Prestressed concrete is the most extensively used form of structural concrete beside conventional reinforced concrete. In process of prestressing, we enhance the tensile strength of the structural element like a slab or beam. We introduce tensions steel wires or cables that induce compression in the concrete. We do this process before applying the external load on the concrete.

As a result, the structural element stays in a negative tensile stress that neutralizes when an external load is applied.

But that’s not a simple process. That’s why our today’s article is about what is prestressed concrete and everything you need to know about it.

What is prestressed Concrete?

The steel strands and wires are largely responsible for providing the required load-carrying capacity of reinforced concrete structures. In prestressed concrete, tendons are first stretched over pre-tensioning devices such as anchorages or pulleys either at one end or both ends of the structure using hangers or turnbuckles before pouring the concrete.

Definition

As soon as concreting work gets completed, either immediately or after some time depending upon the curing period of concrete, steel tendons are kept under compression till complete finishing operations – including painting, application of waterproofing, and laying of floorings – are completed.

What is a tendon?

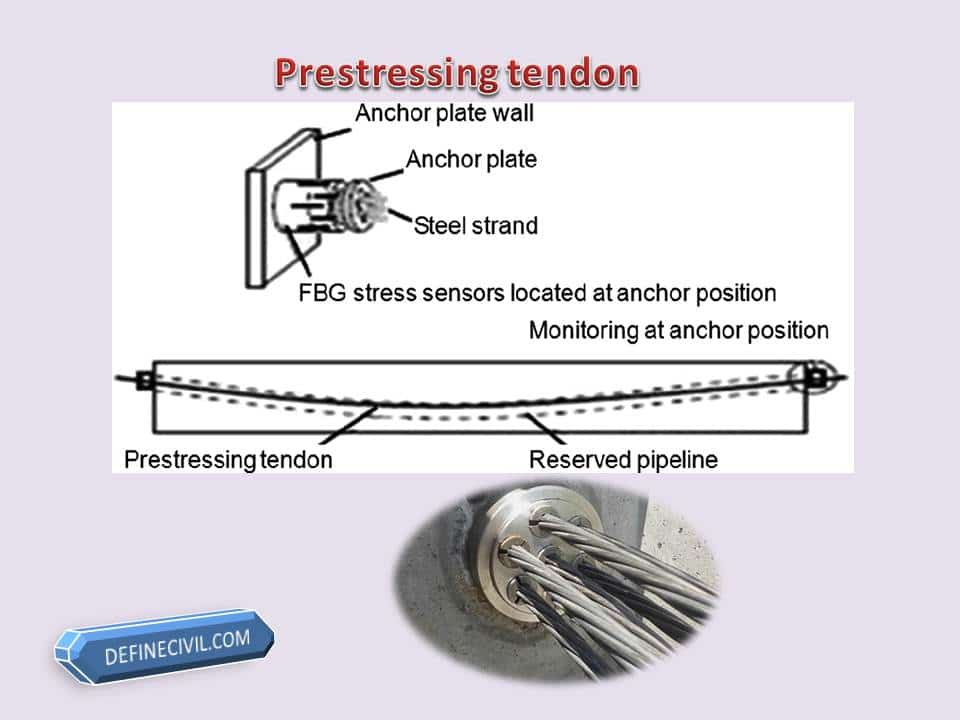

A tendon is a core member and a basic element in prestressed concrete that plays an important role in post tensioning. A typical tendon is comprised of steel strands or wires. It can be of single wire or multiple wires woven in a spiral. In post tensioning, these tendons are passed through ducts or sheathing embedded in the concrete member.

The tendons are high tensile strength steel strands that have yield strength of about 243,000 psi in comparison to steel rebar that only has about 60,000 psi.

Each end of the tendons has anchors that have clips that secures the tendon and transmits compression force to the structure. Sometimes the length of tendons is more and thus intermediary anchors are used along their length to transmit stresses at joints. A typical steel strand (which is the basic element of tendon) is in size of 0.50 and 0.60 inch.

The tendons are sometimes applied with grease and then the sheathing is not backfilled with grout. In a typical application, we close the tendon ducts or sheathing by non-shrink backfill grout. Tendons that doesn’t make bond with concrete are called unbounded tendons.

How prestressing works?

So, to understand the basic working of prestressing and why we require it for beams or slabs, you need to revise the basics of concrete.

You know by definition that we introduce compression in the member. Compression is the force that crushes the element or structure member while tension is the force that pulls it apart or away.

As concrete is strong in compression and weak in tension, we want to reduce the tensile stresses in concrete during service life. On the other hand, steel is strong in tension and weak in compression.

Thus, in ideal situation, if a structure is in a state where concrete is in compression and steel is in tension, before applying service load, we are actually enhancing the load carrying capacity of the structure.

Let’s take an example of a typical simply supported beam. In such a beam we provide rebars at the bottom section of the beam. That’s because the bottom part is the tension zone and concrete would fail in tension being weak.

Now if you need to design structure where loading is too heavy or you need a thin section, what’d you do? The only solution is to enhance the amount of reinforcement. But that is not a feasible and economical solution.

That’s where we need the concept of pre-stressed concrete.

If you can apply a permanent force in a structure that introduces negative tension or reverse tension than the service loading, you can enhance the load carrying capacity without increasing the reinforcement or increasing the cross-section of the beam.

Also Read: Post Tension Slabs – Detail – Components – Advantages – Cost – Applications

In the same simply supported beam, if you apply pre-tension you’re compressing the beam such that it has tensile stress at the top and compressive stress at the bottom fiber of the middle portion.

Now when the loading is applied in vertical downward direction, the compression would counteract the tension force under service loading.

Difference between pre tensioned and Post tensioned concrete

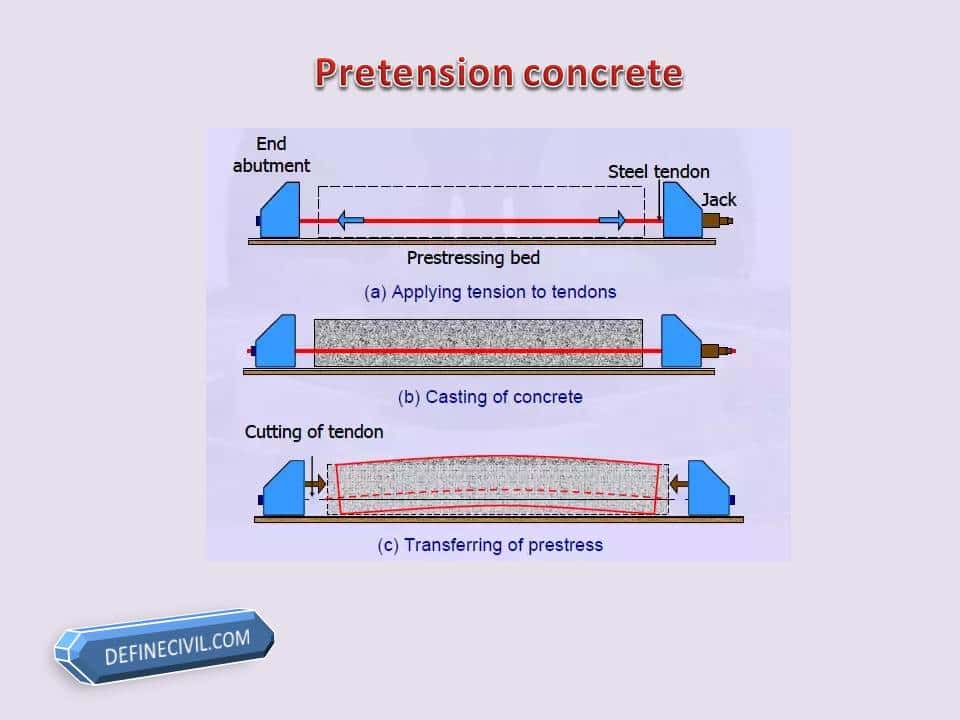

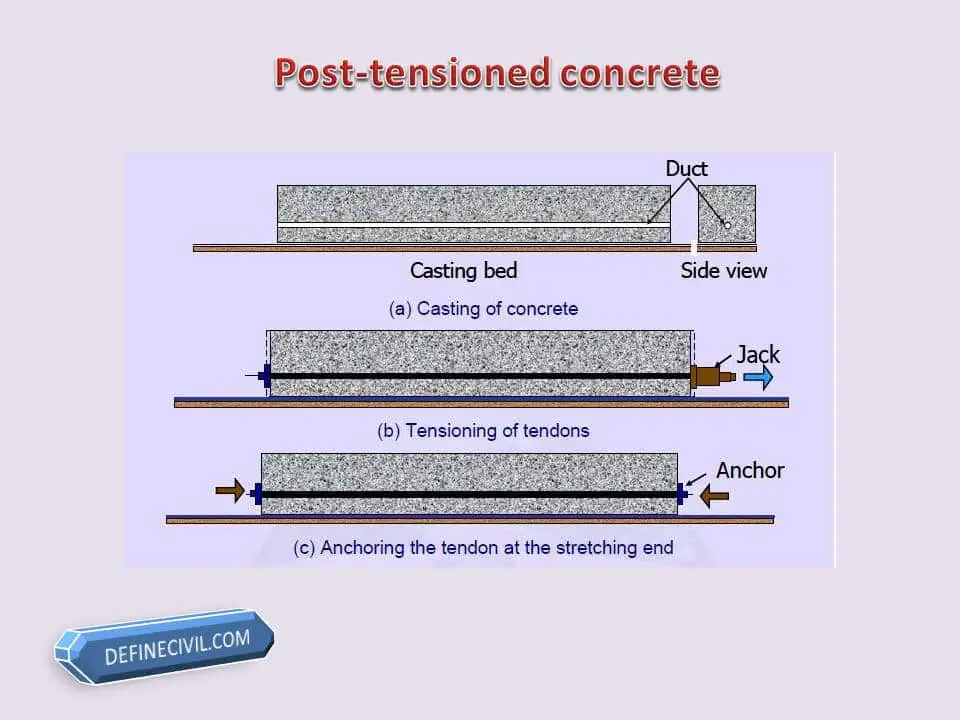

Pre-tensioning is a type of prestressing when the compression force is induced before pouring concrete while Post-tensioning is a type of prestressing when the compression force is induced after pouring and curing of concrete member.

In pre-tensioning, steel wires or cables are fixed in the structural element and is stretched and anchored at the ends before the concrete is cast. After pouring the concrete, the temporarily anchored tendons are released that introduces the compression forces at the end. The prestressing force is transferred to the concrete of the structure by the bond along the length. Pre-tensioning is not much common as post-tensioning. However, it still finds application in precasting plants for building industry. Pre tensioning is preferred when you need to produce mass products like electric poles, precast beams, slabs, or cellular modules of longspan bridges.

In post-tensioning, we embed a duct or sheath in the concrete for the strands. After setting and curing of the concrete, we reeve the tendons through the duct and provide anchorages at the ends. These strands or tendons are then stressed one by one at one or both ends of anchorages.

Which is better – pretensioning or post tensioning?

Now you have the basic concept and difference between pre-tensioning and post-tensioning, let’s now see which approach is better.

Well, this depends entirely on your project loading requirements and size of the structural elements. Both the methods have their own pros and cons. Pre-tensioning is durable and long-lasting as the compressive force is applied across the entire length by bonding. There’s no influence of the end-anchorages. Whereas, in post-tensioning, you need to have high-quality anchorages because all the effort relies on the durability and life of two anchorages.

But at the same time, the loss of strength in pre-tensioning is more i.e. about 17% as compared with post-tensioning where it is only about 15%. In pre-tensioning there’s a significant need to protect prestressing elements from rusting or corrosion but that is not the case with post-tensioning members.

Also Read: Concrete Retarders – Disadvantages – Types – Uses – Price

Anyhow, pre tensioning is cheaper as there’s no sheathing or costly anchorages are required.

However, in a typical project pre-tensioning is a preferred method when the structural member is small and you can easily transport it. You can prefer pre-tensioning for precast construction works as it can be easily done in factories. While the post-tensioning is a preferred method of prestressing when the element is heavy and you can’t transport it easily. You might have seen post-tensioning in long-span bridges and girders because post-tensioning can be done at site.

How is prestresssed Concrete Made?

Prestressed concrete is a high-strength concrete in comparison to normal reinforced concrete. Generally we need a minimum 28 days cylindrical compressive strength of 5000 psi. That’s because we want the concrete to bear extra compression that can otherwise crack due to prolonged induced stress. IS recommend a minimum mix of M40 for pretensioned concrete and M30 for post tensioned concrete.

The rebar we use is a typical grade 60 rebar with 60,000 psi yield strength but it typically is reduced in a pre-stressed member. Along with this, we need tendons that are high tensile wire or strands that are stretched with prestressing.

Now the construction procedure depends on the type of prestressing. The procedure is already explained in above pretension and post-tensioning methods.

Difference between RCC and Prestressed Concrete

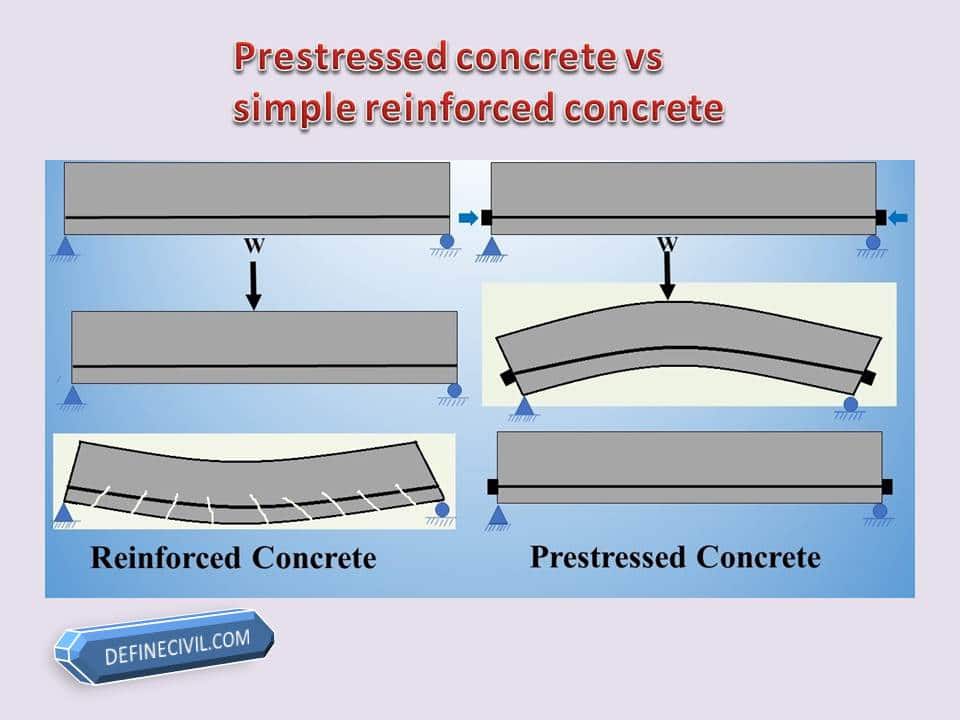

Conventional reinforced concrete relies on reinforcement bars to cater for the tensile stresses produced as a result of external loading. On the other hand, prestressed concrete uses induced compressive forces to neutralize and counteract the imposed tensile stresses.

Typical reinforced concrete members are bigger in cross-section and are heavier. This limits the opportunity to have long-span beams and slabs. Prestressed concrete makes it possible to have light weight structural elements that can have longer spans without the need of columns or struts.

Applications of Prestressed Concrete

Prestressed concrete members are used extensively for a variety of load-bearing structures. These include:

- Bridge Structures

- Flyovers

- High rise buildings

- Commercial complexes

- Industrial structures

- Mining & mineral processing plants

- Sports complexes

- Suspended Ceilings

- Acoustics ceiling panels

- Electrified rail tracks

- Heavy traffic bridges

- Railway over bridges (ROBs)

Wrapping Up

Prestressed concrete has made it possible to build tall skyscrapers & other such structures as they are more economical than steel construction and have relatively better seismic resistance. The systems used for pre-tensioning in these applications are generally post-tensioned (PT) and precast prestressed concrete. With the many advantages it has to offer, prestressed concrete is definitely worth the investment.