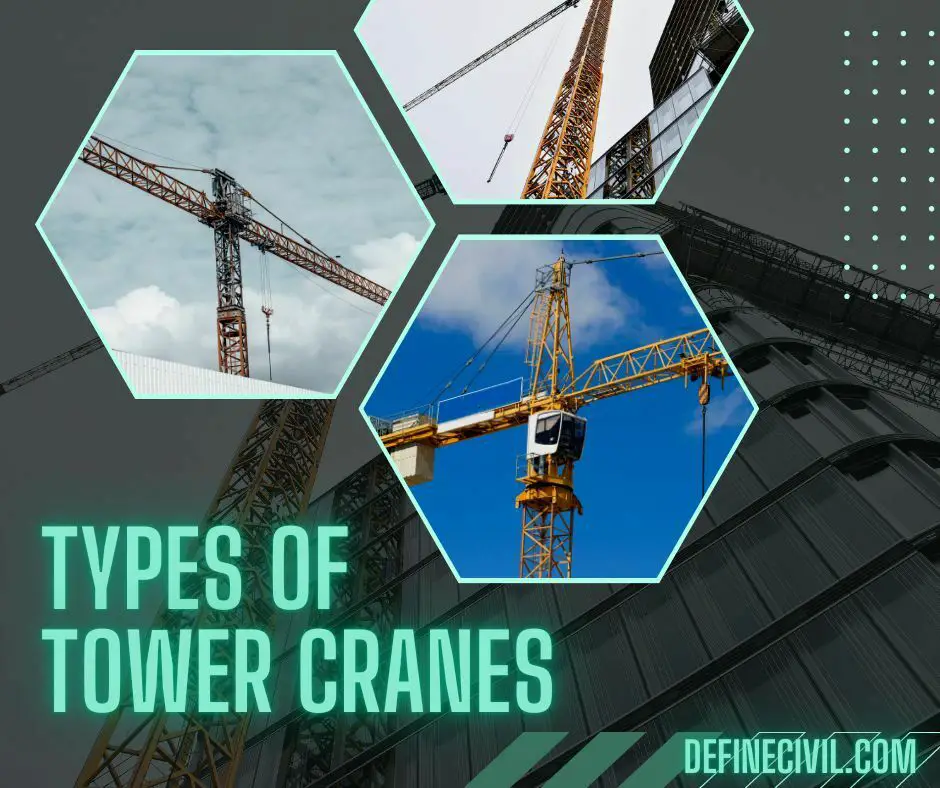

Have you ever seen that tall sky-touching tower taking bits and pieces of skyscraper materials during construction of a tall building? That’s a tower crane climbing tall doing all that lifting and moving works easier across the construction site.

During past few years, construction sector has reached the apex of technological advancements. With such cutting edge technologies, we’re seeing myriads of skyscrapers, bridges, towers, etc. around us. At the heart of this pinnacle, lies the heavy equipment and machinery like tower cranes.

Without these heavy machineries like tower cranes, it would have been impossible to build what mankind has achieved today. One of the most versatile construction machine is a ‘crane’. It has made it easier to lift and move materials and other building elements from place to place.

What is a tower crane and its structure?

Different types of cranes are being used in construction industry. Tower crane is one of those types used in the construction of skyscrapers.

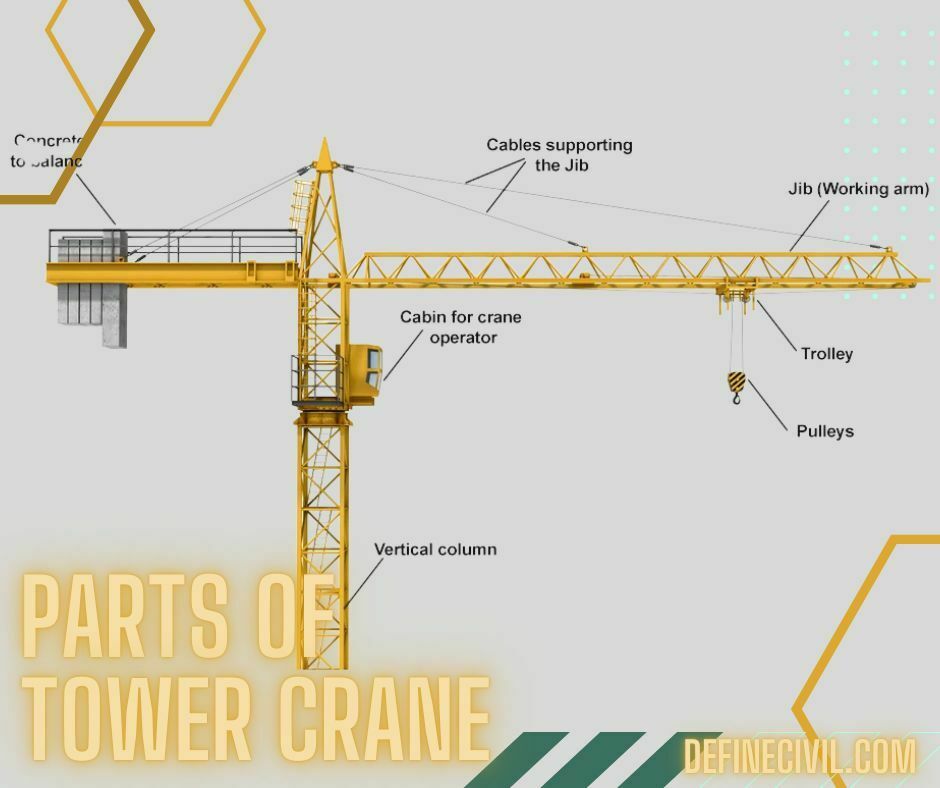

Let’s first understand the basic structure of a tower crane. It has a fixed vertical tower/mast that is topped by a rotating boom (long fixed or hydraulic arm that moves heavy objects) and equipped with a winch for hoisting and lowering loads. Here’re some common parts of a tower crane:

- Concrete counter weights

- cabin supporting cables

- Cabin for crane operator

- Vertical column or tower (hence named tower crane)

- Boom / Jib that’s a working arm

- Trolley

- Pulleys for lifting object

- Base foundation

These cranes are able to lift heavy loads at great heights, thus making the construction process at quicker and easier than typical mobile cranes.

By the way, I’ve explained in detail about various other types of cranes in my other article. Don’t forget to read that for other types. You can also watch the video here on YouTube.

In this article, we are going to discuss types of tower cranes and their properties.

Types of Tower Cranes

I’ve arrange different categories of tower cranes based on their general characteristics so it will be easier for you to digest and remember.

Static Tower Crane (Self-supporting)

These cranes are perfect for confined sites where maneuvering has to take place in a limited space. The crane tower foundation mast gets hocked with ground using reinforced concrete bases (foundation slab). However, this static type tower crane has no connection with the skyscraper of tower being built.

Sometimes it becomes necessary to use piles to give support to the tower because of poor ground conditions as a typical tower crane has got massive amount of load. The lifting capacity at minimum radius of trolley is around 2-2.5 tonnes and around 1 tonne at maximum radius at the end of boom. These cranes can maneuver loads at heights of 25 to 30 meters.

Supporting Tower Crane (Static)

This one is similar to self-supporting tower crane. Static tower crane is works best when higher lifts are to be achieved on a construction site. Support is provided by tying it to the face of the structure on which it is working.

Suitable distance is maintained between supports to ensure stability. Just like the case with climbing tower crane, the structure utilizing this crane has to be capable of supporting extra loads acting due to the weight of the crane.

Rail Mounted Tower Crane

Also goes by the name of travelling crane and is preferred on sites that cannot accommodate static cranes. Contractor builds a rail track that gest hold of the tower crane and allows it to travel from one place to another while carrying loads. The rail track is of sleepers and ballast and resembles the track we have for railways.

For such a type of tower crane, the load carrying capacity is around 1 ton at minimum radius and 4 tons at maximum radius at the end of boom. The load carrying capacity of this tower crane is around 1 ton at minimum radius and 4 tons at maximum radius i.e. at the end of boom.

For supporting and balancing the tower crane mast, you must use heavy concrete blocks on both sides. Turntables are also constructed to allow the crane to change direction. Generally, a slope of 0.5% works best to the track. Gradient higher than this value is usually not preferable for smooth running of mounted bogies.

Rail mounted tower crane

Climbing Tower Crane

The next tower crane on our list is climbing crane. It is ideal choice of tower crane for high rise construction. The purpose they serve is same as that of any other tower crane. However, their installation and maneuvering is different from that of other cranes. As the construction progresses, the crane gets up and has no connection to the ground anymore. So, it climbs up the concrete walls or floors of the structure as the construction advances.

The mast gets embedded within the structure and lifted as the structure itself becomes higher during construction. You need to consider all aspects of construction in view before taking any decision of choosing climbing tower crane here’re some important considerations:

- The structure has to be capable of supporting the loads from crane

- The frames should be structurally suitable vis-a-vis the structure under construction.

Hammerhead Tower Crane

These cranes are immensely popular on construction sites. These are used to lift heaviest loads accurately and safely. In a hammerhead crane, the boom can rotate in a complete circle (360°) in a horizontal plane while being fixed on the mast.

The shape of this crane resembles the L shape. Furthermore, these cranes are capable of racking i.e. the trolley can move the load horizontally along the boom without changing its level.

Luffing Tower Crane (Latticed Jib)

Luffing means raising or lowering the jib/boom of the crane to carry loads. The jib of such crane is latticed which allows higher mobility. It can lift heavier loads than hammerhead cranes. Moreover, these cranes are preferable in confined areas because of their reduced slewing radius.

Note: Slewing is the angular rotation of crane boom in a horizontal plane.

In addition to that, if a number of cranes are to work together, this crane is preferred because of less slewing radius.

Latticed boom

Tower Crane with Articulating Boom

This crane has distinct features with regard to the movement of boom. In this crane, the boom not only moves in horizontal position but it can move at different angles.

This feature allows versatility in lifting loads especially in tower construction. It is particularly well-suited for communication towers.

Tower Crane with Folding Boom

This type is specifically suited for congested areas. Its boom can fold within its length and maneuvering can take place within limited space.

Also, if there are obstacles on construction site which cannot be removed at the time of work, this crane is usually preferred. This is because the boom can work its way around the obstruction at certain angles. The folding angles are usually between 20-70°.