Understanding the concept of setting time of cement is important while handling concrete like transporting, placing, and compaction. Setting of cement is relevant to concepts like hydration process and hardening.

In normal circumstances, when you are using concrete, you want it in a workable or flow-able condition for pouring in desired shape. That’s because it needs to go deep through the congested rebar and to the corners of the formwork. You also use vibrator to enhance workability. But after lapse of some time, you need concrete to become stiff so you can remove the formwork.

That’s where the concept of setting time of cement comes handy:

What is setting time of cement?

The phenomenon by which cement paste changes from plastic state to solid mass is called setting of cement. The setting of cement takes time. That time which is taken by cement for changing into solid mass is called setting time of cement.

Setting time of cement and concrete is same because cement is the binding material which is made of different compounds that play important part in setting of cement. The knowledge of setting of cement is necessary for quality construction of structures.

Also Read: Compaction factor test for workability of concrete

Cement is mixture that includes lime, silica, alumina, magnesia, iron oxide, Sulphur trioxide. All these ingredients play their role for providing desired properties to cement.

The main ingredients are lime, silica and alumina which are used in large amount. These argillaceous and calcareous materials when burned in rotatory kiln form some major compounds which provide strength to cement, and gypsum is added for increasing the setting time of cement.

Also Read: Harsh Concrete – Reasons and How to improve harsh concrete mix

Stages of setting of cement

The setting process of cement starts when we add water in cement. The setting of cement is divided into three stages.

Hydration of cement

Hydration of cement is a chemical reaction between cement and water. When water is added in cement it reacts with four compounds of cements which are (C3S, C2S, 3CA1, 4CAFe).

The compound which reacts first is 3CAl which is tricalcium aluminate and it plays important part in initial setting of cement.

In hydration process all the four compounds react one by one and get hydrated. Tricalcium silicate (C3S) compound of cement during hydration form complex hydro silicates.

Colloidisation Stage

These compounds during hydration forms a product which separates out in the form of gel which gets thickened slowly and initiate setting of cement. At this point cement becomes fully saturated and takes no water.

Crystallization Stage

As the name suggests in this stage the gel which is formed in previous stage will change into crystals. The compounds which are less stable such as tri calcium aluminate and calcium hydroxide starts changing to stable crystalline state. The calcium hydro silicate gel also continues to harden. The development of crystals and hardening of gel forms a strong and grown mass of crystals and gel.

Setting and hardening of cement both are different conditions of cement.

Hardening of Cement

The phenomena by which cement paste sets and develops strength is called hardening of cement.

Also Read: Types of Cement – Classification based on standards

Setting Time of Cement

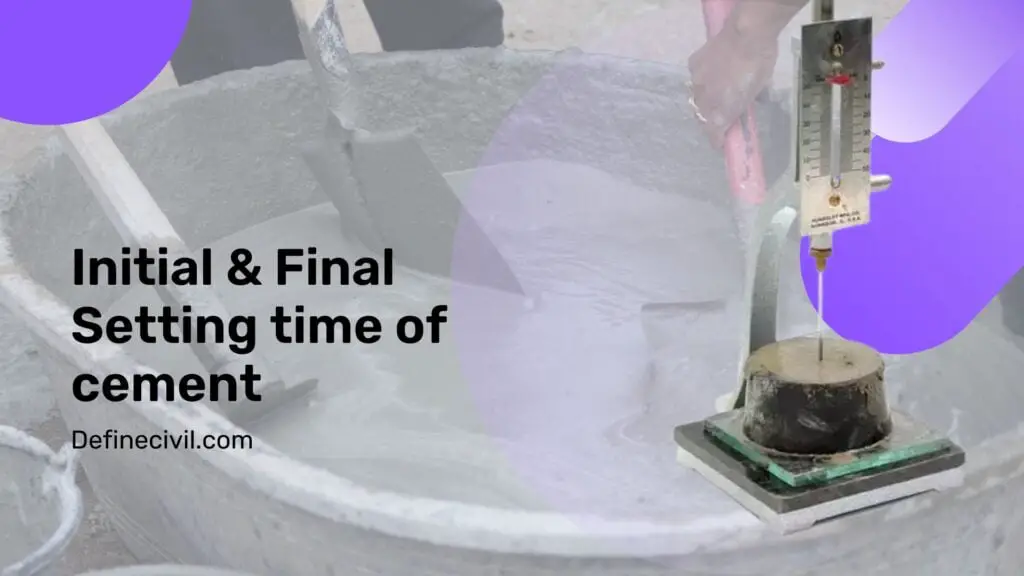

The setting time of cement is a time taken by cement to change from fluid mass into a solid mass. The setting time of cement is found by Vicat apparatus according to ASTM standards. The setting of cement is divided into two stages which are explained below.

- Initial Setting of cement

- Final Setting of cement

The setting time of all types of cements are not same. Some cements set rapidly with less time while some takes more time. The selection of cement for early and late setting depends upon the environmental and type of construction.

Also Read: Fineness of Cement by Blaine’s Air Permeability test

Initial Setting Time of Cement

The initial setting time of ordinary Portland cement is 30-45 minutes. This is the maximum time available for mixing, transportation, placing and compaction of cement concrete on site. Preparation should be made in such way that concrete should be placed within the available time before initial setting.

Also Read: Difference between Cement and Concrete or Mortar

Test for Initial setting time of cement

Apparatus

The initial setting time of cement is found with the help of Vicat apparatus. It consists of assembly and vertical plunger of 40-50mm length and 10mm diameter.

Requirements

Test for setting time is done in laboratory at a room temperature of 25+-2°C with relative humidity of 90%. A sample of cement paste around 500gram will be taken and water added will be equal to 0.85P where P is a percentage of water required for normal consistency.

Procedure

A stopwatch will also be required during this test. After adding water start the stop watch. The normal consistency of cement paste is obtained by adding water from 25 to 35 % by weight of cement. The normal consistency is also found by Vicat apparatus.

Also Read: Soundness Test of Cement by Le-Chatelier Apparatus (BONUS TIPS)

After forming a cement paste place, it in Vicat mold and then start the test. A needle of 1mm^2 cross sectional area will be attached to plunger and needle will be brought in contact with surface of cement paste by lowering the rod. After every 10-minute interval release the rod and note the reading on Vicat apparatus. When the needle penetrates to a cement paste up to depth of 35mm from top or when distance between needle bottom and Vicat mold remains only 5-7mm then that time will be the initial setting time of cement.

Final Setting Time of Cement

The final setting time of ordinary Portland cement is 10 hours or 600 minutes. The information of final setting time is important because it decide the shuttering period and removal of formwork from structures.

Also Read: Physical Properties of Cement to surprise you

Test for Final Setting time of cement

The final setting time of cement is also found by Vicat apparatus. The same paste made for initial setting time will be used for final setting time. Only difference in this test is that it contains needle with cutting edge.

The apparatus needle will be brought in contact with surface of cement and rod will be released again and again until the top surface of cement leaves no impression of cutting edge. The time will be noted. The time taken between adding water in cement to time taken when cutting edge leaves no impression on surface of cement is called final setting time of cement.

Also Read: Rapid Hardening Cement – Properties – Benefits – Uses

Factors Affecting Setting Time of Cement

The factors which affect the setting time of cement are given below

- Ingredients of Cement

- Cement Fineness

- Water Cement ratio

- Type of Admixture

- Amount Of gypsum

- Cement Storage

The knowledge of setting of cement is very important for quality of construction and to deal with various challenges of environment and time.

Also Read: What is Bogues Compounds in Cement and their Significance or Uses

Significance

Initial setting time of cement helps in the handling of concrete process like transport, placing, and compaction. We sometimes need to delay hydration process and hardening by adding sugar to avoid cold joints or other problems at site.

Final setting time of cement is also crucial to harden the concrete and so the formwork can be removed safely.

Requirements

For a normal concrete work and for normal Portland cement, the initial setting time must not be earlier than 45 minutes while the final setting time should not be later than 6.5 hours.

| Type of Cement | Initial Setting Time | Final Setting Time |

| Ordinary Cement | It shall not be less than 30 minutes. | It shall not be more than 10 hours. |

| Rapid Hardening Cement | It shall not be less than 30 minutes. | It shall not be more than 10 hours. |

| Low Heat Cement | It shall not be less than 60 minutes. | It shall not be more than 10 hours. |

Typical values

| Name / type of cement | Description | Indian Standard Reference | Initial Setting time | Final Setting Time |

| OPC (33) | Ordinary Portland 33-grade cement | IS:269 | 30 | 600 |

| OPC (43) | Ordinary Portland 43-grade cement | IS:8112 | 30 | 600 |

| OPC (53) | Ordinary Portland 53-grade cement | IS:12269 | 30 | 600 |

| SRC | Sulphate Resistant Cement | IS:12330 | 30 | 600 |

| PPC | Portland Pozzolana Cement | IS:1489-P1 | 30 | 600 |

| RHPC | Rapid Hardening Portland Cement | IS:8041 | 30 | 600 |

| PSC | Portland Slag Cement | IS:455 | 30 | 600 |

| High Alumina | IS:6452 | 30 | 600 | |

| Super Sulphated | IS:6909 | 30 | 600 | |

| Low Heat | IS:12600 | 60 | 600 | |

| Masonry Cement | IS:3466 | 90 | 1440 | |

| IRS-T-40 | Railway | 60 | 600 |

Important Questions / FAQs

How we can increase the setting initial setting time of cement?

Initial setting time of cement increases by adding Calcium Sulphate (CaSO4). It is a type of gypsum that works to delay the setting time of cement. All cements we have in market have gypsum in some portion to control the otherwise rapid or flash set. These chemicals are called retarders as they work opposite to accelerators.

Also Read: Specific Gravity of Cement – Definition – Test – Procedure

How we can decrease the setting time of cement?

The setting time of cement decreases by adding CaCl2 (Calcium Chloride) that means the cement will take less time to become hard. Calcium chloride works like an accelerator that reduces the setting time. It helps protect freshly placed concrete. You may need to use accelerator while pouring concrete in cool temperatures like below 70°F.

Further Read: Cement Concrete Calculator – Online calculate cement sand and aggregate

Quiz

- Hardening of cement occurs at _________________

- rapid rate during the first few days and afterwards it continues to increase at a decreased rate

- slow rate during the first few days and afterwards it continues to increase at a rapid rate

- uniform rate throughout its age

- none of these.

- quick setting cement is produced by adding ___________________

- Aluminum sulphate

- Gypsum

- Both

- None of above