longitudinal joints to control cracking.

This type of rigid pavement is generally provided for low traffic

-

PLAIN CONCRETE RIGID PAVEMENT

In this type of the rigid pavement the steel is not used just the concrete slab is provided with providing the joints of expansion and contraction. It is mostly used where traffic is very low.

Characteristics of an ideal rigid pavement

The requirements and facts for designing the good rigid pavement are following:

- Durable and low-maintenance cost

- Impervious enough for the protection of sub-grade soil.

- Skid resistance must be appreciable

- Smooth and the surface must be leveled

- Structurally strong enough to withstand the gradually increasing and impact type of loading

- Its is called as single layer pavement and its lifespan is up to 40 years if cared and maintained

- The surface may be provided with asphalt for topping to reduce the noise during the vehicle movements.

- As for the durability concerns this type of pavement is cheaper and its maintenance cost is low

- In case of the flexible pavement the loads are deflected from grain to grain but in case of rigid pavement the deflection is not so appreciable, but the load is distributed over a large are underneath the surface course.

- The slab action in the rigid pavement can distribute the heavy loads over the whole area and below the courses of pavement

Advantages & Disadvantages of Rigid Pavement

Pros

- Impervious and no deterioration under stagnant water.

- Low maintenance and operational cost.

- High strength and flexural rigidity.

- Good resistance to petroleum products

- They provide visibility at night hours and provided excellent riding surface under all conditions.

- The lifespan is more, and service life is about 30 years.

- The load carrying capacity is more and no corrugation and can be laid on the sub-grade.

Cons

- The surface of the pavement may become slippery with the life.

- High initial cost for the operation and construction.

- If any type of cracking occurs it is uncontrolled.

- Liable to cracks and warp due to weather conditions.

- They can cause reflection due to sunlight and become noisier with the time.

- They required skilled supervision and labor.

- They cannot be opened for the traffic shortly before curing for much busier roads too.

Components of the rigid pavement

There are following components of the rigid pavement as:

- Soil sub-grade, the lowest layer – Subgrade is the foundation for the pavement. It has be well-compacted with at least 95 to 98% of MDD (Maximum dry density). We mostly use vibratory steel drum roller to compact the subgrade. It has to be free from any undulation, loose patches or slush.

- Drainage layer – This is an optional layer. Engineers provide this layer where underground water-table is shallow and there’s a need to avoid water-percolation.

- Granular sub-base course – This is also an optional layer. It is provided above the subgrade if the bearing capacity of the subgrade is not sufficient.

- Base course

- High strength cement concrete pavement slab – This is the main concrete pavement. We lay it either manually or through a paver that works just like we see in asphalt pavements.

Factors affecting the design of rigid pavement

There are following factors that affect the rigid pavement greatly:

- Axle load (ESALS)

- Quality of drainage work and characteristics

- Type of soil in the sub-grade

- Types of the joints and their spacing greatly affect

Quality control of the rigid pavement

- The subgrade of the rigid pavement has to be well-compacted. You shall evaluate the compaction with the field density test (most suitable is water replacement method)

- Normally, experts recommend pavers but in case of reinforcement mesh you may not use paver and so the compaction of concrete is critical. You shall use internal or poker concrete vibrator of 50 or 80 mm diameter to properly compact the concrete.

- The slump of rigid pavement is kept low and so you shall not allow labor to manually add water in the concrete.

- The level or alignment shall be inspected prior to the approval of concrete pouring.

- You shall count and check the correct direction of dowels as well as tie bars. The sleeves of the dowels must be in coherence with the direction of the traffic. The tie-bar must be applied with anti-corrosive chemical to avoid water damage due to water-percolation.

- Proper grooves shall be made at the top surface if the wearing asphalt layer is not admissible.

- The concrete shall be tested at site for slump as well as compressive cylinders for 28 days strength. The engineer may demand to cast beam samples to check the flexural strength of the concrete.

- Curing shall be carried out properly by covering with hessian cloth or by ponding for at least 7 days.

- The ideal temperature for concrete pouring is 15 to 24 degrees Celsius.

- The concrete slab if rests directly on sub-base or subgrade must be poured on impregnable plastic sheet of 125 microns thick.

- Texturing shall be completed before the concrete reaches such a stage that the surface is likely to be torn or unduly roughened by the operation

- Saw cutting of joints of pavement slab as per stipulated dimensions should be done when concrete is neither too soft nor too hard. Sawing operations should start as early as Sawing operations should start as early as possible depending upon the season