Post tension slabs or PT Slabs are concrete slabs in which high-strength steel tendons are placed that are subjected to tension after the slab concrete has been cast and dried. The post tensioning in slabs increase the load-bearing capacity of the structure and also help to counteract deflections. Post tension slabs are ideal to achieve thinner slab sections and where longer spans are required.

Post tension slabs have become popular in architecture, due to their ability to support heavier loads than other types of conventional concrete slabs.

Their resistance to corrosion and high-impact loads makes them ideal choice for places like entrances and plazas where heavy vehicles can be parked or driven on them regularly.

Post tension slabs are becoming increasingly popular due to their superior performance compared to concrete slabs that rest on conventional steel beams and columns.

Despite what you may have heard, though, they’re not the miracle solution to every construction problem. You need to understand their unique characteristics in order to properly use them in your building project.

Let’s take a look at what these post tension slabs are? as well as its advantages and disadvantages, so you can make an informed decision before committing to this new kind of construction.

Meaning of Post tension slabs

We know the slab is a two-dimensional structural element. Unlike beam that takes line loading, slab takes area loading. However, the mechanism or stresses are pretty much similar. We design to take bending stresses or flexural stresses.

Post tension slabs already have negative moment induced in the matrix. That means, the slab itself will not start taking load unless the applied load exceeds the negative stresses induced in the shape of post-tensioning. Hence we call this procedure as prestressing – stressing the slab before applying any service loading.

Also Read: Retrofitting Types – Techniques – Materials- Structures

Thickness and Mix design

Generally for a residential slab system, the thickness of the slab is around 8 inches while the concrete we use is in excess of 3000 psi compressive strength. Anyhow, the tendons are stressed after the concrete has reached almost 75% of the compressive strength for 28 days.

Also Read: What is Prestressed Concrete? – Pre tension – Post Tension -Applications

Pretension slab vs post tension slabs

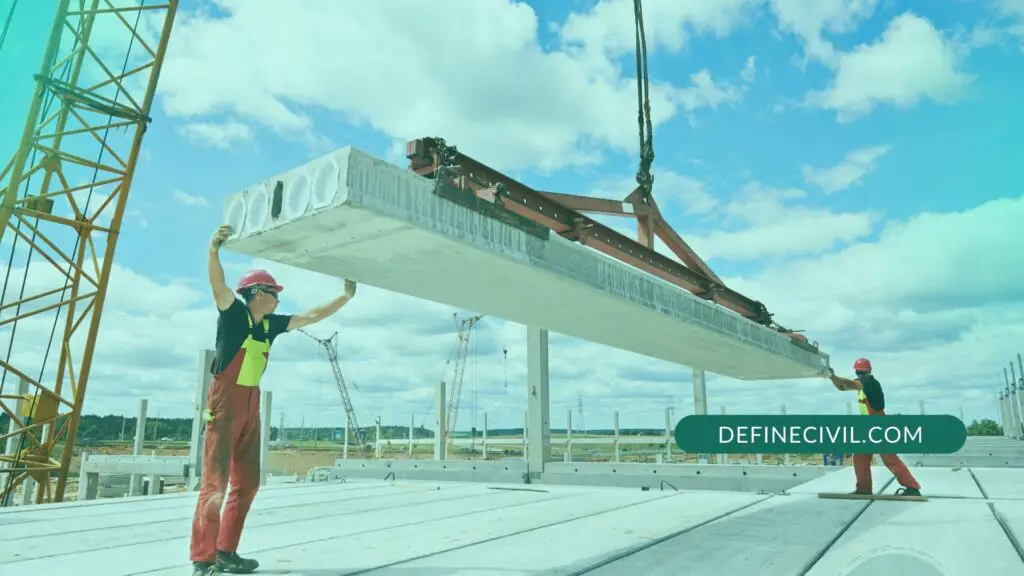

We achieve post tensioning in slab with the help of prestressing steel cables – we call the tendon. During pouring of the post tension slabs, we provide plastic or sheathing ducts. Once the concrete is poured and it has gained its 28 days strength, we commence inserting the tendon from one end to the other. We anchor both the ends and then we start pulling the cables.

In post-tensioning slabs you can either pre-stress the tendon from one end or both ends. If the length of tendon is larger, we must go for post-tensioning from both ends due to losses.

These precast concrete pre- tensioned slabs are also very common. Manufacturers pull the steel tendons before the concrete is poured. That’s what we call as pre-tensioning. So, you see there’s a difference between pretension and post-tension slabs. Anyhow, both are the concepts of prestressing.

Components of post tension slabs

Post tension slabs consist of four main components including

- Duct for post tensioning tendons

- Post-tensioned tendons (the reinforcement material used in concrete)

- Anchors

- Reinforcing steel

Duct

The ducts are placed inside the slabs to allow for the tendons to pass. The purpose of these ducts is to connect cables with tendons. Normally we have metal sheet ducts or plastic ducts to encase steel tendons. Metal sheet ducts are available in 4 to 6 meters length as a standard. You can connect these ducts by external screw coupling and afterwards seal it with PE tape. Anyhow, plastic ducts are water-tight and frictionless.

Tendon

The tendon is a high-strength steel cable that carries tension to a post-tensioned slab. It is made up of one or more numbers of prestressing steel strands coated with protective coating to avoid rusting. These tendons are combinations of wires that are weaved together in multiple numbers.

Typical tendons have 4 or 8 wires. The ends of each tendon are anchored and secured at both ends with a securing device such as an anchor, plate, or toggle bolt.

If the length of tendons is too much, intermediate anchors are provided. Anyhow, the tendon has to follow the standard requirements of ASTM A-416. Typical tendons are in sizes of 0.50 and 0.60 inches in diameter.

Also Read: Waffle Slab – Here’re some advantages and disadvantages

Do you know: the yield strength of a typical rebar is 60,000 psi whereas the yield strength of an ordinary steel strand is about 243,000 psi.

Anchor in Post Tension Slabs

One of the most important aspects of a post tension slab is its anchor. It’s the element that connects the tendon with the concrete. They are embedded in concrete along with the ducts.

Their main function is to provide anchorage thereby transferring the post-tensioning stresses to the concrete. Additional reinforcement is provided along the anchors. In some areas of the world the anchors are also referred to as trumpet cone. It also houses the grouting inlet and outlet pipe to allow grouting of the tendon duct.

Are they cheaper?

One of the key benefits of post-tension slabs is that they are much cheaper than reinforced concrete. The post tension slab does not require heavy rebar or thick concrete in order to provide strength, which makes it a lot more economical.

However, you should be aware that if you plan on constructing an extraordinarily large building and will need a tremendous amount of strength for your building’s foundation, post-tension slabs may not be best for you due to their high cost.

Also Read: Difference between Bridge and Culvert

Applications and uses

Here’re some common areas where you can prefer post-tensioned slabs:

- You can replace reinforced concrete walls, with post-tensioned vertical wall panels. Studies have shown that you can considerably reduce the cost associated with conventional reinforcement. These types of walls are ideal as heavy load-bearing walls.

- In parking lots; where the designers has to rely on heavy-reinforced thick concrete slabs; you can easily use post-tensioned slabs. Designers can use post-tensioned tendons as lateral reinforcements.

- If you’re planning on building a house in an area where you know there are soil conditions that may cause your foundation to move, it might be worth considering using post tensioning slab foundation.

- The use of post-tensioned slabs for bridge decks is not something new. The use of such slabs allows bridges to span longer lengths without the need to have additional piers or supports.

- Post-tensioning slabs has also made it possible to make reinforced concrete as water-retaining structures by preventing cracks and leaks.

Also Read: 9 Types of Concrete Cracks (With Pictures)- Tricks to Prevent – PDF

Benefit of a post tension slab

There’re plethora of benefits and advantages of post-tension slabs:

– Reduced dead weights

Because the optimal usage of concrete strength, we’re able to considerably reduce the dead weight. In one comparison to typical RCC slab, you can expect to have savings on concrete and rebar for about 20 to 30%.

– Reduced cracking and improved durability

Post-tension slabs show reduced cracking, improved durability, and hence lower maintenance costs. Since they won’t deflect under their own loading, so the immediate hair-line cracking is no more observed that is otherwise look odd.

– Popularity

Because of number of benefits, the popularity of post-tensioned slabs has skyrocketed in recent years. Architects, engineering, and contractors prefer this type of structure in their projects. With enhanced technology and continued research, we’re even able to bypass difficulties and shortcomings in post-tensioning systems.

– Save commercial space

Because of the thinner concrete slabs, you can significantly save commercial space. Your floor to floor height can be increased and hence additional floors can be built within same budget.

– Span large lengths

The biggest pro of post-tension slabs is its ability to span large lengths. Previously designers were relying on waffle slabs but with post-tension slabs; you can achieve both benefits of thinner slabs and longer spans. It is a perfect choice for floors of commercial plazas, auditoriums, and shopping centers.

– Lower long-term costs

Because of less maintenance requirements you can save on long term costs. You can enjoy significant energy savings and opportunity to earn LEED credits.

– Improved performance

The post-tension slabs are ideal for structures where you need improved seismic behavior, less vibration, deflection and crack control. These are ideal for waterproofing and flexibility in flooring.

– Fast construction

Because of reduced rebar, it allows you to save considerable time that is otherwise taken up by the rebar fixing. Same stands true with formwork and rebar pouring.

– Material saving

While using post-tensioned slabs, you can use thinner concrete slabs. So, there’re substantial material savings. You can reduce overall usage of concrete by as much as 20% and reinforcement by as much as 75%.

How are they built?

Here’re typical steps for construction of post tensioned slabs:

- Installation of ducts – During the rebar fixing of slab, sheathing ducts are installed as per the profile of the tendon duly approved by the Engineer. Contractors has to strictly follow the profile of the ducts otherwise the design parameters may not be achieved. At the same stage, end-anchorage reinforcement and anchors are also installed with embedded pieces.

- Concreting – Once the rebar and ducts are installed, we’ll fix formwork around the slab as per the thickness and shape. Now we’ll pour the concrete with proper compaction using poker or internal vibrators. The labor must be careful while using vibrator near sheathing to avoid displacement or damage to the sheathing.

- Reeving of tendons: Once the concrete has achieved 28 days compressive cylindrical strength, you’re good to reeve tendons. First we’ll clean the tendons and discard the strand that has rusting on the surface. If the rusting is not deep in the strand, you can use Bristol brush or flower brush to clear the rust anyhow approval of the same is a must. Once you’ve connected the tendons; you can insert the tendons inside the ducts. Spacer plates are used in this step to keep the profile and position of strand same on both ends.

- Post-tensioning: Once the tendons and anchors are fixed; we commence the post-tensioning with mono-jack or hydraulic jack. The post-tensioning force and the stage of the same are duly defined in project specifications. Generally, we stress the tendons at force equal to 80% of the stand’s tensile strength. Normally for a ½ inch grade strand, you can go about 33,000 pounds force. You can use the gauges on the jack to read the induced tension in the tendon.

- Anchoring: After the tensioning has been completed, we anchor the ends of the tendon with the special shaped nuts or anchors.

- Trimming and Grouting: At the end, we trim the extra projecting tendons out of the concrete and pour non-shrink grout in the tendons. The grouting is done to avoid rusting of tendons and to uniformly distribute the tensile stresses to the concrete.

- Once the ducts are grouted, we apply the second stage concrete to the anchor recesses. Anyhow, this step is optional.

Disadvantages of PT slabs

Although few but the PT slabs also has some pitfalls like:

- Being a comparatively new technology, skilled labor is not available. The tensioning jacks are not readily available in developing countries. So, you can’t use post-tension slabs with local workers as they either not have skills nor the tools.

- In case of poor workmanship the entire post-tensioning system will be failed. This can result in significant money loss.

- Tendons when not properly grouted are subject to corrosion. So, it is critical to use high quality material that has been certified by a credible testing agency.

Life span

A lot of homeowners are asking that how long does the post tension slab lasts or if it last more than the conventional reinforced concrete slabs.

A typical post-tensioned slabs can last around 15 to 20 years which is less than that of a conventional slab’s lifespan of 20 to 30 years. So, because of higher failure rate; you need to be careful in picking this technology.

Also Read: Foundation Failure – (Read it before its TOO Late)

Can it fail?

It is highly recommended that you get an engineer involved when building a foundation with post tension slabs. Even if you have some experience in construction, you should consult with an engineer or other expert so that you can be certain that your work is solid and not in danger of failing during future storms or earthquakes.

If your foundation fails, your house will no longer be safe for use and will probably need to be demolished and rebuilt from scratch. In addition, according to Handyman Guide, cleanup costs can be upwards of $250 per cubic yard, depending on whether there is asbestos in any of your materials. It’s definitely not worth taking a risk when it comes to something as important as structural integrity.

Also Read: 5+ Types of Concrete Slabs – Construction – Uses