You have to select from different shape bricks while constructing any building. The selection of the type of bricks is a tricky step so we are here to help you.

Beside many other benefits that are derived from the uses of bricks, one of the primary reasons for the popularity of bricks among architects, designers and builders is its ability to adapt different shape bricks.

The bricks are used in variety of traditional and modern situations from walls to columns, treads, copings, sills and arches. The shape bricks we are about to discuss are actually common throughout the world and you don’t have to order specially for them.

However, in comparison to ordinary bricks they are manufactured in less quantity.

Although the bricks can be made in any size and shape depending on the needs of the project but there are some standard different shape bricks must to know for a construction manager or a civil engineer.

So in this post our main focus would be to identify, explain the use along with pros and cons of different shape bricks.

It is important to note here that the standard mostly followed for the shape / standard dimensions of the facing brick is stated in ASTM C-216. So for dimensional tolerance of different shape bricks you can consult this standard.

Here is a list of different shape bricks commonly used in a building project and all have a special purpose and location where they are mostly used.

List of Different Shape Bricks

-

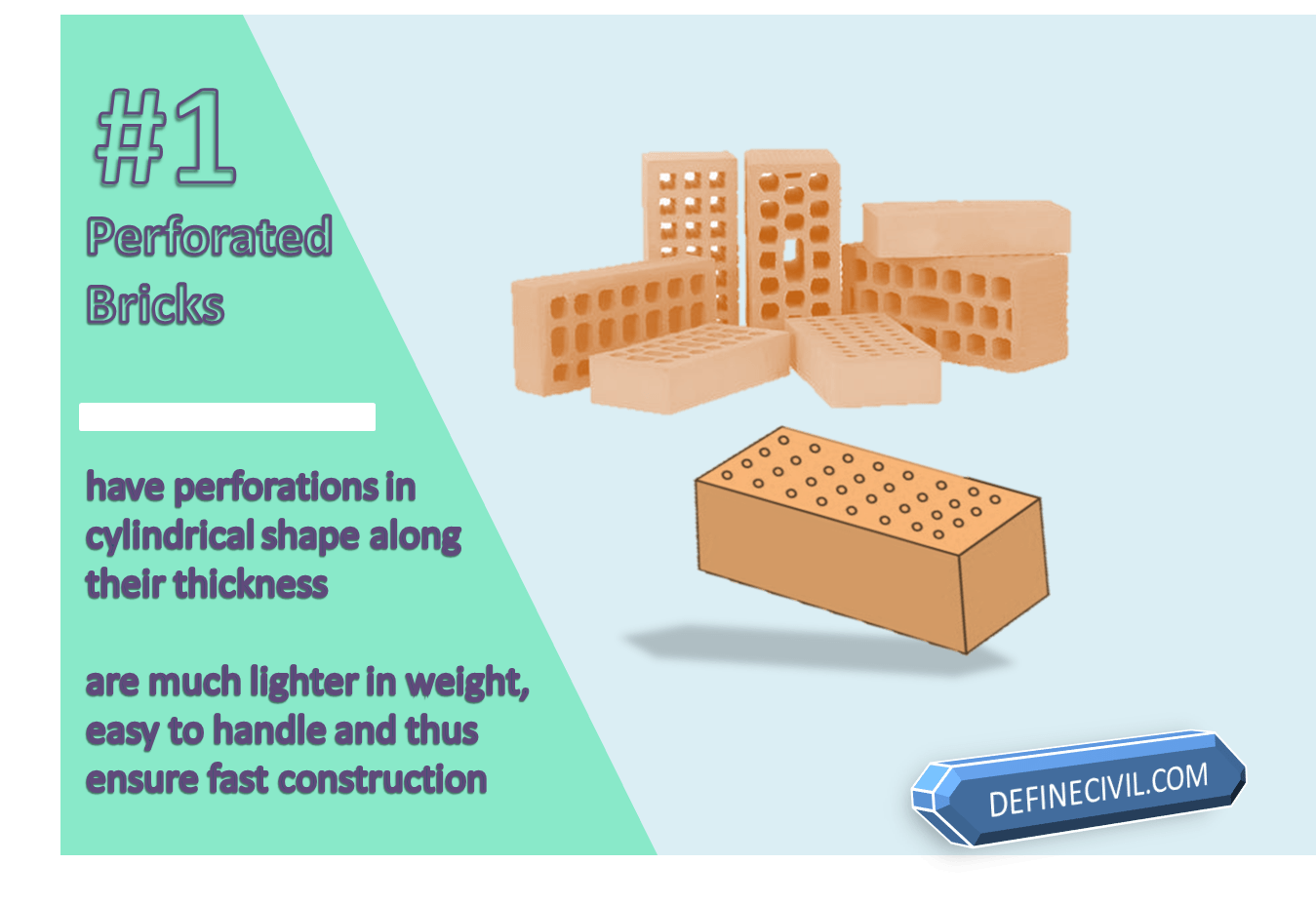

Perforated Bricks

Perforated bricks must not be confused with hollow bricks in the sense that perforated bricks have small diameter large number of holes or cavities. Perforated bricks give more compressive strength than the hollow bricks discussed below.

The perforated have perforations in cylindrical shape along their thickness. At the time of casting the bricks, iron tablets are pushed into the matrix of a brick to achieve a perforated material.

- The purpose to have these holes is to use the insulation properties.

- These bricks are much lighter in weight, easy to handle and thus ensure fast construction

- They can dry and burn quickly and easily.

- However, these bricks are never recommended for the hydraulic structure.

- Reduced usage of clay material.

The general dimensions of perforated bricks are 19×09×9 cm and 29×9×9 cm. Perforation area should not exceed 30 to 45% of the area of face.

-

Ordinary Bricks

Ordinary Bricks are solid rectangular blocks of standard shape and size with sharp edges and corners. These bricks are used as header or stretcher in a course and in ordinary projects they are only used for construction walls of 9 inches or 4.5 inches.

The nominal dimensions of the ordinary bricks are 225×112.5×75 mm (9”x4.5”x3”) but the architectural size or working dimensions or actual dimensions are 215 x 102.5 x 65 mm (8.5”x4”x2.5”). The ordinary bricks have different classes of quality and can be used both as load-bearing and non-load bearing walls.

-

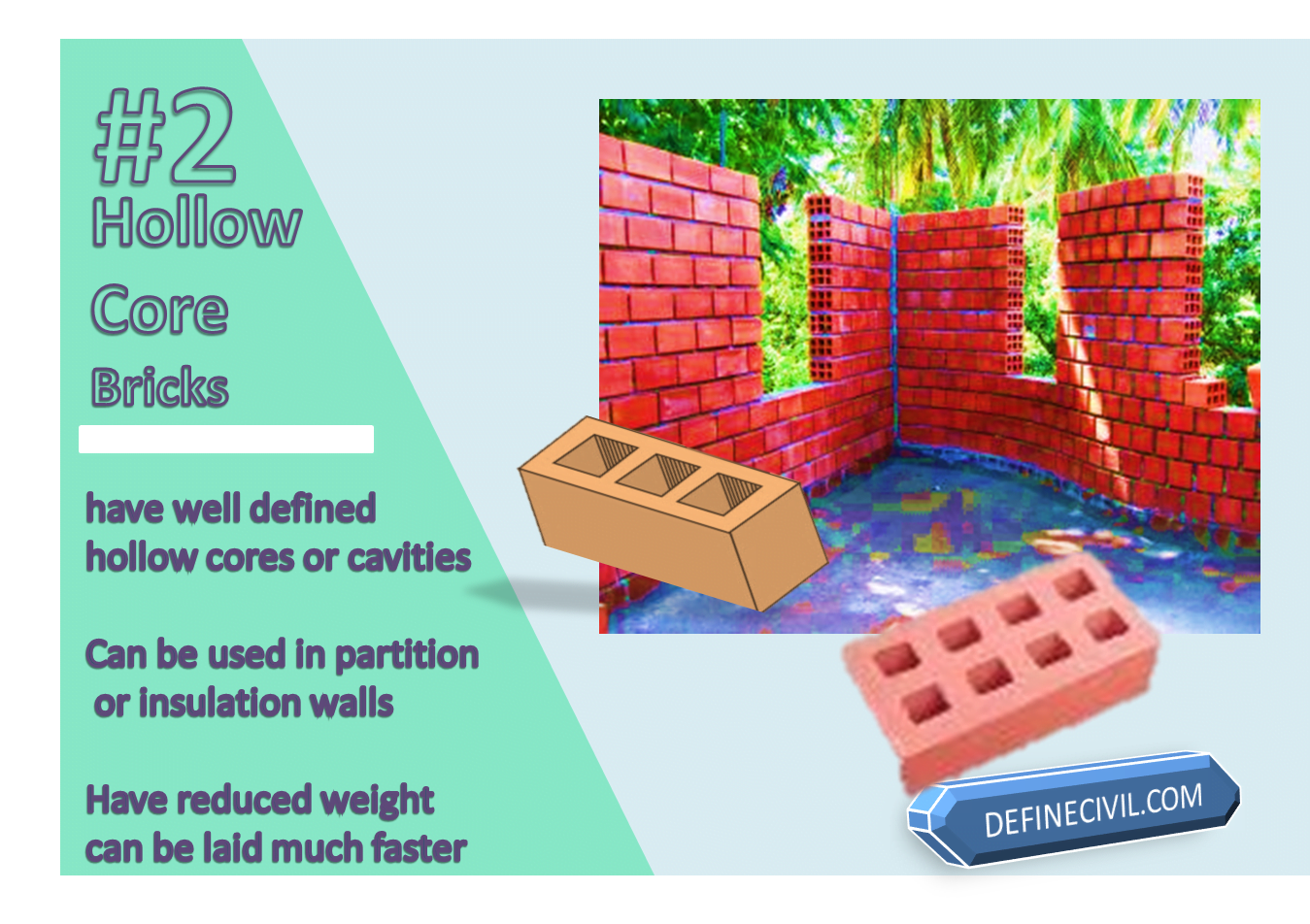

Hollow Bricks

As the name suggest for the shape brick, the body of the brick have well defined hollow cores or cavities of standard shape and dimensions. These bricks are also termed as cavity brick, insulation brick or cellular brick.

Hollow bricks are perfect for insulation cavity walling as due to hollow cores they reduce the transmission of heat, sound as well as dampness.

As compared with both hollow concrete blocks as well as solid bricks, the hollow core bricks weigh way less i.e. according to one estimation it weighs about one third of the solid brick. So due to reduce weight it is much easier to handle and thus they are proven to increase the pace of work rendering masonry work in less time.

According to some companies that are manufacturing this shape bricks; they can be used in both load bearing and non-load bearing cases; but our recommendation is that the compressive strength of the brick must satisfy the requirement of standard before using them in load bearing walls.

So the advantages of hollow core bricks are as follows :-

- Can be used in partition walls

- Have reduced weight than ordinary bricks

- They can be laid much fast than the ordinary bricks

- Are best suited for insulation walls

-

Bullnose Bricks

Bull nose brick as the name suggest is a special moulded brick having rounded angle along one corner edge either vertical or horizontal direction thus termed as bullnose.

This shape of brick is used for a rounded quoin or in copings or in such positions where rounded corners are preferred to sharp arises. The connection formed when a wall finishes a turn is called quoin.

A brick moulded with a rounded angle is known as a Bullnose. These types of bricks are used for a rounded quoin (round corner). An external corner of a wall is known as quoin. The centre of the curved position is situated on the long centre-line of brick.

if two sides of the brick is rounded then it is known as double bullnose bricks.

-

Cownose Bricks

Cownose brick is similar to bullnose brick with slight difference that in cow nose brick both the corners of the brick are moulded with rounded corners. It is also termed as double bullnose brick. The bullnose bricks are used at the edges where angular curved corners are recommended.

-

Channel Bricks or Gutter Bricks

These types of bricks are high strength glazed bricks used at the edges of a paved way or a hallway for the drainage purpose thus termed as drain bricks or gutter bricks. These bricks are moulded in the shape of channel like a drain.

-

Coping Bricks

These bricks have width equal to or greater than the width of wall to cope with the drainage of rain water. In simple words this brick is used at the top of parapet wall to provide coping to the wall. The shape of the brick can be chamfered, half rounded or saddle back as shown in the picture. Sometimes they are just used by the architect for the aesthetic purpose i.e. to match with the theme of the building.

-

Curved Sector Bricks

These types of bricks are in the form of curved sector. These bricks are used for construction of circular brick masonry pillars, chimneys etc.

Some other shapes of bricks are:-

-

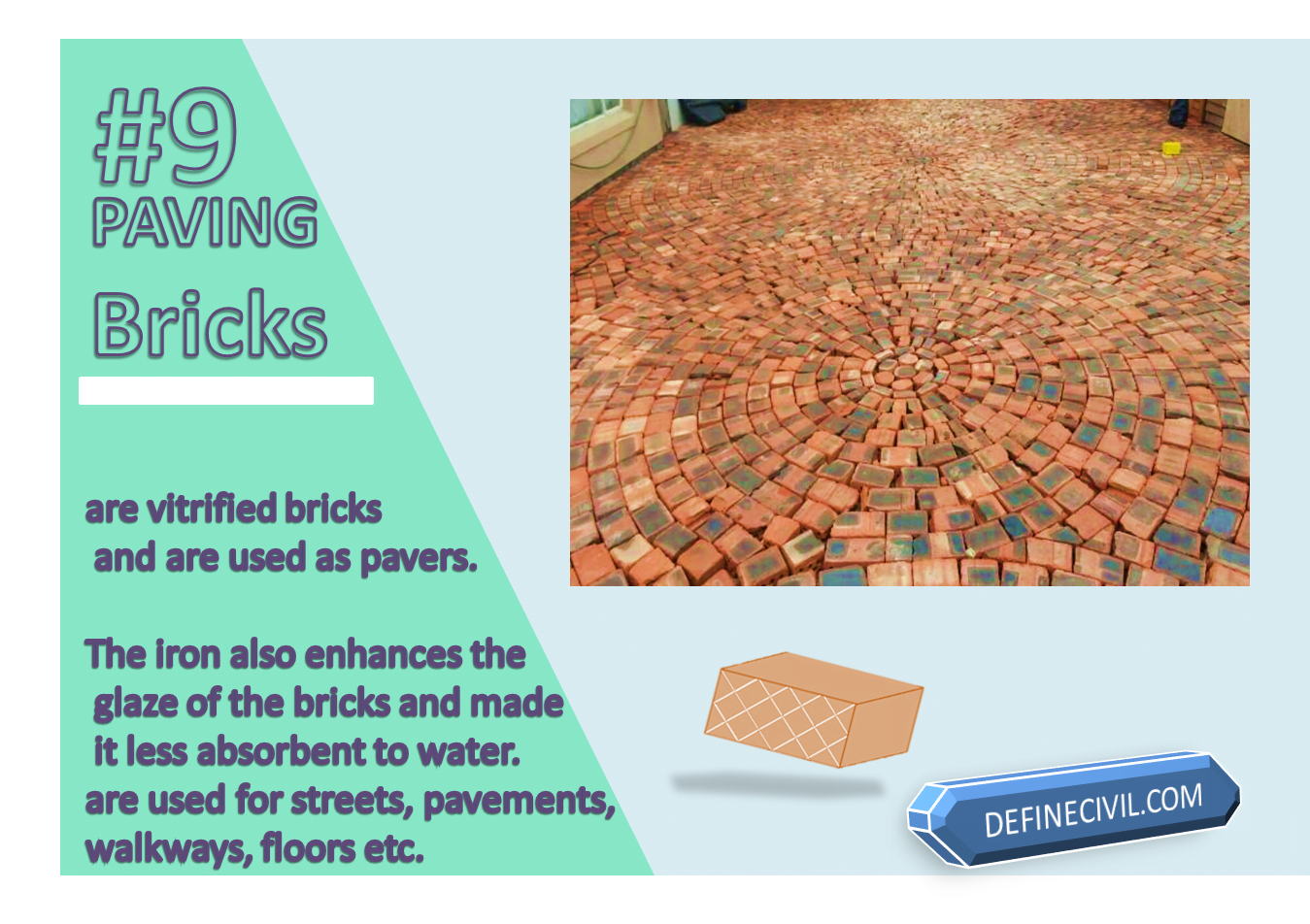

Paving Bricks

These are vitrified bricks and are used as pavers. By the word vitrified it means that during mechanical manufacturing or these bricks iron oxide is added to it in a process called vitrification at low temperature. The introduction of iron oxide makes it resistant to abrasion and enhances the compressive strength of the brick.

The iron also enhances the glaze of the bricks and made it less absorbent to water. According to IS 3583-1975 the paving bricks must have compressive strength of above 400 kg/cm2 while the dimensions must be between 19.5 x 9.5 x 9 or 19.5 x 9.5 x 4.

The surface of the paving bricks can be chequrered by rough tool to enhance friction and avoid being slippery.

Uses: Paving vitrified bricks are used for streets, pavements, walkways, floors etc.

-

Dogleg / Angle Bricks

The dog leg brick is a special shaped brick that is used to turn brickwork through an angle. It does not have a rectangular shape, the edges along the narrowest side forms an obtuse angle. These bricks are also termed as angle cut bricks.

The use of dogleg brick enables to avoid the use of cut bricks and a mortar joint where the face of the wall changes direction.

-

Queen Closer

Queen closer is actually not a manufactured shape brick but is actually made by cuting along its length into two equal halves called queen closer. Queen closer is also termed as bonding bricks.

Queen closer is used to close up the bond at the end of the course. It prevents the joints of successive courses (higher or lower) to come in a vertical line.

-

King Closer

Like queen closer the purpose of king closer is the same, it is cut from the ordinary size bricks. The king closer is made by cutting the brick one half of its one dimension to the other half of its second dimension thus a triangular piece is removed which helps in making the corner course.

-

Purpose Made Bricks

As the name suggests, the purpose made bricks are those that are moulded in special shapes to serve a special purpose. Although you can obtain bricks for those purpose from ordinary size brick by cutting or toweling but in that case it takes time and the uniformity is also not achieved.

So in such cases, these purpose made bricks were manufactured by different companies to ensure quicker construction.

The following are the various types / shapes of purpose made bricks :-

- Ornamental bricks to satisfy certain shape like cornices, corbels, pergolas etc.

- Splay or cant bricks: these are used at the jambs of the door or windows.

- Arch bricks: these are used in arches where it is required to keep the thickness of joint mortar uniform.

Final notes….??

So there are different shape bricks being manufactured for special purpose and locations. Knowing all of these would help you in understanding when to use which type of brick. I have tried to cover all of the types but if you think I have missed something do let me know by commenting below.