It is one of the most widely used soil compactors used by contractors and builders worldwide. The sheepsfoot roller is a piece of heavy self-propelled equipment usually mowed and runs in a static position. Depending on the character of the soils, this sort of roller is available in several sizes.

It is one of the types of soil compactors with other types like pneumatic tyred rollers (PTR) and vibratory steel drum rollers. All these types have different behaviors in compaction action and hence it is crucial to select the right type for your use.

What is a sheepsfoot roller?

Famously known for compacting clayey or silty soils in road construction, sheepsfoot rollers are best. They compact the soil with kneading action that enables it to compact wet clay or fine-grained soils at greater depth. Civil Engineers also refer sheeps foot roller as padfoot or tamping rollers.

Do you know why we call them as “sheeps foot roller”:

Well, instead of having a smooth drum rim like steel drum roller, they have a rolling surface with projecting spikes. This gives them a rough shape of what we see in foot of a sheep.

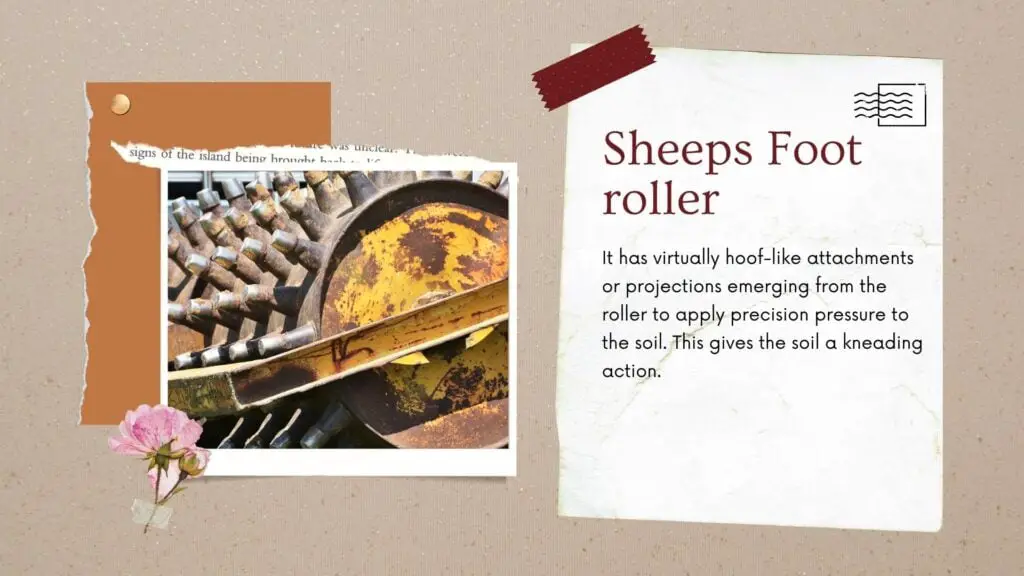

Design of a sheepsfoot roller

It has virtually hoof-like attachments or projections emerging from the roller to apply precision pressure to the soil. This gives the soil a kneading action. The drum’s protruding studs resemble a sheep’s foot. Depending on the manufacturer’s standards, the teeth size varies slightly from one sheep’s foot roller to the next. It works well for the compaction of plastic soils like silt or clay.

Compaction of clayey or silty soils

The compaction of clayey soils is a bit different as compared with sandy or gravely soils. The later type of soil quickly fills gap when vibrated or pushed. In contrast, a clayey soil is difficult to compact.

Clayey soils needs an optimum level of water-content that we refer to as “optimum moisture content”. The voids in clayey soils when are fully saturated with water allows the clay particles to move past each other. So, the only way to compact such soils is by squeezing out water and air through kneading action that is provided by none other than sheepsfoot roller.

Mechanism Of The Sheepsfoot Roller

On cohesive soils, it performs commendably. The compaction of low moisture content soils using a sheepsfoot roller is undoubtedly good enough for other types of machinery. Anyhow, sheepsfoot rollers are also widely utilized in wet circumstances. From the bottom of each lift to the top, the sheepsfoot roller compacts. The kneading action protrudes the spikes into the bottom layers to compact properly.

Applications Of The Sheep foot Roller

Sheeps foot roller contractors are used to compact a variety of soils and aggregates. The most common roller type is a sheepsfoot roller, which compresses the dirt directly beneath the foot tip. It is highly effective in constructing small and large dams due to the fast compaction speed and high pressure delivered to the soils.

Sheepsfoot Rollers Characteristics:

- The ground has a smaller coverage area. Under the lugs on the drum, there should be 8-12 percent ground coverage.

- Pressure on the roller can range from 1400 to 7000 kph.

- Sheepsfoot rollers typically work at speeds of 6-10 km/h.

- Filling the drum with moist sand or another substance can increase the roller pressure on the feet.

- Sheepsfoot roller is a type of roller used to compact vast types of soils. Except for sandy soil, it’s mainly employed for cohesive soils like heavy clays and silty clays.

- Kneading and static weight are two methods of compaction.

- The compacting layer is retained at a thickness of 50 mm (2 inches) or more, depending on the length of the foot.

Different types of Rollers

-

Cylindrical roller

The cylindrical roller is a traditional type of roller that is relatively lightweight and may be handled manually, as it was in the past by animals such as oxen or horses. It’s typically composed of iron and concrete, and it’s around 1.5 meters long and 1 meter wide. Typically, the cylindrical pressure roller is roughly 7 kg/cm2.

-

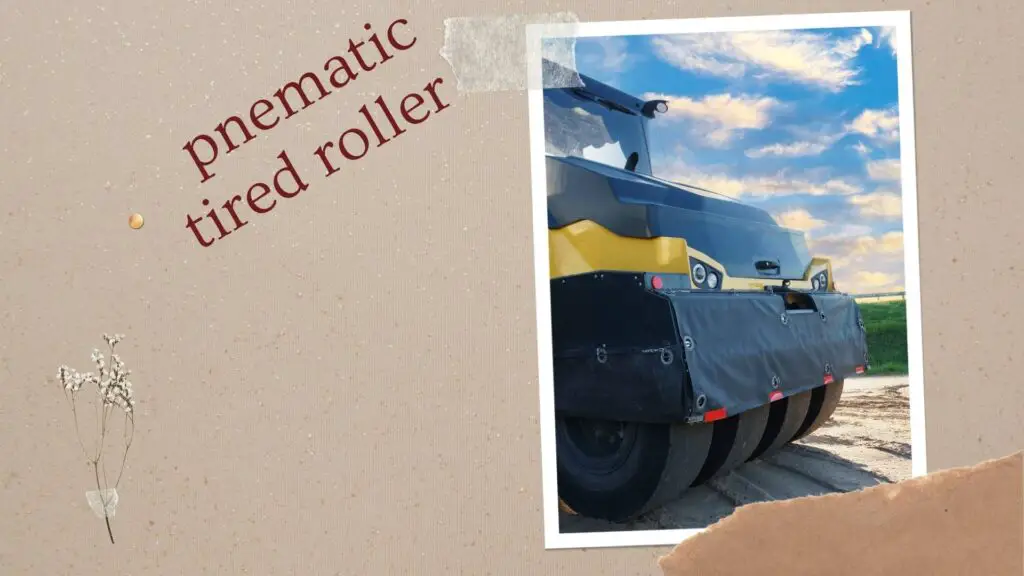

Pneumatic tired roller

Pneumatic rollers, also known as tired pneumatic rollers, are sizeable ride-on rollers with several rows of rubber tires on the front and back ends. The rubber tires cover 80% of the tire’s surface area and maintain consistent pressure throughout the tire’s width.

They’re commonly used for pavements and can help smooth out and polish a project, but they’re also great for loose soil layers and cold-laid bituminous or cold mixed pavements.

See Also: Field Density Test Calculation – A step by Step Guide

-

Vibratory roller

Smooth wheel rollers (including single and double drums) are nearly identical to vibratory rollers, except for one significant difference: vibratory rollers have a specialized vibrating component. The roller will shake as it compacts and flattens the surface.

Because earth, asphalt, and concrete all have natural empty spaces, they can cause a structure to bend and sink, causing structural damage.

The vibratory roller is a great help for maintaining the overall structural integrity of a construction building. The two most prominent soil forms— crushed rock and gravel also good at compacting well.

-

Grid roller

Grid rollers have a grid-like pattern on the steel drum created by a network of steel bars. The grid can be ballasted with concrete blocks or steel attachments for added and much-improved contact pressure. Typically, these rollers are towed or hauled behind a tractor or other large machine.

On compaction activity, the grid pattern on the cylinder drum creates a high contact pressure with minimum kneading action. They’re best used on well-graded, coarse soils, worn rocks, and subgrade and sub-base road projects because of this.

-

Smooth-Wheeled Roller

A smooth wheeled roller has a large steel drum in the front, drums in the back, and one or two wheels. Tandem rollers are three-wheeled rollers with two wheels in the back and one wheel in the front.

See Also: Field Density Test (FDT) 7 Methods and their Comparison

Advantages of using a sheeps foot compactors

- A sheep foot roller is excellent for compacting plastic soil such as silty clay in road construction projects.

- It may be used as both vibration and a static roller to compact fine-grained clay and sand gravel soil.

- It is primarily utilized to produce cohesive soil, except for sandy soils like heavy clays and silty clays. On clayey soils you would not achieve good compaction with steel drum or vibratory rollers.

- The sheep foot roller can compact a portion of the soil layer. It also protrudes to the subsidiary layers. The soil layer should be a minimum of 50mm or more, depending on the length of the foot.

- The sheep foot roller compacts from the bottom to the top of each lift.

- It uses high-speed compaction to compact the soil.

- We can also use the sheep foot roller for compaction in dams, road construction, and pavements.

- We can compact dirt at higher depths using the sheep foot roller. When filling trenches in a tight space adds another level of control. The sheep foot roller has this advantage.

See Also: Field Density Test by Core Cutter Method

Disadvantages

- The biggest con of sheepsfoot roller is that they are ideally utilized in wet situations.

- The compacting soil layer thickness should not be less than 50mm, which varies depending on the length of the foot or protruding lugs.

- The drum should be loaded with moist external materials or sand to boost the roller’s compaction pressure.

- When we utilize a sheep foot roller, we require an experienced driver to control the steering and driving.

Final Thoughts

After knowing about sheetsfoot compactor and other types of compactors, you can choose the one that meets your requirements. The fact that rollers are excellent at upgrading and restoring surfaces means that they are among the most dependable heavy equipment you can utilize on a project. Understanding the advantages of every roller can make selecting the most appropriate one for your job much easier.