Concrete is a brittle material but do you know it still has elasticity and hence modulus of elasticity is an important parameter civil engineers used during design of structures.

What you think, is there a relation between strength and modulus of elasticity of concrete?

Well, concrete does has enormous flexural as well as compressive strength. But, it’s a well-established fact that there’s a direct relationship between strength and brittleness.

Concrete is a brittle material

We call concrete brittle because it fractures with little elastic deformation when subjected to stress. That’s why we use steel reinforcement to enhance flexural strength and elasticity. With such, the concrete shows much signs of warning before ultimate failure.

Simple concrete absorb little energy prior to fracture, regardless of the strength. Similarly if you’ve been around a concrete laboratory, you might have seen testing of concrete cylinders. When these cylinders are crushed in UTM it breaks off with sharp snapping sound.

Elasticity of Concrete

To understand elasticity and developing modulus of elasticity of concrete, you need to have a good understanding of stress-strain curve. A fully elastic material has a linear relationship between stress and strain. That’s what has been well-established by Hook’s law.

See Also: Workability of Concrete – Definition – Factors affecting

Although in theory of reinforced concrete we assume concrete as elastic, isotropic, and homogeneous material. But in reality the assumptions are not strictly true. The concrete is not a perfectly elastic material. The stress-strain behavior of concrete is bit complex. It depends on the magnitude of load, rate of load application, and time of loading.

Modulus of elasticity of concrete indicates stiffness of the concrete that has an impact on the strength. In mathematical meanings, modulus of elasticity is a ratio between applied stress and associated strain below the proportional limit of elasticity of material. Modulus of Elasticity is expressed as “Ec”.

It is mathematically given as:

Modulus of Elasticity of concrete = Unit stress / Unit strain

Concrete with different mix designs have different value of modulus of elasticity of concrete but all do shows relation with the compressive strength. The type of aggregate and their gradation also impacts the elasticity of concrete. Typical range for modulus is about 30 to 50 GPa. (Giga Pascal = that’s because strain has no unit so Ec takes unit of stress).

See Also: Weight of concrete – Density-Concrete Slab-Driveways

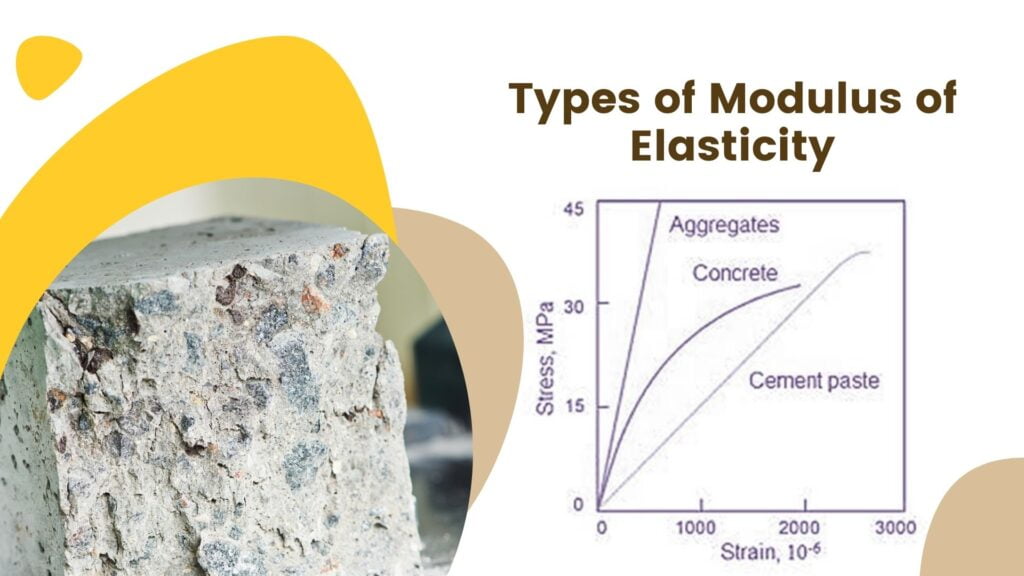

Plot of Stress – Strain Curve

Different materials like steel, cement, aggregate and concrete has a different shape of plot between stress and strain. Concrete on stress-strain curve depicts a non-linear behavior.

If you see these curves J – K and L. the J is the curve for aggregate – being the stiffest. K is for the concrete while L curve is for the cement.

Now here to get the modulus of elasticity, just evaluate the slope of the curves. The curve with stiff slope will have the largest value of modulus of elasticity.

See Also: Curing of Concrete -Methods -Temperature – Stages – Importance

Importance of elasticity of concrete

While you’re designing concrete structures, it is vital to fully understand theory of elasticity. We need concrete structure like a beam that not only takes applied loading without failure but also doesn’t deform much during serviceability. We can’t use a bridge that deflects too much under loading although there’s no chance of failure, right? Hence there’re two things to consider during design of concrete structures:

- Strength adequacy

- Serviceability requirement (deflection and deformation)

The rigidity of a structure or a material is defined by two parameters:

- Moment of Inertia

- Modulus of Elasticity

Moment of Inertia (I) is purely a geometric property depend entirely on the shape of concrete structure cross-section. However, the modulus of elasticity depends entirely on the composition and constituents of concrete.

| Sr. No. | Average Compressive Strength of Concrete cube Mpa | Modulus of Elasticity GPa |

| 1. | 21 | 21.4 |

| 2. | 28 | 28.5 |

| 3. | 35 | 32.1 |

| 4. | 42 | 35.3 |

| 5. | 56 | 42.9 |

| 6. | 79 | 65.4 |

See Also: What is Prestressed Concrete? – Pre tension- Post Tension-Applications

Factors effecting modulus of elasticity of concrete

As I’ve already explained that modulus of elasticity depends enormously on the concrete compressive strength. So any factor or a thing that would impact the compressive strength would eventually impact the modulus of elasticity of concrete. We can write those factors as:

- Mix design (obviously the biggest factor is mix design)

- Coarse aggregate properties (aggregate makes concrete stiff)

- Loading rate

- Curing conditions

- Mineral Admixtures

- Chemical Admixtures

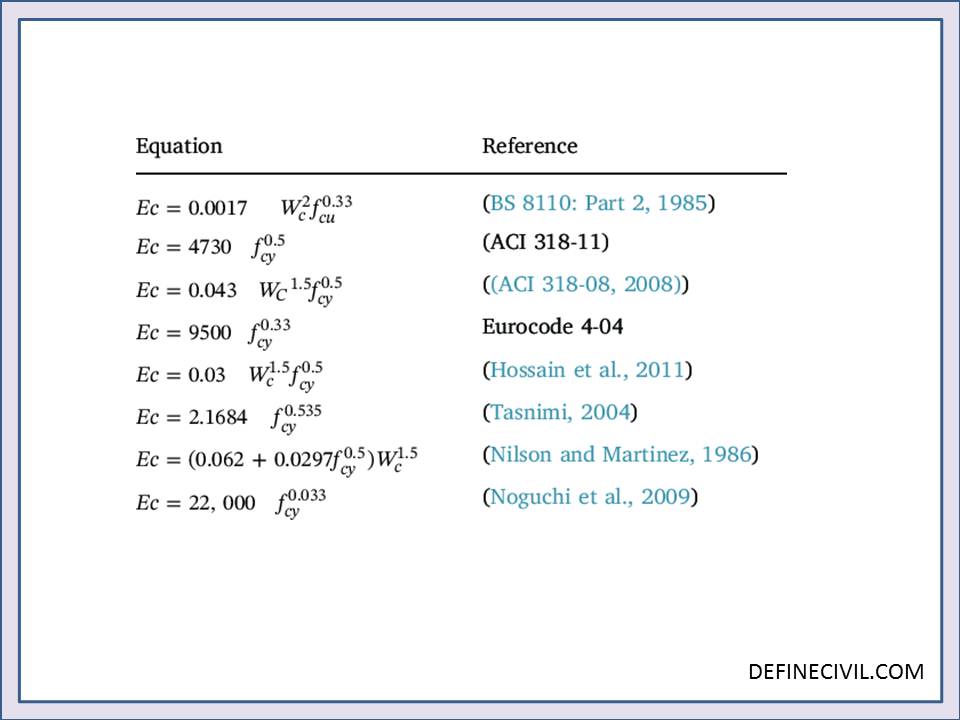

Recommendation as per ACI 318-04

ACI 318-08 gives elastic elastic modulus as

Ec = 0.043(wc^1.5)√(f’c), MPa,

Where f’c is specified compressive strength of concrete

Wc is unit weight of concrete

For normal weight concrete by entering the density of concrete, we modify the above equation as:

Ec = 4700√(f’c), Mpa

Indian Standard

According to IS:456 the modulus of concrete is given as

Ec = 5000√(fck), MPa ,

where fck is the characteristic compressive strength of concrete.

Canadian Standard

As per the Canadian Standard Association (CSA), we can define modulus of elasticity as:

Ec = 4500√ fc’ (in Mpa)

for high strength concrete:

Ec = (3300√f’c + 6900)(W/2300)1.5 (in Mpa)

Eurocode

For Eurocode you can define the modulus of elasticity with below equation:

Ecm = 22 [(fcm)/10]0.3

where

Ecm = modulus of elasticity

fcm = mean compressive strength of concrete at 28 days according to Table 3.1 BS EN 1992-1-1:2004

British Standard

BS 8110 Part II of 1984 publications defines modulus of elasticity of concrete on the basic of 28 days of concrete age as

Ec,28 = K0 + 0.2 fcu,28

where K0 is 20 kN per square millimeter for normal weight concrete

and Fcu28 is concrete compressive strength at 28 days.

See Also: Properties of Hardened Concrete

Different Types of Modulus of Elasticity of Concrete

We can classify the modulus of elasticity in two groups specifically for concrete:

- Static Elastic Modulus

- Dynamic Modulus

Static Elastic Modulus

Modulus of elasticity determined under uniaxial tension or compression helps us in defining static elastic modulus. While we test the specimen under uniaxial tension or compression, the following curve is obtained:

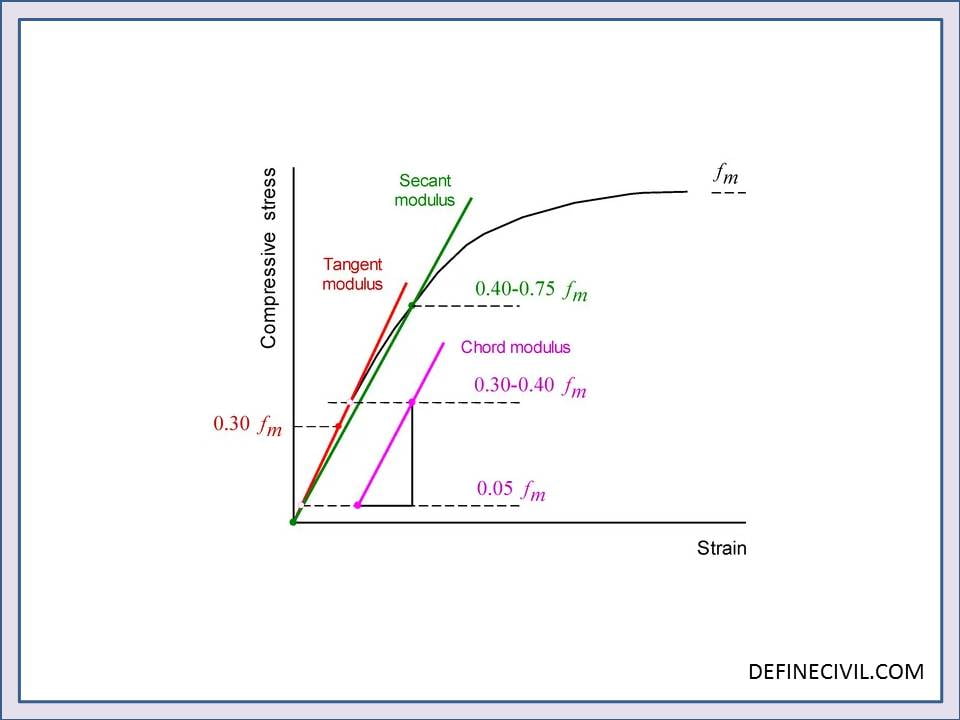

The concrete, being imperfect elastic material, gives a curved line in stress-strain relationship. We can use three methods to determine the modulus of elasticity:

- Initial tangent modulus

- Tangent modulus

- Secant Modulus

At the initial phase i.e. when the stress-strain curve is linear, a tangent is drawn meeting the origin. The slope of this tangent is termed as initial tangent modulus. But engineers won’t use this modulus in design as it is of no practical importance. It is only applicable at low stress value which does not depict the true behavior of concrete.

You can obtain tangent modulus on the stress-strain curve at any point. That modulus is termed as tangent modulus. Obtaining tangent modulus is difficult and is not accurate.

The other type is secant modulus or chord modulus. It is one of the most common types of modulus of elasticity preferred for concrete. To determine, a specific point is selected on the curve and a chord is drawn with the initial linear portion. The slope of this curve is known as the secant modulus. The value of this modulus will be different at different stress levels and so the stress has to be mentioned while writing secant modulus of concrete.

See Also: Advantages of Air-Entrained Concrete

Dynamic Modulus

Concrete during service life is not only under pure compressive or tensile stress. Instead, it is in amalgam of these stresses and creep. So, the modulus of elasticity that is determined during actual loading of concrete is termed as dynamic modulus of elasticity. This modulus is determine by subjecting the specimen to longitudinal vibration at their natural frequency that is why this is known as dynamic modulus.